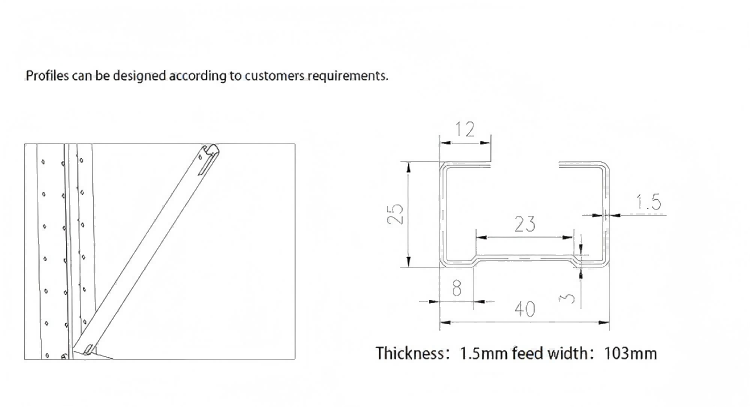

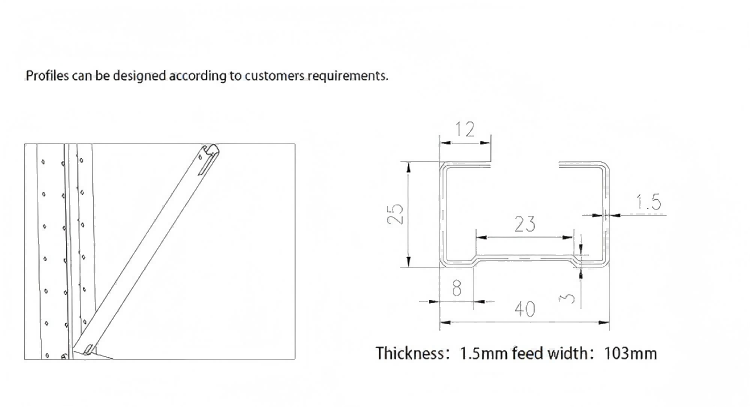

This high-performance rack bracing roll forming machine is a dedicated solution for manufacturing C-section uprights that form the backbone of stable, high-capacity storage rack systems. It offers broad material compatibility, processing Galvanized Coil (1.5-1.8MM thickness, customizable per customer request), PPGI, PPGL, Cold-rolled Steel and Carbon Steel with ease. Targeting materials with Yield Strength of 250 - 350 Mpa and Tensil Stress of 350 Mpa-500 Mpa, it ensures the formed rack uprights possess excellent structural strength and load-bearing capacity.

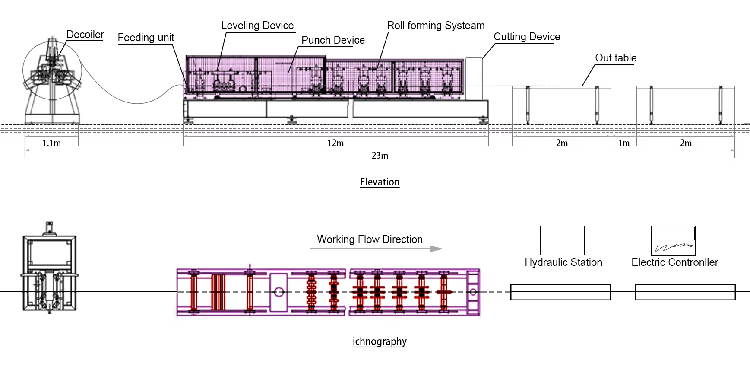

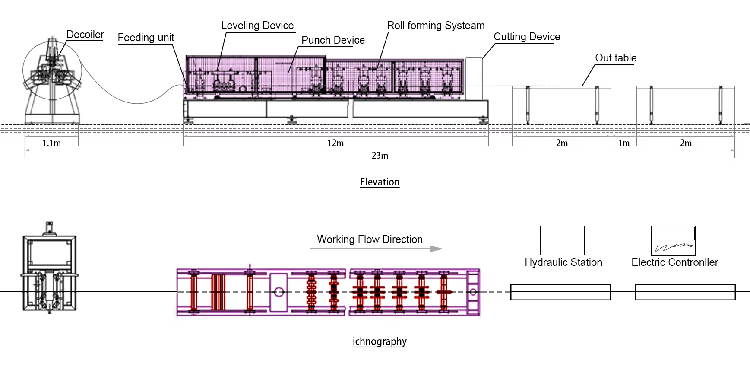

The machine delivers efficient production with a Nominal Forming Speed of 10-15 M/Min (adjustable as needed) and approximately 14 Forming Stations (customized according to profile drawings), enabling manufacturers to meet tight delivery schedules without compromising quality. The decoiling unit provides a Manual Decoiler as standard, with an optional Hydraulic Decoiler to automate material feeding and reduce labor costs. The driving system includes a standard Chain Drive for reliable operation, with an optional Gearbox Drive for applications requiring precise speed synchronization. Built with a Steel Plates Welded structure, the machine can be upgraded to Cast Iron Stands for enhanced rigidity and vibration resistance during high-speed forming.

|

C Bracing Section Roll Forming Machine

|

|

Machinable Material

|

A) Galvanized Coil

|

Thickness(MM):1.5-1.8 as per customer

|

|

|

B) PPGI,PPGL

|

|

|

|

C) Cold-rolled Steel

|

|

|

|

D) Carbon Steel

|

|

|

Yield Strength

|

250 - 350 Mpa

|

|

Tensil Stress

|

350 Mpa-500 Mpa

|

|

Nominal Forming Speed(M/Min)

|

10-15

|

* Or According To Your Requirment

|

|

Forming Station

|

About 14

|

* According To Your Profile Drawings

|

|

Decoiler

|

Manual Decoiler

|

* Hydraulic Decoiler (Optional)

|

|

Driving System

|

Chain Drive

|

* Gearbox Drive (Optional)

|

|

Machine Structure

|

Steel Plates Welded

|

* Cast Iron Stands (Optional)

|

|

Rollers’ Material

|

GCr 15

|

* Cr12Mov (Optional)

|

|

Cutting System

|

Hydraulic Pre-cut

|

|

Punching System

|

Hydraulic Punching

|

|

Frequency Changer Brand

|

Yaskawa

|

* Siemens (Optional)

|

|

Power Supply

|

380V 50Hz

|

* Or According To Your Requirment

|

|

Machine Color

|

Industrial Blue

|

* Or According To Your Requirment

|

Rollers are made of GCr 15 as standard (optional Cr12Mov rollers for superior wear resistance), ensuring long service life and consistent profile accuracy. The Hydraulic Pre-cut System and Hydraulic Punching System enable one-step forming, cutting and punching, improving production efficiency significantly. A Yaskawa frequency changer is equipped for smooth speed adjustment, with Siemens available as an optional alternative. The machine operates on 380V 50Hz power (customizable to local electrical standards) and features an industrial blue finish, with color customization options to match your factory or brand aesthetic.