Product Overview

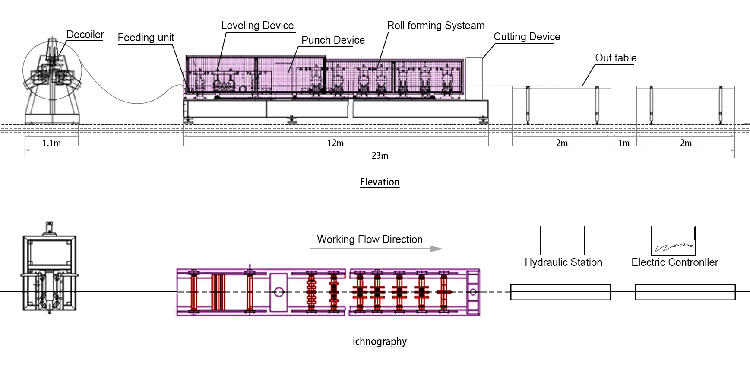

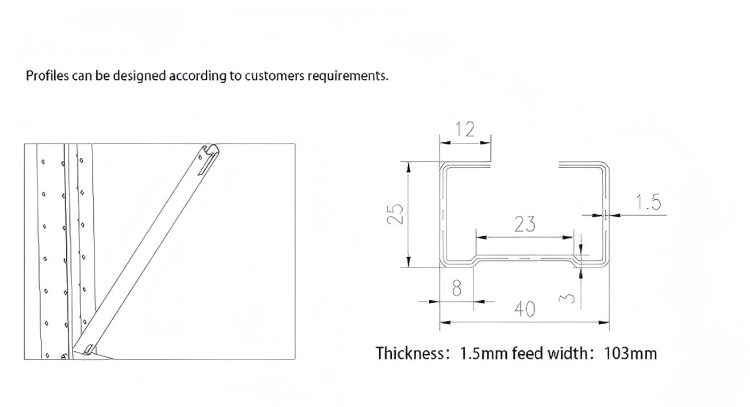

This intelligent and eco-friendly machine is tailored for high-standard C-type shelf upright production. Equipped with high-performance frequency changers and energy-saving components, it realizes precise control and low energy consumption, fitting modern green production needs.

Core Technical Specifications

Machinable Material: Galvanized Coil, PPGI, PPGL, Cold-rolled Steel, Carbon Steel (Thickness: 1.5-1.8 mm as per customer)

Yield Strength:250 - 350 Mpa; Tensil Stress: 350 Mpa-500 Mpa

Nominal Forming Speed: 10-15 m/min (or according to requirement); Forming Station: About 14 (according to profile drawings)

Decoiler:Manual Decoiler (Hydraulic Decoiler optional); Driving System: Chain Drive (Gearbox Drive optional)

Machine Structure: Steel Plates Welded (Cast Iron Stands optional); Rollers’ Material: GCr 15 (Cr12Mov optional)

Cutting System: Hydraulic Pre-cut; Punching System: Hydraulic Punching

Frequency Changer Brand: Yaskawa (Siemens optional); Power Supply: 380V 50Hz (or according to requirement)

|

C Bracing Section Roll Forming Machine

|

|

Machinable Material

|

A) Galvanized Coil

|

Thickness(MM):1.5-1.8 as per customer

|

|

|

B) PPGI,PPGL

|

|

|

|

C) Cold-rolled Steel

|

|

|

|

D) Carbon Steel

|

|

|

Yield Strength

|

250 - 350 Mpa

|

|

Tensil Stress

|

350 Mpa-500 Mpa

|

|

Nominal Forming Speed(M/Min)

|

10-15

|

* Or According To Your Requirment

|

|

Forming Station

|

About 14

|

* According To Your Profile Drawings

|

|

Decoiler

|

Manual Decoiler

|

* Hydraulic Decoiler (Optional)

|

|

Driving System

|

Chain Drive

|

* Gearbox Drive (Optional)

|

|

Machine Structure

|

Steel Plates Welded

|

* Cast Iron Stands (Optional)

|

|

Rollers’ Material

|

GCr 15

|

* Cr12Mov (Optional)

|

|

Cutting System

|

Hydraulic Pre-cut

|

|

Punching System

|

Hydraulic Punching

|

|

Frequency Changer Brand

|

Yaskawa

|

* Siemens (Optional)

|

|

Power Supply

|

380V 50Hz

|

* Or According To Your Requirment

|

|

Machine Color

|

Industrial Blue

|

* Or According To Your Requirment

|

Key Product Advantages

1. Intelligent Precision Control: Yaskawa (or Siemens) frequency changer enables stepless speed regulation and stable operation, ensuring precise forming of C-type uprights.

2. Energy-saving & Eco-friendly: Optimized driving system and energy-efficient components reduce power consumption, complying with global green production standards.

3. High-performance Output: Hydraulic punching and pre-cut systems ensure clean cuts and accurate holes, meeting high-standard C-type upright assembly requirements.

Quality & Safety Assurance

Compliant with RoHS, REACH environmental standards and ISO9001:2015, the machine features low noise and no pollution, ensuring safe and eco-friendly production.

Global Service Support

Provide green production solutions, intelligent operation training, on-site commissioning and 24/7 after-sales support, helping customers achieve sustainable and efficient production.

Typical Applications

Ideal for producing high-standard C-type uprights for eco-industrial parks, green logistics centers, high-end commercial facilities, food cold-chain racks and intelligent storage systems.