Product Overview

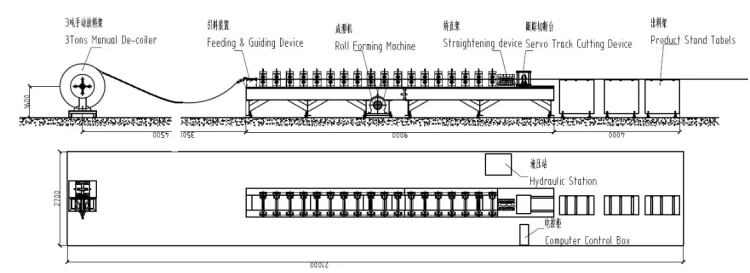

The Metal Shelf Storage Rack Beam Machine is a professional and customizable production solution for high-strength metal shelf beams. Designed for the global storage equipment manufacturing industry, it integrates multiple advanced processes to realize the automatic production of shelf beams with different specifications. The machine adopts high-quality core components and scientific structural design, ensuring stable operation, long service life, and high product qualification rate. It can flexibly adapt to various raw material types and profile requirements, providing strong support for manufacturers to expand product lines and meet diverse market demands.

Core Technical Specifications

-

Raw material: Cold-rolled steel, Galvanized steel (optional stainless / color-coated steel)

-

Material thickness: 1.5 – 3.0 mm

-

Roller material: GCr15 (or optional Cr12) alloy steel, heat treated (quenched / hardened)

-

Roller hardness: HRC 58 – 62° (depending on heat treatment)

-

Number of forming stations: 16 – 28 stations (profile dependent)

-

Forming (line) speed: 5 – 15 m/min (depending on profile & configuration)

-

Main motor power: 15 – 22 kW (depending on model)

-

Cutting / Shearing system:Hydraulic cutting (or saw-cut); cutting blades made of heat-treated Cr12 / Cr12MoV

-

Control system: PLC control (Siemens / Panasonic / Delta optional) — supports automatic forming, punching, cutting, length & quantity control

-

Decoiler: Manual or hydraulic decoiler (capacity configurable, e.g. 3t–5t)

-

Material width: As per customer’s profile drawing / specification

-

Profile types: Upright rack columns / shelf upright posts / pallet rack uprights / warehouse shelving uprights

-

Power supply / Voltage: 380 V, 50 Hz, three-phase (customizable per customer requirement)

Key Product Advantages

1. Strong Customization Capability: Supports customization of material width, profile type, power supply, and other parameters according to customer drawings and requirements. Multiple configurable options (roller material, cutting system, PLC brand) enable the machine to adapt to different production scenarios and product needs.

2. Durable & Reliable: Core components such as rollers, cutting blades, and main motors are made of high-quality materials and undergo strict heat treatment, ensuring excellent wear resistance and stability. The machine can operate continuously for a long time with a low failure rate, reducing maintenance costs for customers.

3. Energy-Saving & Environmental Protection: The optimized main motor and transmission system effectively reduce energy consumption during operation. The closed production process reduces noise and waste, complying with global environmental protection requirements and helping customers achieve green production.

Quality & Safety Assurance

The machine strictly implements international quality control standards, from raw material procurement to finished product delivery, every link is subject to rigorous inspection. It has passed SGS and TUV Rheinland certifications, ensuring product quality and safety performance. The safety protection system is fully equipped to provide a safe working environment for operators.

Global Service Support

We provide multilingual technical support (English, German, Russian, etc.), on-site installation and commissioning, operator training, and long-term after-sales maintenance services. The professional after-sales team responds quickly to solve customer problems in a timely manner, ensuring the continuous and stable operation of the equipment.

Typical Applications

Suitable for the production of shelf beams for heavy-duty industrial racks, pallet racks, warehouse shelving, and commercial storage racks, widely used in manufacturing, logistics, retail, cold-chain and other industries.