| Parameter | Value |

|---|---|

| Type of material to be processed | CR / HR |

| Yield strength | 400 MPA (Max.) |

| Length of profile sheet | No limit |

| Total connected power required | 45 KW |

| Coil Width range | 150 mm to 300 mm |

| Coil Thickness range | 0.8 mm to 2.00mm |

| Coil weight (Allowed on Decoiler) | 3 Ton |

| Production line speed (Without Cutting) | 0 to 8 MPM |

| Production line speed (With Punching & Cutting) | Approx production line speed with Cutting and punching is 4 mtr/min to 5 mtr/min depending on your final length and number’s of punching. Above calculation is calculated on the basis of 3 meter production length |

| Automation level in performance | P.L.C. controlled length |

| Accuracy level | length: ±2 M.M. |

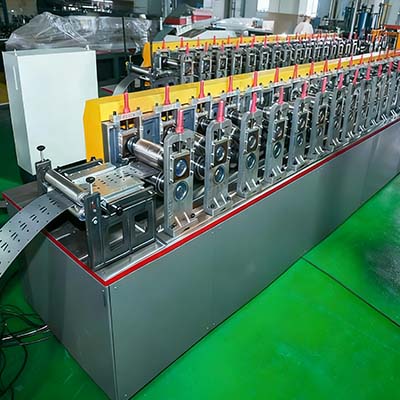

Product Overview

Our Heavy-Duty Shelf Column Roll Forming Machine is engineered for high-strength applications. It’s widely used to manufacture city shelves, industrial storage racks, super-heavy shelves, and other cold-rolled profiles. With automation driven by industrial PLC and a human-machine interface, you simply input parameters such as hole spacing, product length, and quantity — and the machine handles punching, forming, and cutting in a single, continuous flow.

Key Features

Fully automatic production: punching, molding, and cutting all in one automated process

Continuous operation without shutdown, ensuring stable product quality and consistent dimensions

High production efficiency and reduced labor cost, improving your competitiveness in the market

Applications

Ideal for manufacturing:

Heavy-duty shelf columns for warehouse and industrial rack systems

Super-heavy load storage shelving

City shelving structures or other large-scale shelving profiles

| Parameter | Value |

|---|---|

| Type of material to be processed | CR / HR |

| Yield strength | 400 MPA (Max.) |

| Length of profile sheet | No limit |

| Total connected power required | 45 KW |

| Coil Width range | 150 mm to 300 mm |

| Coil Thickness range | 0.8 mm to 2.00mm |

| Coil weight (Allowed on Decoiler) | 3 Ton |

| Production line speed (Without Cutting) | 0 to 8 MPM |

| Production line speed (With Punching & Cutting) | Approx production line speed with Cutting and punching is 4 mtr/min to 5 mtr/min depending on your final length and number’s of punching. Above calculation is calculated on the basis of 3 meter production length |

| Automation level in performance | P.L.C. controlled length |

| Accuracy level | length: ±2 M.M. |

Benefits

Production cost reduction: automating key processes lowers labor and material waste

Efficiency boost: continuous, automated output improves throughput

Flexibility: supports multiple production needs, allowing companies to adapt to changing market demands

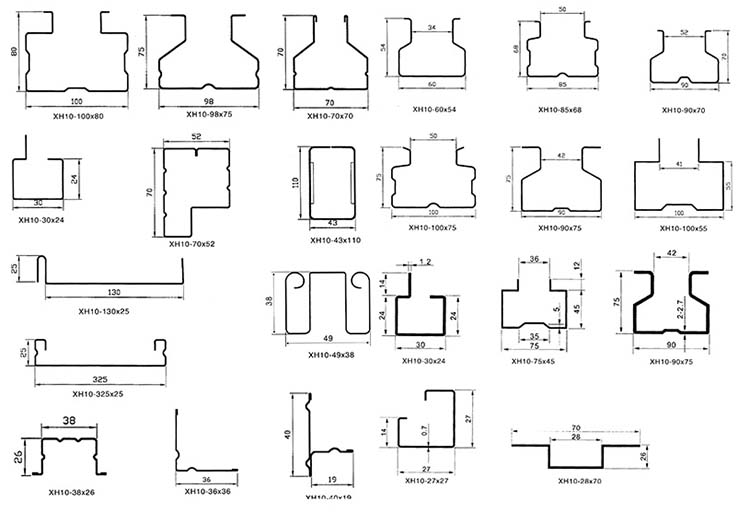

Customization & Service

Tell us your drawing (hole pattern, length, thickness) and budget — we will design a one-on-one solution that matches your exact shelf-column requirements. With our heavy plate rolling machines, you can scale up production without compromising quality or efficiency.