Xinnuo High Efficiency Customizable Racking Beam Roll Form Machine: Empower Your Storage Production

In the dynamic landscape of modern warehousing, racking beams serve as the critical load-bearing link between uprights, demanding both exceptional strength and flexible design—and Xinnuo’s High Efficiency Customizable Racking Beam Roll Form Machine is engineered to deliver exactly that. As a flagship innovation from Hebei Xinnuo, a brand with 25+ years of roll forming expertise and ISO 9001 certification, this machine redefines what manufacturers can achieve in racking beam production, catering to clients across 60+ countries, from the high-volume e-commerce fulfillment centers of the U.S. to the precision-focused industrial warehouses of Germany.

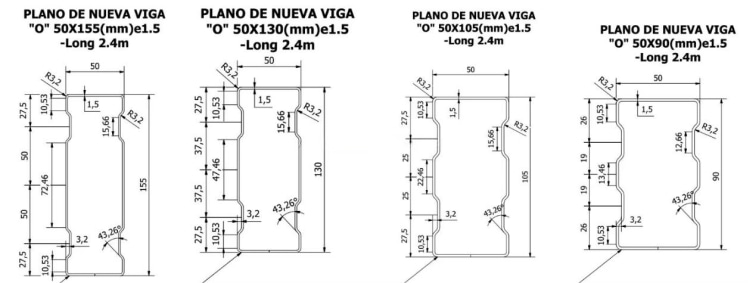

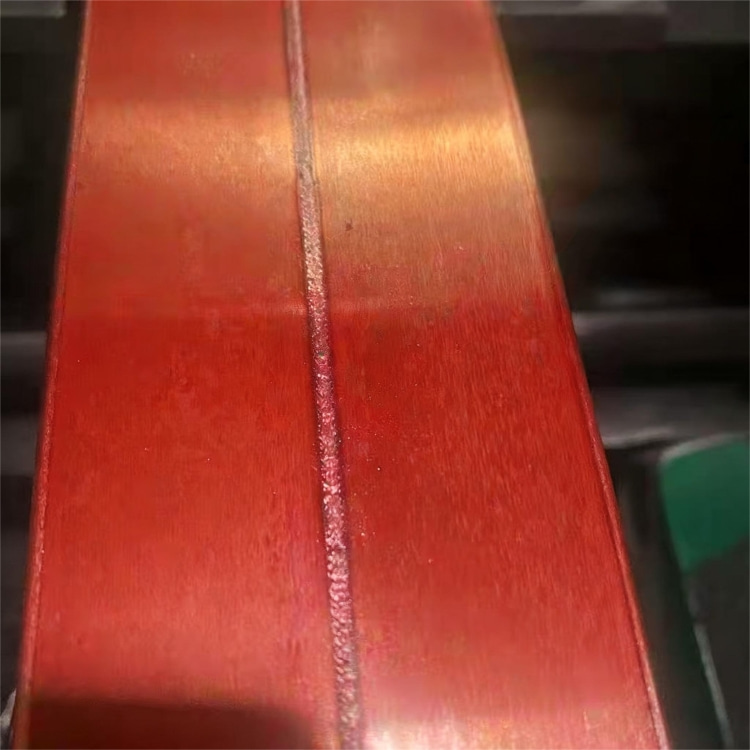

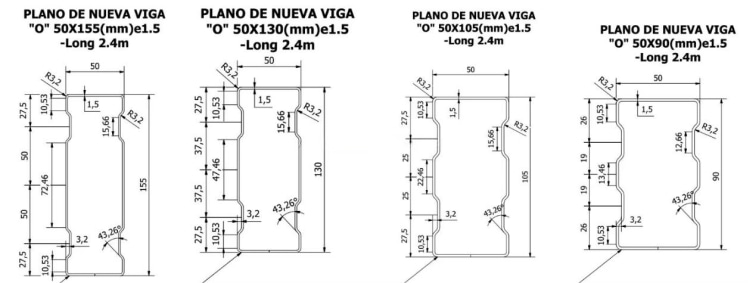

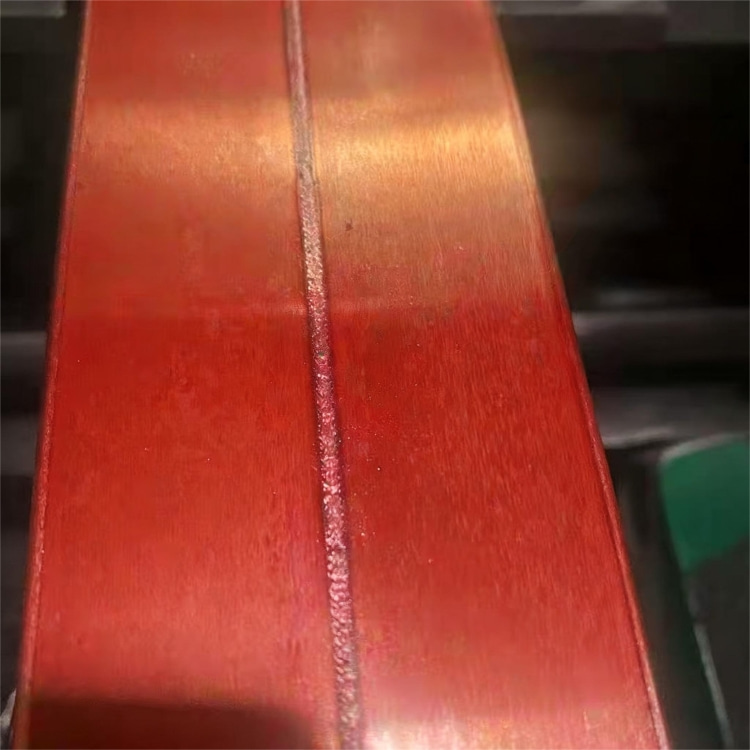

What sets this machine apart is its seamless integration of “high efficiency” and “customization”—two core demands of today’s storage equipment manufacturers. Unlike rigid, one-size-fits-all machines that limit production flexibility, Xinnuo’s solution adapts to diverse needs while maximizing output. It processes 1.0-3.2mm thick materials, including galvanized steel, carbon steel, and colored steel coils, transforming them into high-quality racking beams with consistent profiles. Whether clients need light-duty beams for retail shelving or heavy-duty ones for industrial pallet racks, the machine’s adaptable design ensures smooth production without costly retooling delays.

