Product Overview

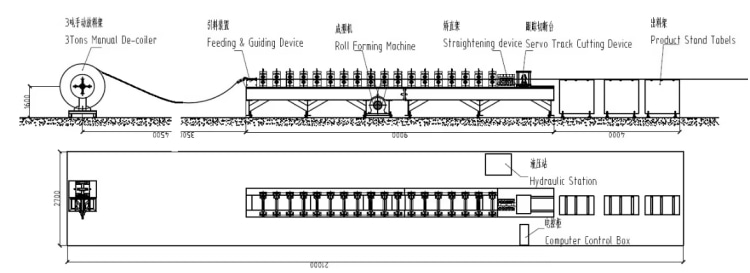

The Metal Shelf Storage Rack Beam Machine is a high-efficiency automated production equipment specifically designed for manufacturing precision metal shelf beams. As a core device in the storage rack manufacturing industry, it integrates decoiling, automatic feeding, precision punching, continuous roll forming, and high-precision cutting into a seamless workflow. Equipped with advanced core components and intelligent control systems, this machine ensures stable and consistent mass production of high-quality shelf beams, perfectly meeting the storage needs of industrial warehouses, logistics centers, and commercial storage facilities. It is widely trusted by global rack manufacturers for its reliable performance and efficient production capacity.

Core Technical Specifications

-

Raw material: Cold-rolled steel, Galvanized steel (optional stainless / color-coated steel)

-

Material thickness: 1.5 – 3.0 mm

-

Roller material: GCr15 (or optional Cr12) alloy steel, heat treated (quenched / hardened)

-

Roller hardness: HRC 58 – 62° (depending on heat treatment)

-

Number of forming stations: 16 – 28 stations (profile dependent)

-

Forming (line) speed: 5 – 15 m/min (depending on profile & configuration)

-

Main motor power: 15 – 22 kW (depending on model)

-

Cutting / Shearing system: Hydraulic cutting (or saw-cut); cutting blades made of heat-treated Cr12 / Cr12MoV

-

Control system: PLC control (Siemens / Panasonic / Delta optional) — supports automatic forming, punching, cutting, length & quantity control

-

Decoiler: Manual or hydraulic decoiler (capacity configurable, e.g. 3t–5t)

-

Material width: As per customer’s profile drawing / specification

-

Profile types: Upright rack columns / shelf upright posts / pallet rack uprights / warehouse shelving uprights

-

Power supply / Voltage: 380 V, 50 Hz, three-phase (customizable per customer requirement)

Key Product Advantages

1. High-Precision Forming: Adopting high-hardness heat-treated alloy steel rollers and multi-station forming design, the machine ensures uniform stress distribution during forming, achieving excellent dimensional accuracy and smooth surface finish of shelf beams, which lays a solid foundation for the stability of the entire storage rack.

2. Efficient Integrated Production: The integrated workflow eliminates intermediate manual transfer links, greatly reducing production time. With a forming speed of 5-15 m/min, it can efficiently meet large-batch production demands and significantly improve production efficiency.

3. Intuitive Operation & Safety: Equipped with a professional PLC control system, the machine supports full-automatic production control, with a user-friendly interface that simplifies operation. The comprehensive safety protection system (emergency stop, safety guard, fault monitoring) ensures the safety of operators and production.

Quality & Safety Assurance

All components of the machine undergo strict quality inspection and performance testing before leaving the factory, complying with international industrial standards. It has obtained authoritative certifications such as CE and ISO9001:2015, providing customers with reliable quality guarantees. The full-process safety monitoring mechanism effectively avoids production accidents.

Global Service Support

We provide one-stop services including pre-sales technical consultation, on-site layout planning, customized solutions, on-site installation and commissioning, and 24/7 after-sales technical support. Professional engineers team ensures that customers can use the equipment smoothly.

Typical Applications

Widely used in the production of shelf beams for industrial storage racks, logistics distribution center racks, commercial supermarket storage racks, and cold-chain storage racks.