| NO. | ITEM | UNIT | PARAMETERS |

|---|---|---|---|

| 1 | Suitable material | Pre-galvanised steel or black hot rolled steel etc | |

| MPa | ≤345Mpa | ||

| mm | 1.5mm—3.0mm | ||

| mm | 508mm | ||

| T | 5T | ||

| 2 | Specification | mm | 80-110mm |

| 3 | Line speed | m/min | 20m/min |

| 4 | Roller material | D2 quenching treatment | |

| 5 | Roller driven type | External chain transmission | |

| 6 | Operating system | Windows2000 | |

| 7 | Total motor power | KW | About 76KW |

| 8 | Electric control system | PLC automatic control system |

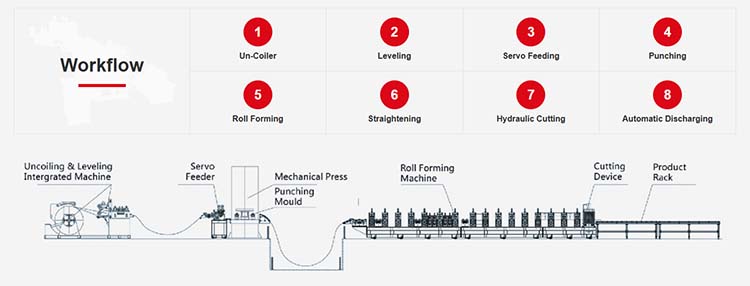

The Upright Roll Forming Machine, also known as the Pallet Shelf Roll Forming Line, is specially designed for the production of shelving and racking uprights. This intelligent roll forming system supports a wide range of profile sizes and works with material thicknesses from 1.5–3.0 mm. With fully automated processes—including decoiling, servo feeding, punching, roll forming, and hydraulic shearing—the entire production can be completed online efficiently and accurately.

Multi-size Production

One machine for multiple upright specifications. Available with automatic size changeover or manual adjustment depending on customer requirements.

Premium Roller Materials

Rollers built from high chrome-coated bearing steel (EN31) combined with high-quality tool steel (D3) for long service life and stable performance.

Overflow Coolant System

Ensures smoother surfaces and reduces tooling wear.

Hydraulic Cutting Press System

Clean cuts, stable operation, and high durability.

Closed-Loop Cut-to-Length Control

Guarantees high precision and tighter tolerances.

Plug-and-Play Electrical System

All electrical components are equipped with aviation plugs for quick connection and easy maintenance.

Roller kits of all sizes to extend roller service life

Continuous production for improved output and reduced downtime

Higher accuracy with strict part tolerances

Easy installation, simplified wiring, and low maintenance cost

| NO. | ITEM | UNIT | PARAMETERS |

|---|---|---|---|

| 1 | Suitable material | Pre-galvanised steel or black hot rolled steel etc | |

| MPa | ≤345Mpa | ||

| mm | 1.5mm—3.0mm | ||

| mm | 508mm | ||

| T | 5T | ||

| 2 | Specification | mm | 80-110mm |

| 3 | Line speed | m/min | 20m/min |

| 4 | Roller material | D2 quenching treatment | |

| 5 | Roller driven type | External chain transmission | |

| 6 | Operating system | Windows2000 | |

| 7 | Total motor power | KW | About 76KW |

| 8 | Electric control system | PLC automatic control system |

XN engineers can design tailor-made roll forming solutions according to customers’ drawings, tolerances, and budgets.

We also supply roll forming lines for box beams, step beams, and shelf panels, making it possible to build a complete pallet racking system through integrated production.