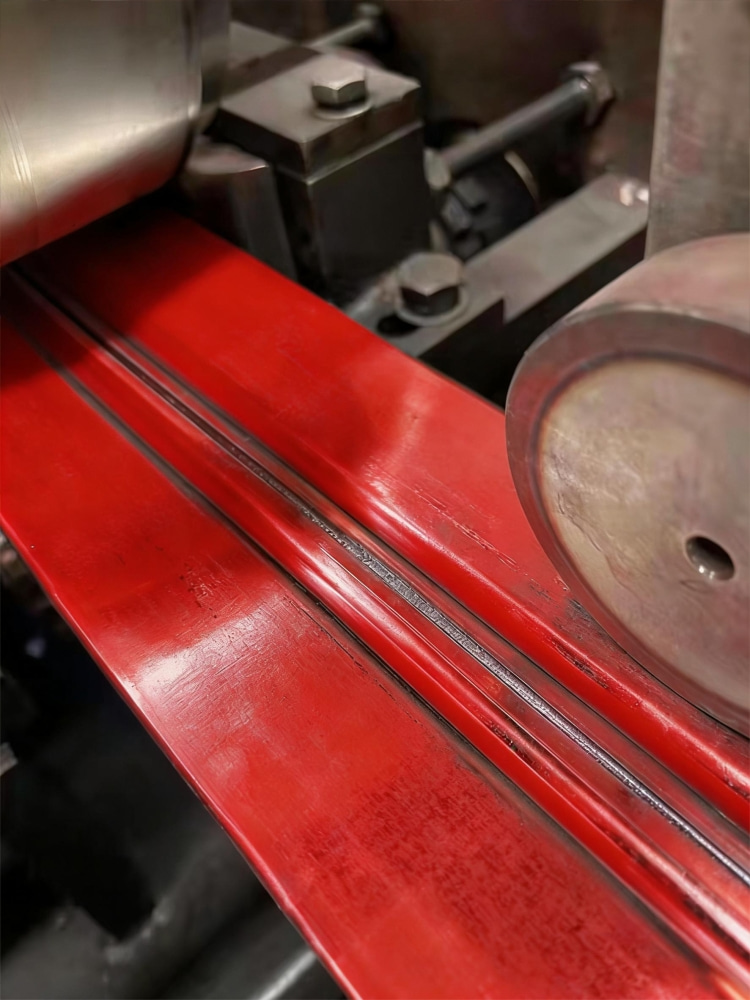

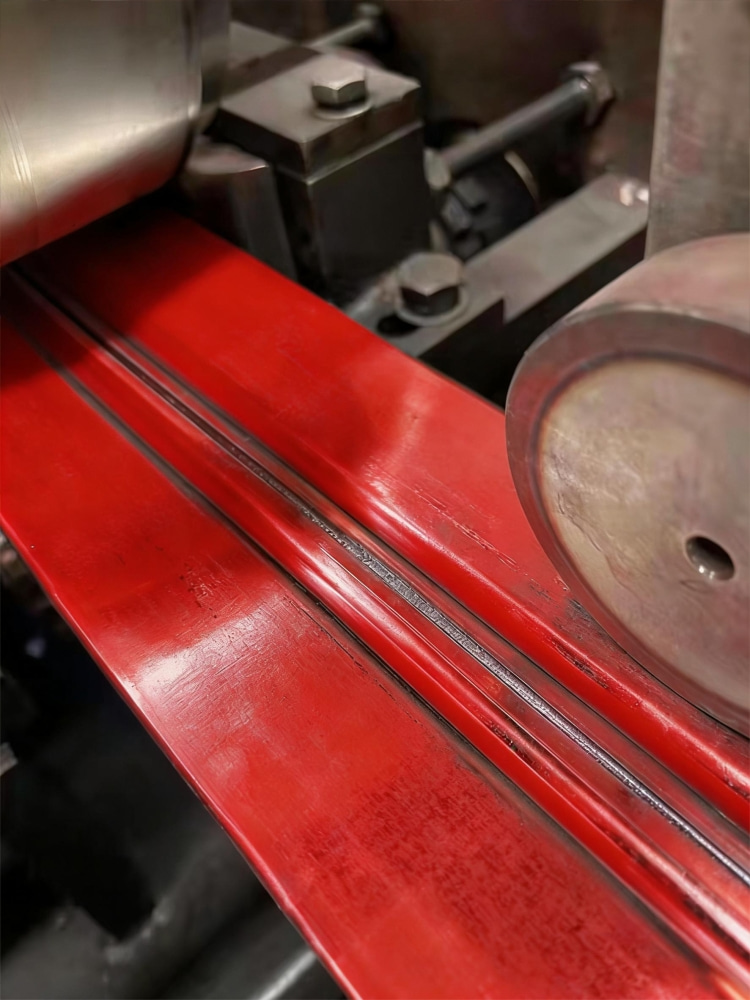

Efficiency is embedded in every component, addressing the labor and time pressures plaguing the industry. Equipped with a Siemens PLC control system and a 7-inch touchscreen HMI, the machine automates the entire production workflow: from a 5-ton hydraulic decoiler that feeds materials stably, to a precision leveling unit that eliminates coil warpage, a high-speed punching system for beam connection holes, and a servo-driven flying cutting device that trims beams to exact lengths (1-6m) without stopping production. This fully automated process slashes labor requirements from 3 workers to 1, reduces labor costs by 70%, and boosts production speed to 12-18 meters per minute—far outpacing semi-automatic alternatives. Clients report a 50% increase in daily output within the first month of adoption, a game-changer for meeting tight order deadlines.

Customization is where the machine truly shines, tailored to the unique needs of each manufacturer. Xinnuo’s R&D team of 50+ engineers works closely with clients to design roller configurations, punching patterns, and beam profiles that align with their specific product lines. Whether it’s a U-section beam for adjustable shelving, a Z-section beam for heavy-duty storage, or a custom profile with unique mounting features, the machine can be programmed to produce 100+ different designs with minimal setup time (under 5 minutes). This flexibility allows manufacturers to cater to niche markets, from cold-chain warehouses requiring corrosion-resistant beams to automotive facilities needing beams that bear heavy parts.

