| Parameter | Specification |

|---|---|

| Raw material | Cold-rolled steel / Galvanized steel |

| Material thickness | 1.5 – 2.5 mm (some models support 1.0–2.5 mm) |

| Material width / Coil width | Customizable depending on beam/rack profile (e.g. 100–500 mm) |

| Forming stations | 16 – 28 stations (depending on profile complexity) |

| Forming / Line speed | 8 – 20 m/min (typical 10–15 m/min) |

| Roller material | GCr15 / GCr12 bearing or mould steel — quenched, hardened and chrome-treated |

| Shaft / Roller shaft diameter | φ70–φ80 mm (depending on configuration) |

| Drive / Transmission system | Gearbox drive or Chain drive (or worm-gear/gearbox + chain) |

| Cutting system | Hydraulic cutting / post-cutting / flying shear — automatic cut-to-length |

| Control system | PLC + HMI / Touch-screen — automatic length, quantity, forming & cutting control |

| Output product types | Shelf beams, rack beams, upright posts, storage rack components for warehouses, supermarkets, industrial racks |

Our Storage Rack Shelf Beam Roll Forming Machine is specially designed to produce high-quality shelf beams, uprights, and shelving rack components for warehouses, supermarkets, and industrial storage systems. With full automation from coil feeding to final cut-to-length beams, this machine enables efficient, consistent, and high-volume production of storage rack parts.

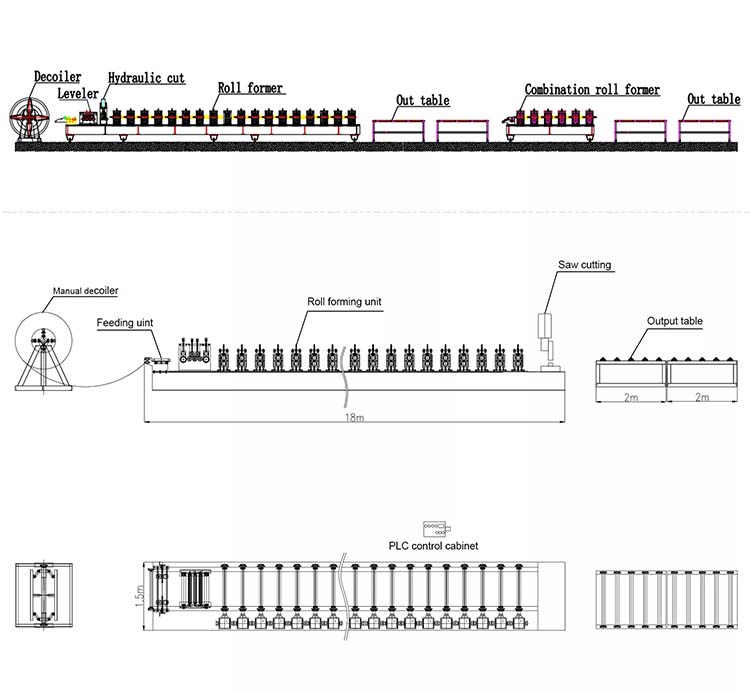

Fully integrated production line — The line includes decoiler, feeding and leveling unit, servo feeder & punching device, precision roll forming mill, hydraulic cutting/bending, and output/receiving table — forming a complete production process for storage rack beams and shelving components.

High efficiency and automation — Minimal manual operation required; the roll forming process is continuous and controlled, greatly reducing labor and improving productivity.

Stable quality and consistency — Precision rollers, hardened and wear-resistant components, and accurate servo feeding & punching ensure uniform beam profiles and repeatable dimensional accuracy for each batch.

Customizable profiles & flexibility — The machine supports different steel materials (cold-rolled, galvanized, etc.), variable thickness and width, and can be configured to produce a variety of rack profiles (beams, uprights, slotted posts, boxed beams) according to customer requirements.

Cost-effective mass production — High-speed roll forming and automated cutting reduce production time and waste, lowering per-unit costs and enabling competitive pricing for shelving components.

| Parameter | Specification |

|---|---|

| Raw material | Cold-rolled steel / Galvanized steel |

| Material thickness | 1.5 – 2.5 mm (some models support 1.0–2.5 mm) |

| Material width / Coil width | Customizable depending on beam/rack profile (e.g. 100–500 mm) |

| Forming stations | 16 – 28 stations (depending on profile complexity) |

| Forming / Line speed | 8 – 20 m/min (typical 10–15 m/min) |

| Roller material | GCr15 / GCr12 bearing or mould steel — quenched, hardened and chrome-treated |

| Shaft / Roller shaft diameter | φ70–φ80 mm (depending on configuration) |

| Drive / Transmission system | Gearbox drive or Chain drive (or worm-gear/gearbox + chain) |

| Cutting system | Hydraulic cutting / post-cutting / flying shear — automatic cut-to-length |

| Control system | PLC + HMI / Touch-screen — automatic length, quantity, forming & cutting control |

| Output product types | Shelf beams, rack beams, upright posts, storage rack components for warehouses, supermarkets, industrial racks |

Decoiler → Feeding & Leveling → Servo Feeding & Punching (if needed) → Roll Forming Mill → Hydraulic Cutting / Bending → Finished Shelf Beams / Components → Receiving / Output Table

Warehouse pallet racks and storage systems

Supermarket shelving and store racks

Industrial storage racks and heavy-duty shelving

Retail shelving and display storage

Any modular storage rack systems requiring strong, consistent metal beams and structural components

Complete automated line from raw coil to finished shelf beam — significantly reduces manual labor and simplifies workflow.

Strong, durable construction — hardened rollers and stable frame ensure long-term, stable production with minimal maintenance.

High flexibility — easily adapts to different rack designs, materials, thicknesses, and customer specifications.

High quality and consistency — precise forming and cutting ensure reliable, repeatable products suitable for professional rack assembly.

Cost-effective mass production — reduces labor cost, material waste, and unit cost, enabling competitive product pricing and efficient output.