| Warehouse Shelf Upright Roll Forming Machine | |

|---|---|

| Machinable Material | A) Galvanized Steel B) Stainless Steel Thickness (MM): 1.5–3.0 as per customer |

| Yield Strength | 250 – 550 MPa |

| Tensile Stress | G250 MPa – G550 MPa |

| Decoiler | Manual Decoiler * Hydraulic Decoiler (Optional) |

| Punching System | Hydraulic Punching Station * Punching Press (Optional) |

| Forming Station | About 25 Stands * According To Your Profile Drawings |

| Driving System | Chain Drive * Gearbox Drive (Optional) |

| Machine Structure | Wall Panel Station * Cast Iron Stands (Optional) |

| Forming Speed | 5–15 m/min * Or According To Your Profile Drawings |

| Rollers’ Material | GCr15 * Cr12 (Optional) |

| Cutting System</ | |

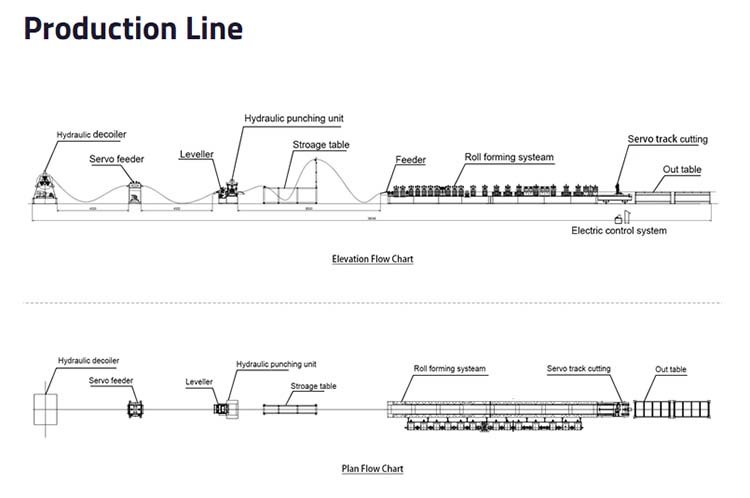

Our Warehouse Shelf Upright Roll Forming Machine, also known as a Pallet Racking Roll Forming Machine, is engineered to produce upright frames / upright racks with material thickness from 1.5–3.0 mm. The entire process — uncoiling, servo feeding, punching, roll forming, and cutting — is automated on one line.

In addition, we offer roll forming machines for box beam, step beam (P-beam), and shelf panels — all of which are essential components of a complete pallet racking system.

Pallet racking provides a cost-effective solution for storing palletized goods. Made up of separate frames and beams in a wide variety of sizes, and secured with locking pins, it can be flexibly configured based on pallet size or forklift type.

We develop customized solutions according to your drawings, tolerance requirements, and budget. Whether you need the Box Beam Roll Forming Machine, the Step Beam Roll Forming Machine, or the Shelf-Panel Roll Forming Machine, our one-to-one service ensures each production line is tailored to your needs.

With our Rack Roll Forming Machine, Upright Roll Forming Machine, and all supporting equipment, the quality of your pallet racking profiles is guaranteed. At SUNWAY (or your company name), we deliver reliable, high-precision roll forming solutions built for your warehouse system.

| Warehouse Shelf Upright Roll Forming Machine | |

|---|---|

| Machinable Material | A) Galvanized Steel B) Stainless Steel Thickness (MM): 1.5–3.0 as per customer |

| Yield Strength | 250 – 550 MPa |

| Tensile Stress | G250 MPa – G550 MPa |

| Decoiler | Manual Decoiler * Hydraulic Decoiler (Optional) |

| Punching System | Hydraulic Punching Station * Punching Press (Optional) |

| Forming Station | About 25 Stands * According To Your Profile Drawings |

| Driving System | Chain Drive * Gearbox Drive (Optional) |

| Machine Structure | Wall Panel Station * Cast Iron Stands (Optional) |

| Forming Speed | 5–15 m/min * Or According To Your Profile Drawings |

| Rollers’ Material | GCr15 * Cr12 (Optional) |

| Cutting System | Hydraulic Cutting * Saw Cutting (Optional) |

| Frequency Changer Brand | Yaskawa * Siemens (Optional) |

| PLC Brand | Panasonic * Siemens (Optional) |

| Power Supply | 380V 50Hz 3-phase * Or According To Your Requirement |

| Machine Color | Industrial Blue * Or According To Your Requirement |