| Parameter | Specification |

|---|---|

| Raw material | Cold-rolled steel, Galvanized steel (customizable) |

| Material thickness | ~ 0.5 – 1.2 mm (depending on panel design) |

| Material width / Adjustable width | Adjustable — per panel width requirements |

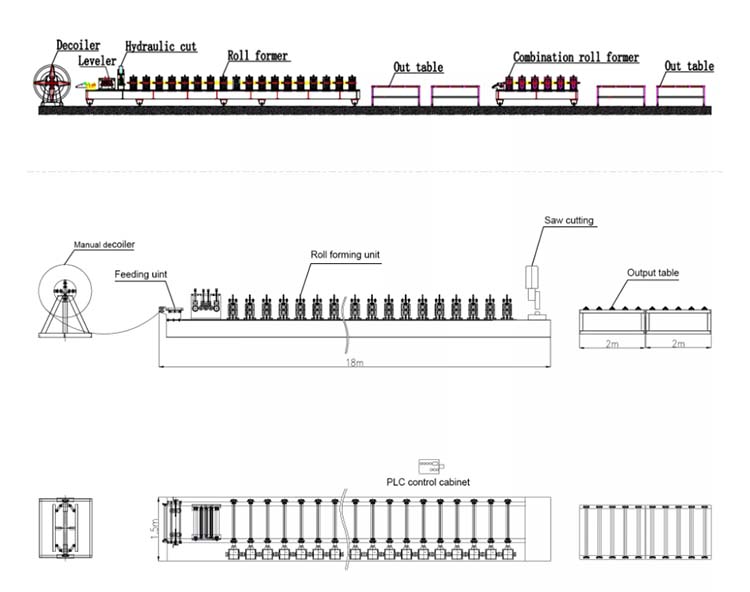

| Production line configuration | Decoiler → Leveler/Straightener → Servo Feeding & Punching → Roll Forming Mill → Hydraulic Cutting/Bending → Output Table |

| Forming stations (roller stands) | ~ 18 – 24 stations (depending on profile complexity) |

| Production speed | 6 – 15 m/min (depending on material & configuration) |

| Cutting & bending system | Hydraulic cutting + optional bending/edge forming; auto length measuring by encoder |

| Control system | PLC + HMI touchscreen — auto length/quantity control, auto start/stop |

| Customization options | Panel width, thickness, profile design, punching/bending, material type — customizable |

| Typical applications | Supermarket shelving panels, warehouse/storage rack panels, retail shelving, industrial storage systems |

Our Shelving Base Panel Roll Forming Machine is engineered to automate the continuous production of metal shelf panels for supermarkets, warehouses, retail stores, and industrial storage systems. Whether you need simple flat panels or structured shelving panels with slots/holes, this machine delivers high-quality, consistent output — ideal for mass production with minimal manual labor.

Full production line integration — decoiler, leveling / straightening device, servo feeder & punching device, roll forming mill, hydraulic cutting / bending, and output station, forming a complete automatic line.

Material compatibility — suitable for galvanized steel or cold-rolled steel coils.

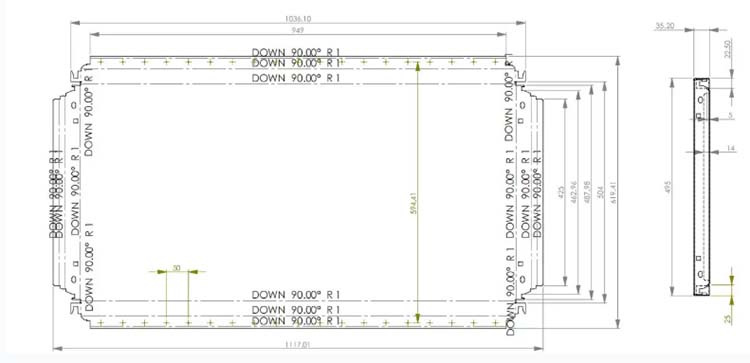

Adjustable width & customizable profiles — able to accommodate different panel widths and shelving panel designs, per customer requirements.

Automated punching, forming & cutting — online punching or slot/notch punching, forming through multiple roll-stations, and automatic hydraulic cutting (and optional bending), all under PLC/HMI control — reducing manual work and ensuring precision.

High efficiency and output consistency — continuous roll forming process ensures steady production and uniform shelf panels suitable for retail or industrial racks.

Flexible control & safety — PLC + touchscreen / HMI for setting length, quantity, and automatic stop after batch completion; machine frames and protective covers for safety and long service life.

| Parameter | Specification |

|---|---|

| Raw material | Cold-rolled steel, Galvanized steel (customizable) |

| Material thickness | ~ 0.5 – 1.2 mm (depending on panel design) |

| Material width / Adjustable width | Adjustable — per panel width requirements |

| Production line configuration | Decoiler → Leveler/Straightener → Servo Feeding & Punching → Roll Forming Mill → Hydraulic Cutting/Bending → Output Table |

| Forming stations (roller stands) | ~ 18 – 24 stations (depending on profile complexity) |

| Production speed | 6 – 15 m/min (depending on material & configuration) |

| Cutting & bending system | Hydraulic cutting + optional bending/edge forming; auto length measuring by encoder |

| Control system | PLC + HMI touchscreen — auto length/quantity control, auto start/stop |

| Customization options | Panel width, thickness, profile design, punching/bending, material type — customizable |

| Typical applications | Supermarket shelving panels, warehouse/storage rack panels, retail shelving, industrial storage systems |

Supermarket shelving panels and store display racks

Warehouse & storage shelving systems

Retail shelving, shop racks, storage units

Industrial storage shelving and rack system

Comprehensive, one-stop production line — from coil to finished shelf panel.

Customizable according to customers’ panel design, width, thickness, and slot/punch requirements.

Automated processes reduce labor costs, increase output and ensure consistent quality.

Wide applicability — from supermarkets to heavy-duty warehouse racks.