Product Overview

The Upright Racking Roll Forming Line is a green and intelligent production equipment tailored for upright rack columns. Focusing on energy conservation and environmental protection, it adopts optimized motor and transmission systems to reduce energy consumption, while the closed production process minimizes noise and waste emissions. Equipped with intelligent monitoring and data analysis functions, it helps manufacturers realize lean production and is favored by environmentally conscious enterprises worldwide.

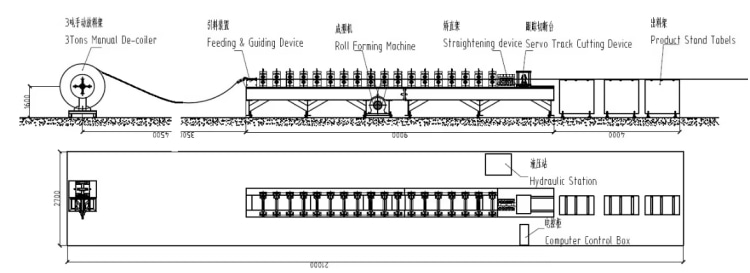

Core Technical Specifications

-

Raw material: Cold-rolled steel, Galvanized steel (optional stainless / color-coated steel)

-

Material thickness: 1.5 – 3.0 mm

-

Roller material: GCr15 (or optional Cr12) alloy steel, heat treated (quenched / hardened)

-

Roller hardness: HRC 58 – 62° (depending on heat treatment)

-

Number of forming stations: 16 – 28 stations (profile dependent)

-

Forming (line) speed: 5 – 15 m/min (depending on profile & configuration)

-

Main motor power:15 – 22 kW (depending on model)

-

Cutting / Shearing system: Hydraulic cutting (or saw-cut); cutting blades made of heat-treated Cr12 / Cr12MoV

-

Control system: PLC control (Siemens / Panasonic / Delta optional) — supports automatic forming, punching, cutting, length & quantity control

-

Decoiler: Manual or hydraulic decoiler (capacity configurable, e.g. 3t–5t)

-

Material width: As per customer’s profile drawing / specification

-

Profile types: Upright rack columns / shelf upright posts / pallet rack uprights / warehouse shelving uprights

-

Power supply / Voltage: 380 V, 50 Hz, three-phase (customizable per customer requirement)

Key Product Advantages

1. Energy-Saving & Environmental Protection: The optimized main motor and transmission system reduce energy consumption by 15% compared to traditional equipment. The closed production process reduces noise and waste emissions, complying with global environmental standards such as RoHS and REACH.

2. Intelligent Lean Production: The PLC control system is equipped with intelligent data monitoring and analysis functions, which can track production progress and quality in real time, helping manufacturers optimize production processes and realize lean management.

3. Wide Global Adaptability: Compatible with multiple raw material types and customizable power supply standards, the line can adapt to diverse regional production conditions worldwide, facilitating manufacturers' global market expansion.

Quality & Safety Assurance

The line strictly implements international environmental protection and quality control standards, with complete quality inspection and environmental protection testing procedures. It has obtained relevant environmental protection certifications and CE, ISO9001:2015 certifications, ensuring green and high-quality production.

Global Service Support

We provide customized green production solutions, pre-sales environmental protection standard consultation, on-site installation and commissioning, operator training on energy-saving operation, and 24/7 after-sales technical support, escorting customers' green production and global market development.

Typical Applications

Widely used in the production of environmentally friendly upright rack columns for green industrial parks, eco-logistics centers, high-end commercial facilities, and food cold-chain storage racks, meeting environmental protection and quality requirements of global markets.