Xinnuo Pallet Racking Roll Forming Machine: Precision Cold-Forming for Sturdy Shelf Uprights

Pallet racking systems are the backbone of modern warehouses, and their performance hinges entirely on the quality of shelf uprights—the vertical pillars that bear the weight of heavy pallets and ensure structural stability. Xinnuo’s Pallet Racking Roll Forming Machine is a specialized cold-forming solution engineered to produce these critical components, merging 25+ years of roll forming expertise with cutting-edge technology to serve manufacturers across 65+ countries. As an ISO 9001, CE, and TUV-certified brand, Hebei Xinnuo has become a trusted name in the global storage equipment industry, powering the production of reliable pallet racks for e-commerce fulfillment centers, automotive parts warehouses, and industrial logistics hubs from Europe to Southeast Asia.

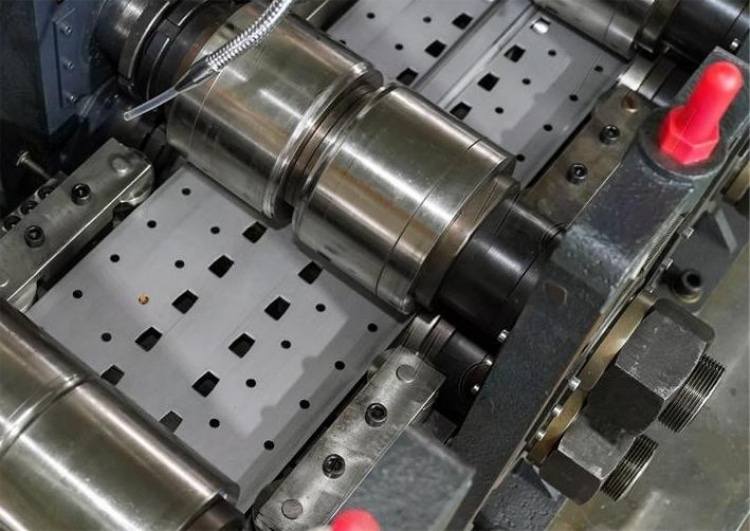

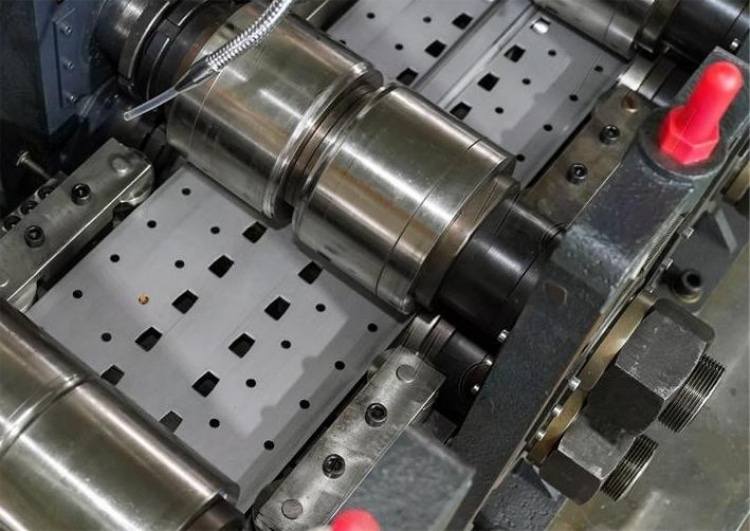

What sets this machine apart is its unwavering focus on the unique demands of pallet rack upright production. Unlike standard forming equipment, cold-forming for shelf uprights requires exceptional precision to maintain consistent wall thickness, uniform profiles, and accurate hole positioning—all essential for withstanding dynamic loads and ensuring seamless assembly with beams. Xinnuo’s machine excels here by processing 1.2-3.5mm thick high-tensile materials, including galvanized steel, carbon steel, and weather-resistant steel coils. The cold-forming process preserves the material’s inherent strength, eliminating heat-induced deformation and ensuring that each upright can bear loads of 1000-8000kg stably. Every finished upright boasts dimensional tolerance of ±0.2mm, smooth edges free of burrs, and perfectly aligned mounting holes—critical for reducing assembly time and preventing structural weaknesses in the final rack system.

Efficiency is a defining feature of this machine, addressing the production bottlenecks that hinder manufacturers’ scalability. Equipped with a Siemens PLC control system and a 10-inch color touchscreen HMI, it automates the entire cold-forming workflow from material feeding to finished product output. A 6-ton hydraulic decoiler with automatic centering and tension control feeds coils stably, minimizing waste caused by misalignment. A multi-roller precision leveling unit eliminates coil warpage, ensuring flat blanks for consistent forming. The high-speed hydraulic punching module, capable of 35 punches per minute, creates precise mounting holes of various sizes, while the 26-group hardened roller forming system shapes the material in one seamless pass—avoiding the inconsistencies of multi-step processes. The servo-driven flying cutting device trims uprights to exact lengths (1-12m) without stopping production, boosting output to 12-20 meters per minute. This full automation reduces labor needs from 3 workers to 1, cuts labor costs by 70%, and enables manufacturers to meet large orders with lead times shortened by 40%.

As the global demand for intelligent warehousing grows, Xinnuo continues to innovate. We invest 15% of annual revenue in R&D, integrating AI predictive maintenance and IoT real-time monitoring into our machines. This allows clients to remotely track production metrics, predict component failures, and optimize workflows—embracing Industry 4.0. For manufacturers seeking to enhance competitiveness, Xinnuo’s Pallet Racking Roll Forming Machine is more than equipment; it’s a strategic asset that elevates product quality, streamlines operations, and drives growth. Choose Xinnuo, and let our cold-forming expertise power your success in the global storage equipment market.