Xinnuo Heavy Duty Rack Upright Roll Forming Machine: Power Meets Precision

As a cornerstone product of Hebei Xinnuo Roll Forming Machine Co., Ltd.—a pioneer with 25+ years in roll forming technology and a reputation for engineering excellence—Xinnuo’s Heavy Duty Rack Upright Roll Forming Machine redefines efficiency and reliability for industrial storage rack manufacturing. Tailored to meet the rigorous demands of large-scale warehouses, logistics distribution hubs, and heavy-industry facilities (such as automotive and construction material storage), this machine transforms raw steel coils into high-performance uprights that form the load-bearing backbone of durable storage systems. Backed by Xinnuo’s R&D team of 50+ engineers, it embodies the brand’s commitment to merging global technology standards with practical industrial needs.

Engineered for uncompromising power and micron-level precision, it processes 0.8-3.0mm thick galvanized, high-strength carbon, or stainless steel coils (width 300-600mm) with exceptional consistency. Its 22 hardened steel rollers (52HRC hardness) feature a special chrome-plated finish, ensuring uniform shaping without scratching material surfaces while delivering uprights with a dimensional tolerance of ±0.3mm—critical for seamless rack assembly and long-term structural stability under heavy loads (up to 5,000kg per upright). A 22kW high-efficiency motor, paired with an energy-saving inverter, drives production at 10-15m/min, balancing rapid output with uncompromised quality control.

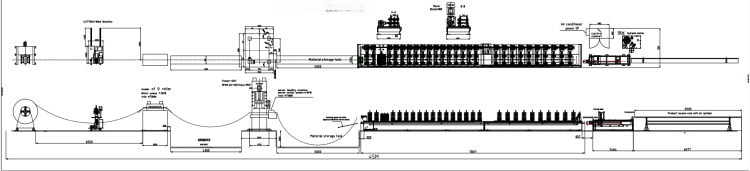

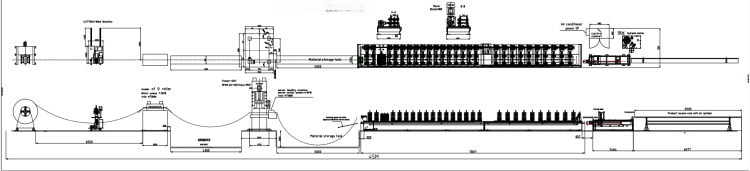

Intelligence is embedded in every component: a Siemens PLC control system with a 7-inch touchscreen HMI allows operators to preprogram 100+ custom profiles, monitor real-time data (including speed, output, and error alerts), and switch between specifications in under 5 minutes—no specialized coding skills required. The fully automated workflow integrates a 5-ton hydraulic decoiler (with coil centering function), precision leveling (to eliminate material warpage), high-speed hydraulic punching (for beam connection holes with ±0.1mm accuracy), roll forming, and servo-driven flying cutting. This seamless process reduces labor requirements from 3 workers to 1, cutting labor costs by 65% and minimizing human error.

Built to withstand continuous industrial use, the machine features a 6.5-ton reinforced welded steel frame (7.5×1.0×1.5m) with anti-vibration pads, guaranteeing stability during 24/7 operation. Wear-resistant roller surfaces and self-lubricating components extend service life by 30% compared to standard models, reducing maintenance downtime. CE, ISO 9001, and TUV certifications ensure compliance with EU and American industrial standards, supporting its trusted presence in 50+ countries, from Germany’s automotive warehouses to Australia’s logistics centers.

Backed by Xinnuo’s 24/7 technical support (via online remote assistance and on-site service in key regions), free on-site installation, and a 1-year warranty (extendable to 3 years), this machine delivers tangible business value. Customers report 40% higher output than manual production, 5% lower material waste due to precise cutting, and a fast ROI of 10-12 months. Whether producing C-section, U-section, or custom uprights for adjustable heavy-duty racks, it’s the trusted choice for businesses scaling their storage component manufacturing efficiently and reliably.