Product Description

Product Overview

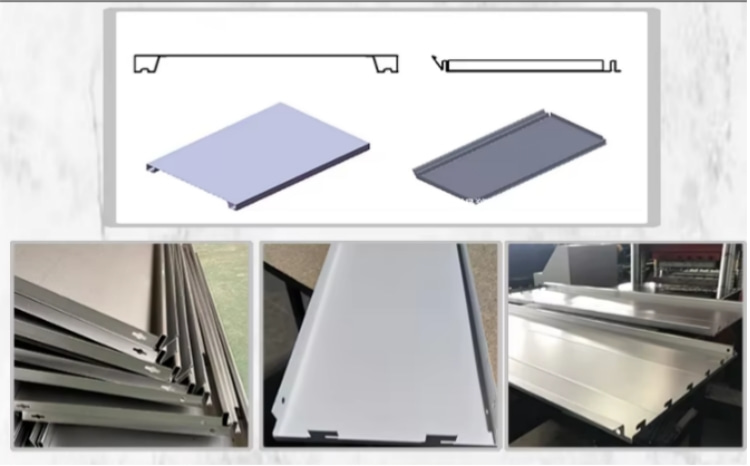

Our Automatic Shelves Panel Roll Forming Machine is professionally developed to cater to the production needs of high-quality shelves panels for modern warehouses, supermarkets, and convenience stores. From the heavy-duty mechanical framework to the smart control module, every component is meticulously designed to deliver precision forming, energy efficiency, and stable performance, becoming a core production asset for shelves manufacturers worldwide.

The machine is equipped with a detachable roller set crafted from imported Swedish alloy steel. After nitriding and quenching treatment, the roller surface hardness reaches HRC62 or above, ensuring consistent forming quality when processing 1.0–2.5 mm galvanized steel, cold-rolled steel, or color-coated steel sheets. The detachable design enables fast roller replacement within 25 minutes, significantly improving production efficiency for multi-specification shelves panels.

Technical Advantages

High-Precision Forming System: Adopting Mitsubishi servo motors and Siemens PLC control system, the machine maintains forming accuracy within ±0.2 mm and ensures the flatness of shelves panels is below 0.4 mm, fully complying with the strict standard of GB/T 3091-2015.

Integrated Forming & Trimming: The integrated online forming and servo trimming process eliminates the need for secondary processing, reducing the total production cycle by 50% and minimizing material waste to less than 2%.

Superior Productivity: One single machine can produce up to 150 sets of shelves panels per day, which is three times the output of traditional semi-automatic production lines, effectively meeting large-order demands.

Safety & Quality Assurance

To guarantee operator safety and product consistency, the machine is integrated with dual infrared safety sensors that trigger an automatic stop within 0.08 seconds when foreign objects intrude. A high-definition visual inspection system monitors the surface and dimensions of finished panels in real-time, automatically rejecting non-conforming products. This ensures stable and high-quality output throughout the entire production process.

Material Compatibility

The Automatic Shelves Panel Roll Forming Machine supports a variety of materials, including galvanized steel sheets, cold-rolled steel sheets, and color-coated steel sheets with thickness ranging from 1.0–2.5 mm. Through advanced constant-temperature control and adaptive roller pressure technology, it perfectly preserves the integrity of the material coating, enhances the corrosion resistance of finished panels, and extends their service life. This makes the machine ideal for producing shelves panels for dry warehouses, food storage facilities, and pharmaceutical logistics centers.

|

Model number

|

Rack Shelf Roll Forming Machine

|

|

Material Thickness

|

0.7-1.5mm

|

|

Product speed

|

3-5meter / per minute

|

|

Roller Stations

|

About 16 stations

|

|

Roller Material

|

Gcr15 Steel with quenching

|

|

Shaft Material

|

45# high quality steel

|

|

Material Of Cutting

|

CR12Mov with quench treatment

|

|

Electronic control

|

PLC control with touch screen

|

|

Weight

|

About 7 tons

|

One-Stop Global Service

We provide comprehensive global service solutions, including:

Pre-sales consulting: Multilingual technical support (English, Portuguese, Russian, etc.), on-demand production line planning, and personalized equipment configuration proposals.

Sales support: Professional handling of customs clearance, international shipping, and on-site installation, paired with systematic technical training for operators and maintenance personnel.

After-sales service: 24/7 online technical assistance, 24-month warranty for core components, lifetime maintenance guidance, and free technical upgrade services for 3 years.

Certifications

CE | ISO9001 | SGS | TUV | ANSI

Typical Applications

Supermarket and hypermarket shelves panel production

Warehouse storage rack layer panel manufacturing

Convenience store and pharmacy shelf panel production

Cold chain and food logistics rack panels