| Technical Specifications | |

|---|---|

| Material thickness | 2.0 mm |

| Roller stations | 20 stations |

| Roller material | Cr12, HRC 58-62° |

| Shaft diameter | Ø 80 mm, material 40Cr |

| Main motor power | 22 kW × 2 sets |

| Hydraulic cutting power | 11 kW |

| Forming speed | 5–15 m/min |

| Drive way | Gearbox drive |

| PLC Control Box | Delta, Taiwan |

| Encoder | Omron, Japan |

| Inverter | Mitsubishi, Japan |

| Power supply | 380V, 50 Hz, 3-phase (as per requirement) |

Product Overview

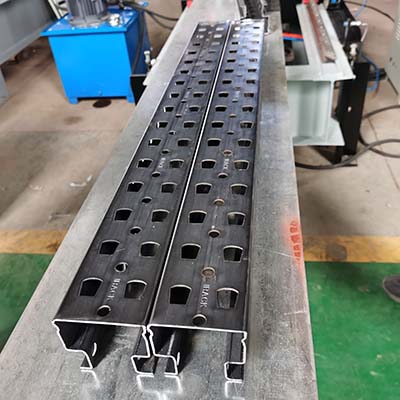

Our Warehouse Rack Upright Roll Forming Machine, also known as a rack “upright / upright-column” roll forming machine, is specifically designed to produce upright frames for warehouse pallet racking systems. The full production line includes a decoiler, leveler, press punch, main forming machine, hydraulic cutting unit, control box, and out-table — delivering a highly automated solution. Warehouse Shelving Rack Upright Roll‑Forming Line

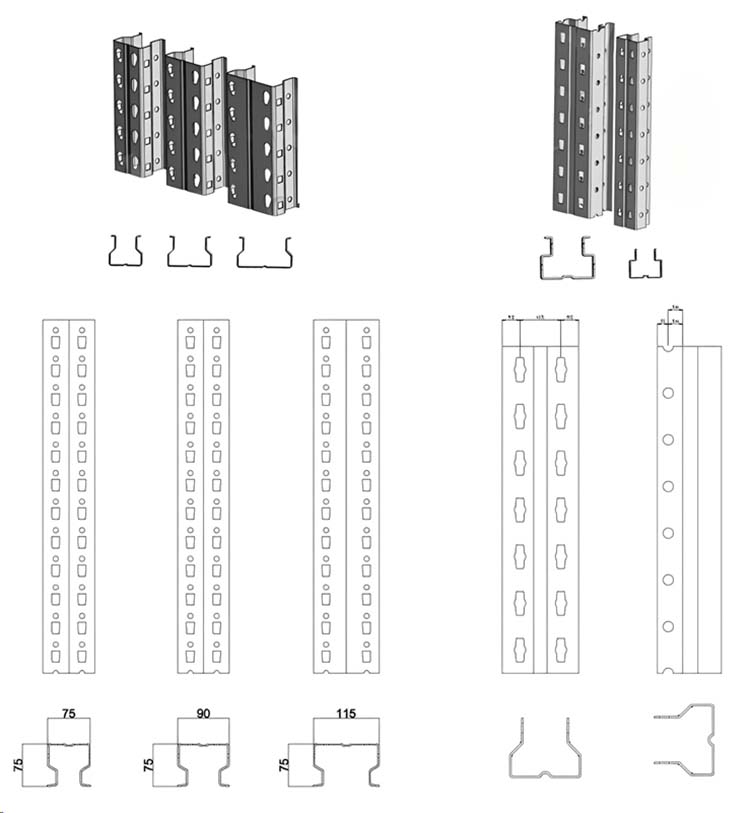

Customizable Upright Profiles

The machine supports adjustable and custom dimensions: both the thickness and size of the rack upright can be tailored to your needs. We can produce uprights with a maximum thickness up to 3.0 mm, depending on the design and load requirements.

| Technical Specifications | |

|---|---|

| Material thickness | 2.0 mm |

| Roller stations | 20 stations |

| Roller material | Cr12, HRC 58-62° |

| Shaft diameter | Ø 80 mm, material 40Cr |

| Main motor power | 22 kW × 2 sets |

| Hydraulic cutting power | 11 kW |

| Forming speed | 5–15 m/min |

| Drive way | Gearbox drive |

| PLC Control Box | Delta, Taiwan |

| Encoder | Omron, Japan |

| Inverter | Mitsubishi, Japan |

| Power supply | 380V, 50 Hz, 3-phase (as per requirement) |

Hole & Slot Design

During roll forming, teardrop-style holes and slots can be punched into the upright profile, enabling easy installation of load-bearing beams later. This feature ensures compatibility with a variety of beam types.

Material Options

We offer broad material compatibility, including:

Cold-rolled steel

Galvanized coil

PPGI

Carbon steel

Stainless steel

Aluminum

Automated Workflow

The production line is fully automated: after setting parameters on the touchscreen, the machine executes uncoiling → leveling → feeding → punching → forming → cutting without manual intervention, boosting accuracy and efficiency.

Global Experience & Service

We have considerable export experience and have supplied Pallet Racking Roll Forming Machines to markets such as Mexico, Peru and more.

We also provide one-on-one service, customizing each machine to your drawings, dimensional tolerances, and budget.

Why Choose Us

Proven design expertise: we can adapt to different loading and design needs

Precision‐engineered profiles that meet safety and strength requirements

Reliable after-sales support, from installation to training