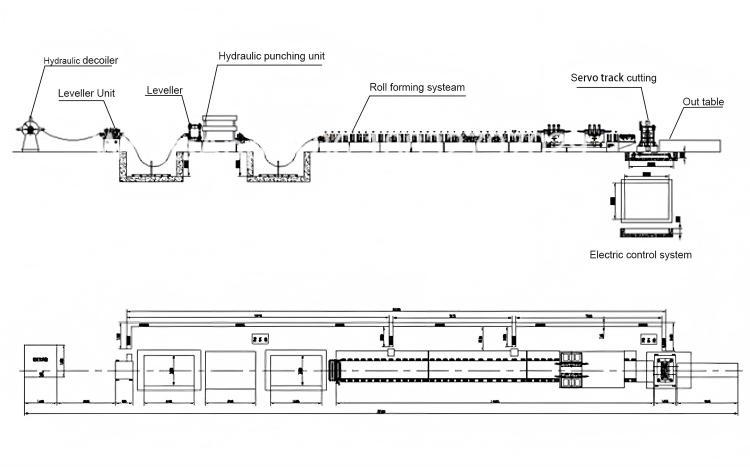

Xinnuo Steel Box Plate Making Roll Forming Machine

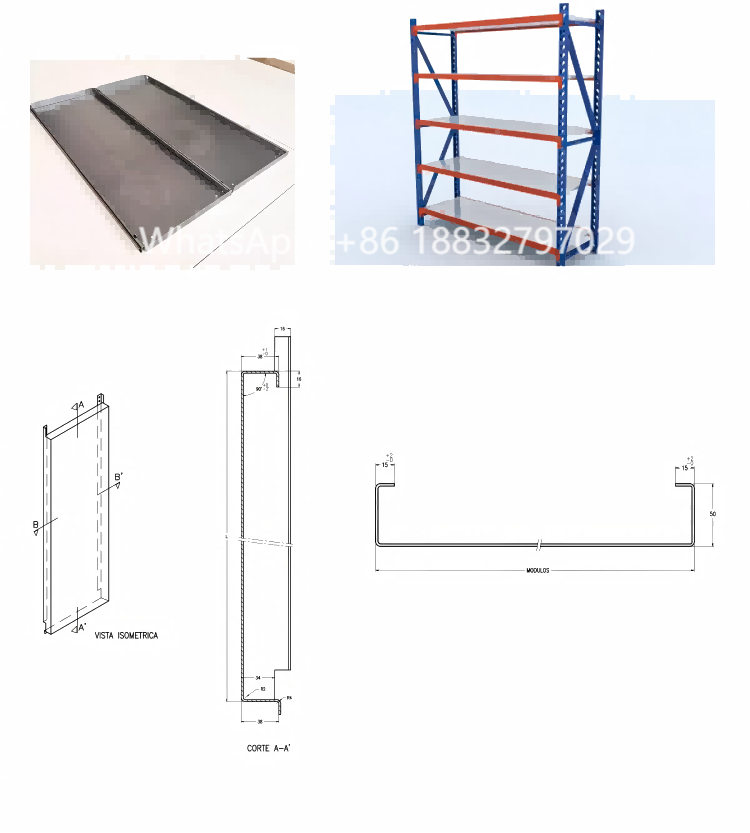

Xinnuo’s Steel Box Plate Making Roll Forming Machine, also known as Supermarket Shelf Panel Roll Forming Machine, is specialized in producing shelf panels with product display card positions—key components for supermarket shelving that bear goods while showing product information and prices. This intelligent equipment is designed to meet the diverse size demands of shelf panels in retail scenarios.

|

Steel Box Plate Making Roll Forming Machine

|

|

Machinable Material

|

A) Galvanized Coil

|

Thickness(MM):0.5–0.8 as per customer

|

|

|

B) PPGI,PPGL

|

|

|

|

C) Cold-rolled Steel

|

|

|

|

D) Carbon Steel

|

|

|

Yield Strength

|

250 – 350 Mpa

|

|

Tensil Stress

|

350 Mpa–500 Mpa

|

|

Nominal Forming Speed(M/Min)

|

3–10

|

* Or According To Your Requirement

|

|

Forming Station

|

About 18

|

* According To Your Profile Drawings

|

|

Decoiler

|

Manual Decoiler

|

* Hydraulic Decoiler (Optional)

|

|

Driving System

|

Chain Drive

|

* Gearbox Drive (Optional)

|

|

Machine Structure

|

Steel Plates Welded

|

* Cast Iron Stands (Optional)

|

|

Rollers’ Material

|

GCr 15

|

* Cr12Mov (Optional)

|

|

Cutting System

|

Hydraulic Pre-cut

|

* Hydraulic Post Cut (Optional)

|

|

Frequency Changer Brand

|

Yaskawa

|

* Siemens (Optional)

|

|

Power Supply

|

380V 50Hz

|

* Or According To Your Requirement

|

|

Machine Color

|

Industrial Blue

|

* Or According To Your Requirement

|

The machine excels in flexibility and efficiency, capable of manufacturing various shelf panel sizes with a thickness range of 0.5-0.8mm, and can be adjusted for thicker materials as needed. It integrates a full set of automated processes on one production line, including uncoiling, feeding, roll forming, punching, cutting, and bending, significantly reducing manual intervention and ensuring consistent production quality.

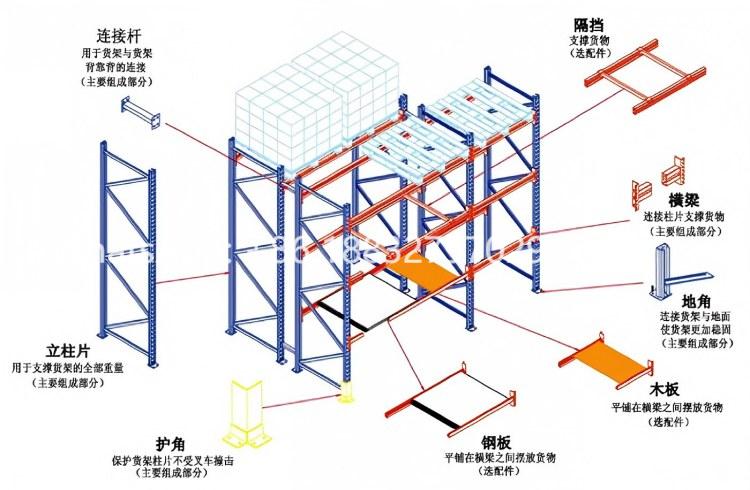

As a comprehensive solution provider for storage systems, Xinnuo complements this machine with supporting equipment such as step beam, upright rack, and box beam roll forming machines—covering all core components of pallet racking systems. This enables customers to build integrated production lines for complete rack systems, optimizing operational efficiency.

We prioritize customer-centric customization, offering professional one-on-one services to tailor solutions based on specific drawings, tolerance requirements, and budgets. Backed by Xinnuo’s strict quality control, whichever configuration you choose, the machine guarantees perfectly functional shelf panel profiles, making it an ideal choice for supermarket shelving manufacturers and warehouse storage solution providers.