Product Overview

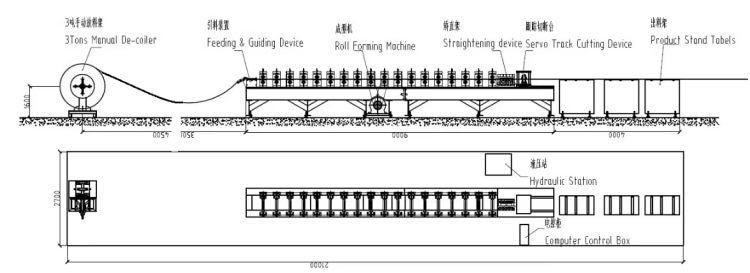

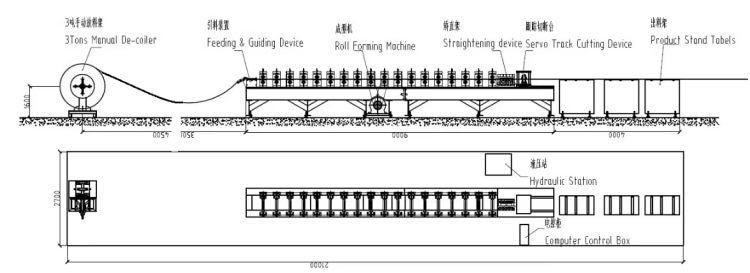

The Upright Racking Roll Forming Line is an intelligent integrated production equipment specialized in manufacturing high-precision upright rack columns. It integrates decoiling, automatic feeding, precision punching, continuous roll forming, and high-precision cutting into a seamless workflow. Equipped with advanced PLC control technology and high-hardness alloy steel rollers, it ensures stable, efficient, and consistent mass production, perfectly meeting the strict quality requirements of industrial warehouses, large-scale logistics hubs, and commercial storage facilities.

Core Technical Specifications

-

Raw material: Cold-rolled steel, Galvanized steel (optional stainless / color-coated steel)

-

Material thickness: 1.5 – 3.0 mm

-

Roller material: GCr15 (or optional Cr12) alloy steel, heat treated (quenched / hardened)

-

Roller hardness: HRC 58 – 62° (depending on heat treatment)

-

Number of forming stations: 16 – 28 stations (profile dependent)

-

Forming (line) speed: 5 – 15 m/min (depending on profile & configuration)

-

Main motor power: 15 – 22 kW (depending on model)

-

Cutting / Shearing system:Hydraulic cutting (or saw-cut); cutting blades made of heat-treated Cr12 / Cr12MoV

-

Control system: PLC control (Siemens / Panasonic / Delta optional) — supports automatic forming, punching, cutting, length & quantity control

-

Decoiler: Manual or hydraulic decoiler (capacity configurable, e.g. 3t–5t)

-

Material width: As per customer’s profile drawing / specification

-

Profile types: Upright rack columns / shelf upright posts / pallet rack uprights / warehouse shelving uprights

-

Power supply / Voltage: 380 V, 50 Hz, three-phase (customizable per customer requirement)

Key Product Advantages

1. High-Precision Intelligent Forming: Adopting 16-28 adjustable forming stations and high-hardness heat-treated rollers, combined with renowned brand PLC control, the line achieves ±0.5mm dimensional accuracy and smooth surface finish, ensuring assembly stability of upright racks.

2. Efficient Integrated Production: The seamless integration of multiple processes eliminates manual transfer links, with a forming speed of 5-15 m/min to meet large-batch production needs, improving overall efficiency by 40% compared to traditional equipment.

3. Comprehensive Safety Protection: Equipped with emergency stop buttons, safety guards, and real-time fault monitoring system, which automatically alarms and shuts down when abnormalities occur, fully safeguarding operator safety and production continuity.

Quality & Safety Assurance

All components undergo rigorous quality inspection and performance testing before delivery, complying with international industrial standards and holding CE, ISO9001:2015 certifications. The strict quality control system ensures the line's long-term reliable operation and product consistency.

Global Service Support

We provide multilingual pre-sales consultation, on-site factory layout planning, customized solutions, on-site installation and commissioning, and 24/7 after-sales technical support, ensuring customers enjoy a worry-free user experience.

Typical Applications

Widely used in the production of upright rack columns for industrial storage racks, large logistics distribution center racks, commercial supermarket racks, and cold-chain storage racks.