Product Overview

As a flexible customized solution, this machine adapts to diverse C-type shelf upright production needs. It offers multiple optional configurations for decoilers, driving systems, rollers and frequency changers, perfectly fitting personalized production requirements of global customers.

Core Technical Specifications

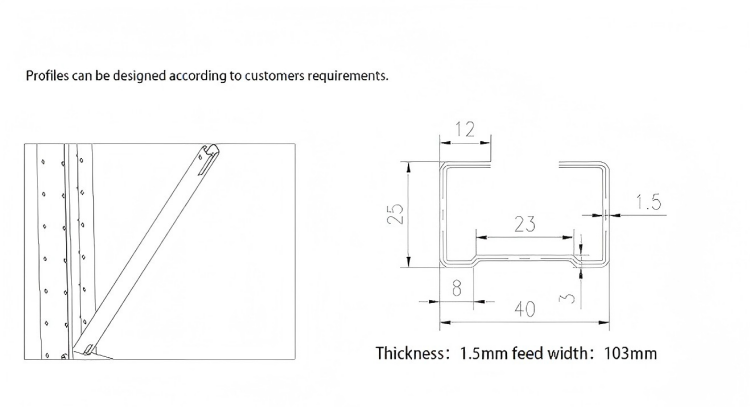

Machinable Material: Galvanized Coil, PPGI, PPGL, Cold-rolled Steel, Carbon Steel (Thickness: 1.5-1.8 mm as per customer)

Yield Strength: 250 - 350 Mpa; Tensil Stress: 350 Mpa-500 Mpa

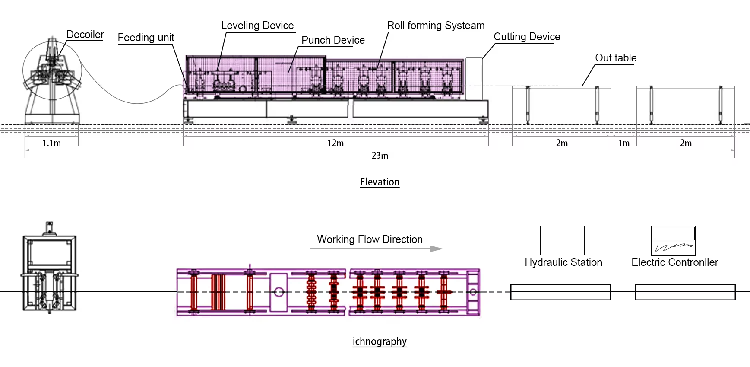

Nominal Forming Speed: 10-15 m/min (or according to requirement); Forming Station: About 14 (according to profile drawings)

Decoiler: Manual Decoiler (Hydraulic Decoiler optional); Driving System: Chain Drive (Gearbox Drive optional)

Machine Structure: Steel Plates Welded (Cast Iron Stands optional); Rollers’ Material: GCr 15 (Cr12Mov optional)

Cutting System:Hydraulic Pre-cut; Punching System: Hydraulic Punching

Frequency Changer Brand: Yaskawa (Siemens optional); Power Supply: 380V 50Hz (or according to requirement)

|

C Bracing Section Roll Forming Machine

|

|

Machinable Material

|

A) Galvanized Coil

|

Thickness(MM):1.5-1.8 as per customer

|

|

|

B) PPGI,PPGL

|

|

|

|

C) Cold-rolled Steel

|

|

|

|

D) Carbon Steel

|

|

|

Yield Strength

|

250 - 350 Mpa

|

|

Tensil Stress

|

350 Mpa-500 Mpa

|

|

Nominal Forming Speed(M/Min)

|

10-15

|

* Or According To Your Requirment

|

|

Forming Station

|

About 14

|

* According To Your Profile Drawings

|

|

Decoiler

|

Manual Decoiler

|

* Hydraulic Decoiler (Optional)

|

|

Driving System

|

Chain Drive

|

* Gearbox Drive (Optional)

|

|

Machine Structure

|

Steel Plates Welded

|

* Cast Iron Stands (Optional)

|

|

Rollers’ Material

|

GCr 15

|

* Cr12Mov (Optional)

|

|

Cutting System

|

Hydraulic Pre-cut

|

|

Punching System

|

Hydraulic Punching

|

|

Frequency Changer Brand

|

Yaskawa

|

* Siemens (Optional)

|

|

Power Supply

|

380V 50Hz

|

* Or According To Your Requirment

|

|

Machine Color

|

Industrial Blue

|

* Or According To Your Requirment

|

Key Product Advantages

1. Diversified Customization: Optional hydraulic decoiler, gearbox drive, Cr12Mov rollers and Siemens frequency changer, fully adapting to different production scales and technical requirements.

2. Multi-material Adaptation: Compatible with galvanized coil, PPGI, cold-rolled steel and carbon steel, meeting anti-rust, aesthetic and strength needs of different application scenarios.

3. Flexible Parameter Adjustment: Forming speed and stations can be adjusted according to customer requirements and profile drawings, fitting non-standard C-type upright production.

Quality & Safety Assurance

Certified by SGS and TUV Rheinland, the machine undergoes full-process quality inspection. Both standard and optional components meet international industrial standards, ensuring reliable performance and product durability.

Global Service Support

Offer one-stop customized services including solution design, configuration selection, on-site debugging and lifelong accessory supply, supporting customers’ personalized production needs.

Typical Applications

Suitable for producing C-type uprights for commercial supermarket shelves, intelligent logistics racks, cold-chain warehouse shelving, special environment storage racks and customized storage systems.