Durability and global compliance ensure long-term value and market access. The machine features a 6.5-ton reinforced welded steel frame with anti-vibration pads, supporting 24/7 continuous operation without compromising stability. Its 24 hardened GCR15 steel rollers (58HRC hardness) with chrome plating resist wear, extending service life by 40% compared to standard rollers. Additionally, it holds CE, TUV, and ANSI certifications, complying with strict safety and quality standards in the EU, North America, and Southeast Asia—removing barriers for manufacturers targeting global markets.

Beyond the machine itself, Xinnuo’s comprehensive support ecosystem turns equipment into a strategic asset. Clients receive free on-site installation, personalized operator training, 24/7 technical support (via remote troubleshooting and on-site service), a 1-year standard warranty (extendable to 3 years), and lifetime access to genuine spare parts. This end-to-end service ensures minimal downtime: 95% of technical issues are resolved within 4 hours, keeping production lines running smoothly. The machine’s tangible benefits—40% higher efficiency, 6% lower material waste, and ROI within 8-12 months—have made it a trusted choice for both small-scale manufacturers and large industrial players.

As the demand for intelligent, space-saving storage systems grows, Xinnuo remains committed to innovating. We invest 15% of annual revenue in R&D, focusing on AI-integrated control systems that predict maintenance needs and IoT-enabled monitoring for real-time production tracking. For manufacturers seeking to stay ahead in the competitive storage industry, Xinnuo’s High Efficiency Customizable Racking Beam Roll Form Machine is more than equipment—it’s a partner that enhances product quality, expands market reach, and drives sustainable growth.