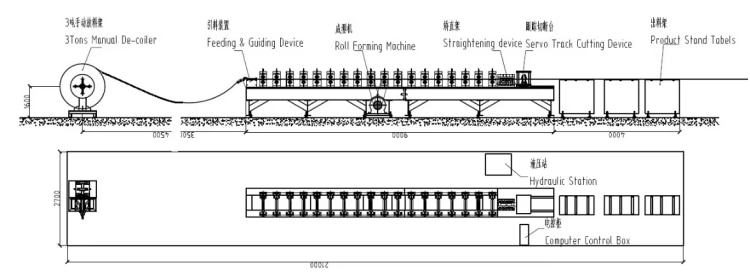

Rack Partition Beam Roll Forming Machine

Product Overview

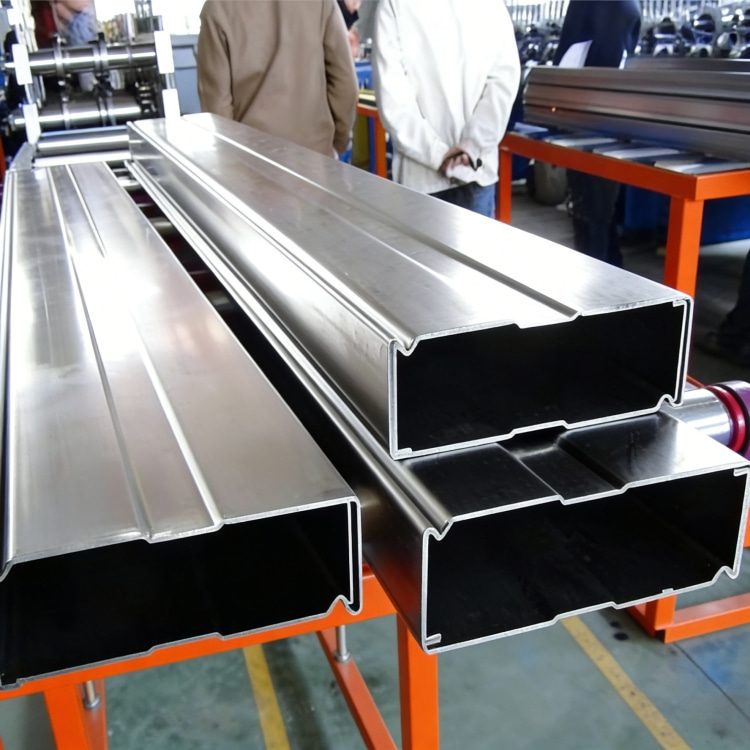

The Rack Partition Beam Roll Forming Machine is a professional automated production equipment tailored for manufacturing high-precision rack partition beam components. As an essential part of storage rack systems, partition beams play a vital role in realizing layered storage and improving space utilization. This machine integrates advanced forming technology, stable transmission systems, and intelligent control modules, ensuring efficient, consistent, and high-quality production of rack partition beams. It has been widely recognized by rack manufacturers worldwide for its reliable performance, strong adaptability, and easy operation.

Core Technical Specifications

-

Suitable Plate Material: thickness 1.2-1.5mm, Galvanized steel or blank steel, compatible with mainstream rack partition beam raw materials

-

Working Speed: about 8-12 meters / min, balancing high production efficiency and forming precision

-

Forming Steps: about 12 stations, ensuring uniform stress distribution during forming, resulting in smooth surfaces and precise dimensions of finished partition beams

-

Material of Roller: Gcr15, Quench HRC58-62 Plated Chrome, featuring excellent wear resistance and deformation resistance, extending equipment service life

-

Material of Shaft: 45# Advanced Steel (Diameter: 76mm), thermal refining, providing strong load-bearing capacity and stable transmission performance

-

Driven system: Chain drive, ensuring stable power transmission, low operating noise, and reliable long-term operation

-

Main Power with reducer: 5.5KW WH Chinese Famous, delivering sufficient and stable power for continuous production

-

Cutting: hydraulic cutting, ensuring smooth cutting surfaces, high length precision, and no burrs on finished products

-

Control System: The whole machine is controlled by PLC, equipped with Siemens PLC (Japan) supporting English and Chinese Language, realizing intelligent operation and real-time production monitoring

-

Encoder: Omron (Japan), ensuring accurate control of forming position and working speed

-

Electric parts: Schneider, guaranteeing the safety, stability, and long service life of the electrical system

Global One-Stop Service

Pre-sales Consulting

We provide multilingual technical support (English, German, Russian, Spanish, Arabic), on-site factory layout planning, and customized production solutions according to customers' specific product specifications, material characteristics, and production scales.

Sales Support

Professional packaging is adopted for the equipment to prevent damage during transportation. We provide complete industrial equipment customs clearance documents and arrange professional engineers to conduct on-site installation, commissioning, and debugging. Systematic training on equipment operation, maintenance, and quality control is provided for customer teams to ensure proficient use.

After-sales Service

24/7 online technical assistance is available to solve customers' problems in a timely manner. On-site maintenance support is provided within 48 hours in key regions. We offer a long-term warranty for core components of the equipment, provide lifelong maintenance guidance and free software upgrade services, ensuring the continuous and stable operation of the equipment.

Certifications

CE | ISO9001:2015 | SGS | TUV Rheinland

Typical Applications

-

Production of rack partition beams for commercial retail shelves

-

Manufacturing of partition beams for industrial warehouse storage racks

-

Customized production of partition beams for office and household storage shelves

-

Production of partition beams for intelligent logistics distribution center storage systems