| Parameter | Specification |

|---|---|

| Raw material | Cold-rolled steel, Galvanized steel (optional stainless / color-coated steel) |

| Material thickness | 1.5 – 3.0 mm |

| Roller material | GCr15 (or optional Cr12) alloy steel, heat treated (quenched / hardened) |

| Roller hardness | HRC 58 – 62° (depending on heat treatment) |

| Number of forming stations | 16 – 28 stations (profile dependent) |

| Forming (line) speed | 5 – 15 m/min (depending on profile & configuration) |

| Main motor power | 15 – 22 kW (depending on model) |

| Cutting / Shearing system | Hydraulic cutting (or saw-cut); cutting blades made of heat-treated Cr12 / Cr12MoV |

| Control system | PLC control (Siemens / Panasonic / Delta optional) — supports automatic forming, punching, cutting, length & quantity control |

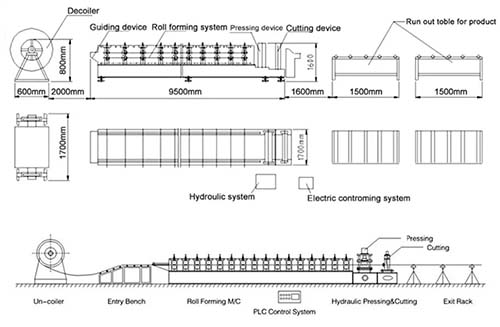

| Decoiler | manual or hydraulic decoiler (capacity configurable, e.g. 3t–5t) |

| Material width | As per customer’s profile drawing / specification |

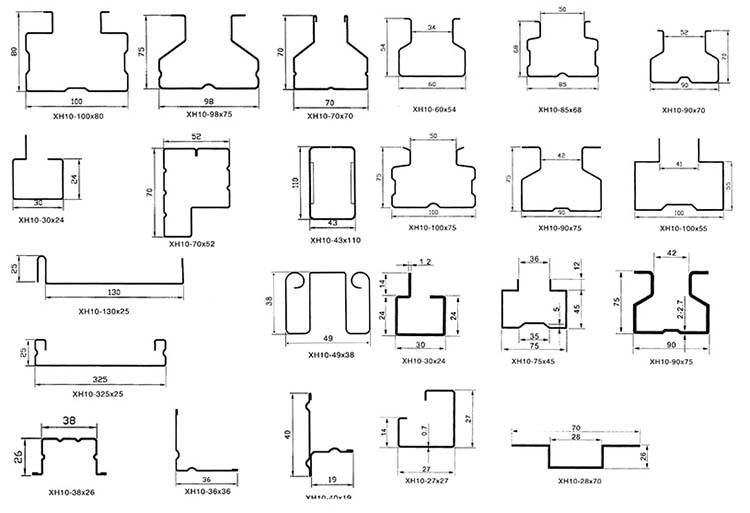

| Profile types | Upright rack columns / shelf upright posts / pallet rack uprights / warehouse shelving uprights |

| Power supply / Voltage | 380 V, 50 Hz, three-phase (customizable per customer requirement) |

Our Warehouse Shelf Upright Roll Forming Machine is specially engineered to meet the production requirements of modern storage and supermarket shelving systems. From the core mechanical structure to the intelligent control system, every component has been carefully customized to deliver precision forming, high efficiency, and superior reliability for warehouse rack manufacturers.

The machine features a modular roller assembly made from imported German alloy steel. After carburizing and quenching treatment, the roller surface hardness exceeds HRC60, ensuring durability and precision when forming 1.2–3.0 mm cold-rolled or galvanized steel sheets. The modular design allows fast roller replacement within 30 minutes, greatly improving multi-spec production efficiency.

High Precision Forming System: Equipped with Panasonic servo motors and Siemens PLC control, the Warehouse Shelf Upright Roll Forming Machine maintains forming accuracy within ±0.3 mm and ensures shelf column flatness below 0.5 mm, in full compliance with GB/T 27924-2011.

Integrated Punching & Cutting: Online punching and cutting eliminate the need for secondary processing, reducing total production time by 60%.

High Productivity: One machine can produce up to 120 shelf sets per day, quadrupling the output of traditional roll forming lines.

To ensure operator safety and product reliability, the machine integrates infrared safety sensors that automatically stop operation within 0.1 seconds upon intrusion. A real-time inspection system monitors product dimensions, automatically rejecting non-conforming items. This guarantees stable, consistent, and high-quality output throughout every production cycle.

The Warehouse Shelf Upright Roll Forming Machine supports galvanized, cold-rolled, and color-coated steel plates. Through advanced temperature and roller pressure control, it maintains coating integrity, enhances corrosion resistance, and extends the lifespan of finished shelves — ideal for both dry storage and cold chain shelf production.

| Parameter | Specification |

|---|---|

| Raw material | Cold-rolled steel, Galvanized steel (optional stainless / color-coated steel) |

| Material thickness | 1.5 – 3.0 mm |

| Roller material | GCr15 (or optional Cr12) alloy steel, heat treated (quenched / hardened) |

| Roller hardness | HRC 58 – 62° (depending on heat treatment) |

| Number of forming stations | 16 – 28 stations (profile dependent) |

| Forming (line) speed | 5 – 15 m/min (depending on profile & configuration) |

| Main motor power | 15 – 22 kW (depending on model) |

| Cutting / Shearing system | Hydraulic cutting (or saw-cut); cutting blades made of heat-treated Cr12 / Cr12MoV |

| Control system | PLC control (Siemens / Panasonic / Delta optional) — supports automatic forming, punching, cutting, length & quantity control |

| Decoiler | manual or hydraulic decoiler (capacity configurable, e.g. 3t–5t) |

| Material width | As per customer’s profile drawing / specification |

| Profile types | Upright rack columns / shelf upright posts / pallet rack uprights / warehouse shelving uprights |

| Power supply / Voltage | 380 V, 50 Hz, three-phase (customizable per customer requirement) |

We provide complete foreign trade services, including:

Pre-sales consulting: Multilingual technical support (English, Spanish, Arabic, etc.), production planning, and customized configuration proposals.

Sales support: Handling customs clearance, shipping, and installation services, with on-site technical training.

After-sales service: 24/7 online assistance, 18-month warranty for core parts, lifetime maintenance, and technical upgrades.

CE | ISO9001 | SGS | TUV

Supermarket shelf upright production

Warehouse storage rack manufacturing

Cold storage and logistics rack systems