Xinnuo High Quality Rack Upright Roll Forming Machine: The Epitome of Precision & Durability

Xinnuo’s High Quality Rack Upright Roll Forming Machine is more than just production equipment—it’s a strategic asset for manufacturers in the global storage industry. Backed by Hebei Xinnuo’s 25+ years of roll forming expertise and ISO 9001 certification, this machine redefines what “high quality” means for heavy-duty rack upright production, catering to warehouses, logistics hubs, and industrial storage facilities across 50+ countries, from Germany’s automotive centers to Australia’s distribution networks.

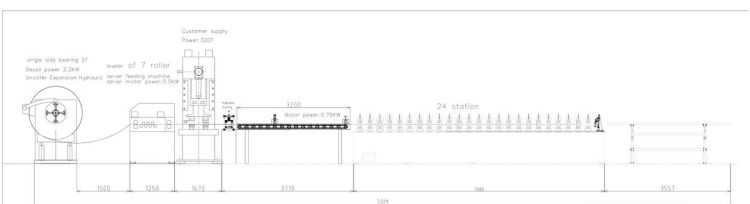

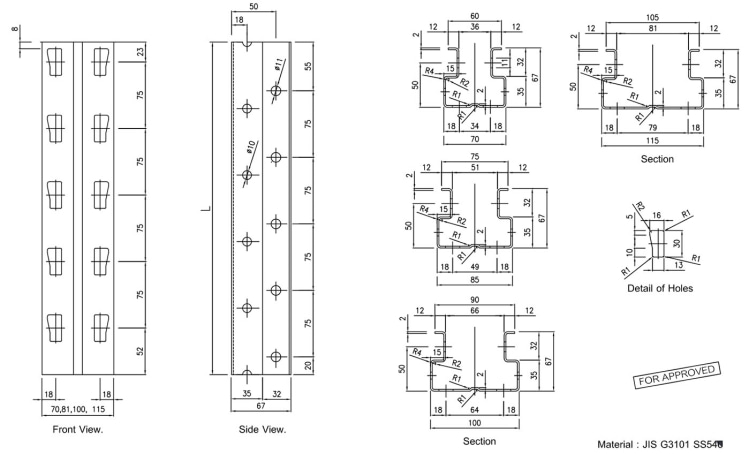

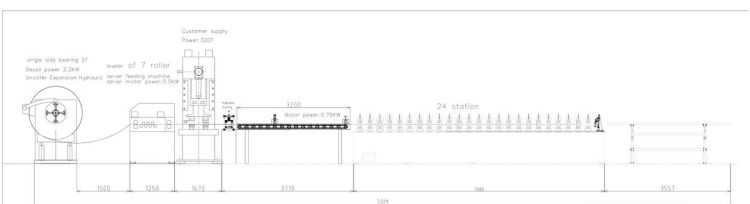

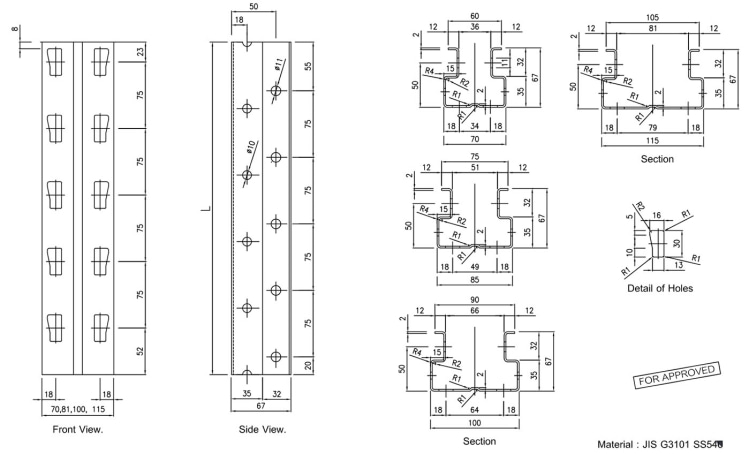

At its core, the machine is engineered to deliver uncompromising precision. It processes 0.8-3.0mm thick high-tensile materials, including galvanized steel, carbon steel, and stainless steel coils (width 300-600mm), transforming them into uniform uprights via 22 hardened GCR15 steel rollers. These chrome-plated rollers (52HRC hardness) ensure scratch-free forming while maintaining a dimensional tolerance of ±0.3mm—critical for seamless rack assembly and structural stability under loads up to 5,000kg per upright. A 22kW high-efficiency motor drives production at 10-15m/min, balancing speed with the meticulous quality control that Xinnuo is renowned for.

Intelligence and automation are woven into every component. Equipped with a Siemens PLC control system and a 7-inch touchscreen HMI, operators can preprogram 100+ custom profiles (C-section, U-section, and specialized designs), monitor real-time data (production speed, output volume, error alerts), and switch between specifications in just 5 minutes—no advanced technical skills required. The fully integrated workflow includes a 5-ton hydraulic decoiler (with automatic coil centering), precision leveling unit (to eliminate material warpage), high-speed hydraulic punching (for beam connection holes with ±0.1mm accuracy), roll forming, and servo-driven flying cutting, reducing labor needs from 3 workers to 1 and cutting labor costs by 65%.

Durability is non-negotiable. The machine features a 6.5-ton reinforced welded steel frame (7.5×1.0×1.5m) fitted with anti-vibration pads, enabling 24/7 continuous operation without compromising stability. Wear-resistant components and a centralized lubrication system extend its service life by 30% compared to standard models, while CE, TUV, and ISO certifications guarantee compliance with strict EU and American industrial standards. This combination of robustness and compliance has made it a top choice for buyers in the UAE, Netherlands, and Southeast Asia.

Beyond the machine itself, Xinnuo’s support ecosystem adds unparalleled value. Customers benefit from 24/7 technical assistance (remote troubleshooting and on-site service), free on-site installation, a 1-year standard warranty (extendable to 3 years), and lifetime after-sales guidance. The result? A 40% increase in production output, 5% lower material waste, and a fast ROI of 10-12 months. For businesses that refuse to compromise on quality while scaling their storage component manufacturing, Xinnuo’s High Quality Rack Upright Roll Forming Machine is the definitive solution.