In the fast-paced world of modern logistics and warehousing, teardrop pallet racks have become the gold standard for their quick assembly, superior stability, and space-saving design—and Xinnuo’s Teardrop Pallet Rack Roll Forming Machine is the ultimate tool for manufacturing these high-demand storage solutions. As a leading innovation from Hebei Xinnuo, a brand with 25+ years of expertise in roll forming technology and ISO 9001 certification, this machine empowers manufacturers to meet the soaring global demand for efficient storage systems, serving clients across 50+ countries, from North America’s bustling distribution centers to Asia’s industrial hubs.

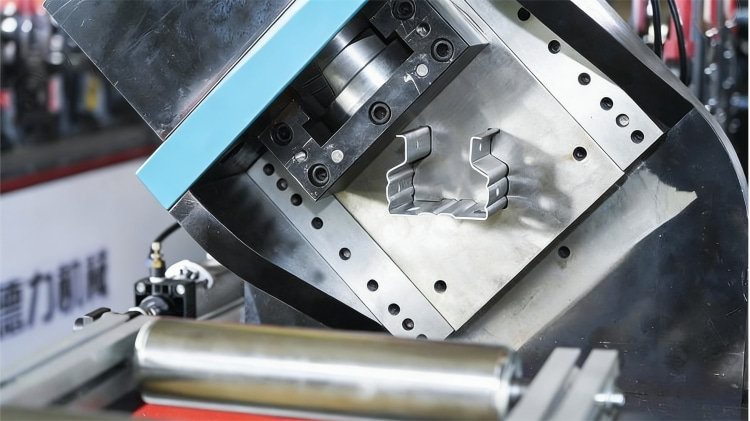

What sets this machine apart is its precision-engineered focus on teardrop-style profiles—the defining feature of modern pallet racks. Unlike traditional rack systems that require bolts or tools for assembly, teardrop racks use a snap-in design, where beams lock seamlessly into teardrop-shaped holes on uprights. Xinnuo’s machine masters this critical detail, processing 1.0-3.2mm thick galvanized steel, carbon steel, or cold-rolled steel coils into uprights with perfectly formed teardrop holes, ensuring consistent hole spacing and dimensional accuracy of ±0.2mm. This precision eliminates assembly delays, reduces errors, and guarantees the structural integrity of racks that bear heavy loads (up to 6,000kg per upright) in warehouses storing pallets, industrial parts, and consumer goods.

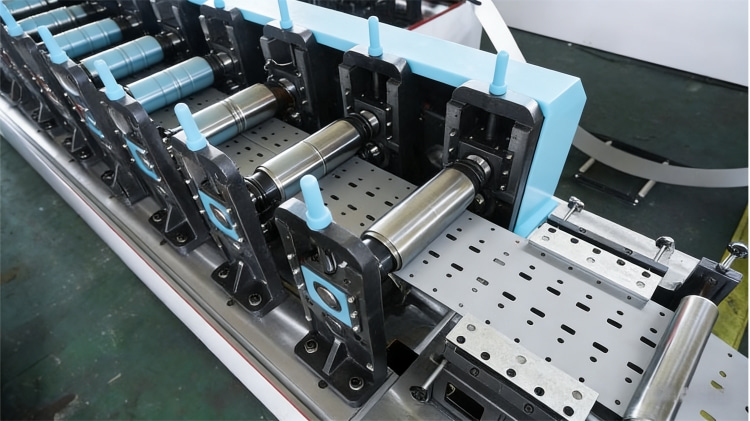

Automation lies at the heart of its exceptional performance, addressing the labor shortages and cost pressures plaguing the manufacturing industry. Equipped with a Siemens PLC control system and a 7-inch touchscreen HMI, the machine allows operators to preprogram 100+ custom profiles—from standard teardrop uprights for medium-duty shelving to reinforced designs for heavy-duty industrial use. The fully integrated workflow streamlines production: a 5-ton hydraulic decoiler feeds materials smoothly, a precision leveling unit eliminates coil warpage, a high-speed hydraulic punching system creates teardrop holes with pinpoint accuracy, and a servo-driven flying cutting device trims uprights to exact lengths (1-8m) without interrupting production. This seamless automation cuts labor requirements from 3 workers to 1, slashes labor costs by 70%, and boosts production speed to 12-18 meters per minute—far outpacing manual or semi-automatic alternatives.

Durability and reliability are built into every component, designed to withstand the rigors of 24/7 industrial operation. The machine features a 7-ton reinforced welded steel frame with anti-vibration pads, ensuring stability even during high-speed production. Its 24 hardened GCR15 steel rollers (58HRC hardness) with chrome plating resist wear and tear, extending service life by 40% compared to standard rollers. Additionally, the machine holds CE, TUV, and ISO certifications, complying with strict global safety and quality standards—critical for manufacturers exporting to EU, American, and Southeast Asian markets.

Beyond the equipment itself, Xinnuo’s comprehensive support ecosystem delivers long-term value. Customers benefit from 24/7 technical assistance, including remote troubleshooting and on-site service for installation and maintenance. The package includes free operator training, a 1-year standard warranty (extendable to 3 years), and lifetime access to high-quality spare parts. These perks translate to tangible business results: clients report a 50% increase in production output, a 6% reduction in material waste, and a return on investment within 9-12 months.

Whether you’re a small-scale shelving manufacturer or a large industrial storage solution provider, Xinnuo’s Teardrop Pallet Rack Roll Forming Machine adapts to your needs. It’s not just a piece of equipment—it’s a strategic partner that enhances product quality, streamlines operations, and gives you a competitive edge in the global storage market. For businesses committed to delivering efficient, durable, and easy-to-assemble pallet racks, this machine is the definitive choice to drive growth and success.