| Line Specifications | |

|---|---|

| Weight | About 15,800 kgs |

| Whole Line Dimension | About 20 m × 1.5 m × 1.5 m (L × W × H) |

| Color | Main color: blue Warning color: yellow |

| Suitable Raw Material | Galvanized or Galvalume Coils |

| Thickness | 0.8 ‒ 2.5 mm |

| Coil Width | According to product size |

| Yield Strength | 250 ‒ 400 MPa |

| Quantity of Forming Roller Stations | About 19 |

| Diameter of Forming Roller Shafts | 75 mm |

| Roll Forming Speed | 20 m/min |

| Production Speed | 20 m/min |

| Forming Rollers Material | Cr12 mold steel, quenched treated |

| Cutter Material | Cr12 mold steel, quenched treated |

| <stron | |

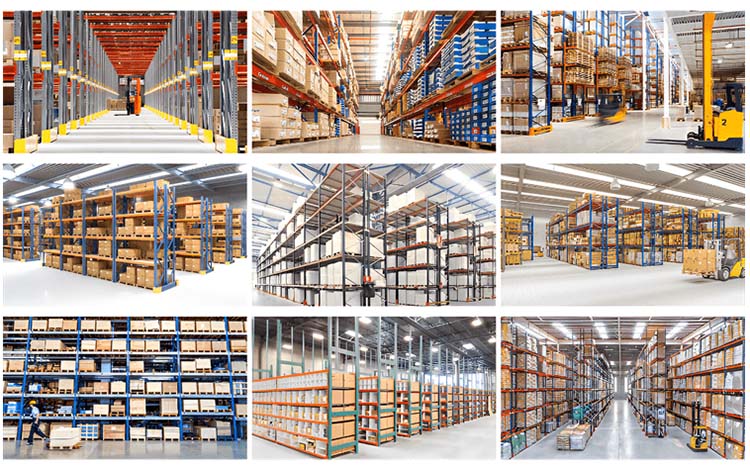

Product Overview

Our Rack Upright Roll Forming Machine is an advanced and efficient machine specifically designed to manufacture upright frames (upright columns) for warehouse pallet racking systems. The integrated line includes a decoiler, guide, leveler, hydraulic punch, main roll forming unit, hydraulic cutter, electrical control system, and output table — all working in sync to produce high-quality rack uprights. High‑Speed Rack Upright Roll Forming Machine

Key Components & Working Process

Decoiler — Unwinds the metal coil steadily to feed the production line.

Guide — Keeps the metal strip properly aligned throughout the forming process.

Leveler — Straightens and flattens the strip to guarantee uniformity before forming.

Hydraulic Punching — Punches teardrop holes, slots, or other patterns, providing flexibility for different beam mounting methods.

Roll Forming — Uses a series of precisely arranged rollers to shape the strip into upright profiles with consistency and accuracy.

Hydraulic Cutting — Cuts the formed uprights to the desired length with high precision.

Output Table — Collects the finished uprights, ready for stacking or shipping.

Electrical Control System — A PLC-based system ensures all processes (forming, punching, cutting) are synchronized and automated.

| Line Specifications | |

|---|---|

| Weight | About 15,800 kgs |

| Whole Line Dimension | About 20 m × 1.5 m × 1.5 m (L × W × H) |

| Color | Main color: blue Warning color: yellow |

| Suitable Raw Material | Galvanized or Galvalume Coils |

| Thickness | 0.8 ‒ 2.5 mm |

| Coil Width | According to product size |

| Yield Strength | 250 ‒ 400 MPa |

| Quantity of Forming Roller Stations | About 19 |

| Diameter of Forming Roller Shafts | 75 mm |

| Roll Forming Speed | 20 m/min |

| Production Speed | 20 m/min |

| Forming Rollers Material | Cr12 mold steel, quenched treated |

| Cutter Material | Cr12 mold steel, quenched treated |

Material & Size Flexibility

Supports various raw materials: cold-rolled steel, galvanized coil, PPGI, carbon steel, stainless steel, and aluminum.

Adjustable thickness: up to 3.0 mm for heavy-duty uprights.

Custom dimensions: we design uprights based on your load capacity and drawing requirements, including punch-pattern design (e.g., teardrop holes).

High Automation & Efficiency

The machine offers a fully automated workflow: decoiling → leveling → feeding → punching → forming → cutting → output. This ensures fast, continuous production with minimal manual intervention.

Quality & Standards

Produced upright profiles conform to industry standards for pallet racking systems, providing reliability and structural strength.

Customization & Service

We offer tailored solutions based on your profile drawings, dimensional tolerances, and production budget. Our one-to-one service ensures the final machine matches your exact requirements.

Global Experience

Our machines have been successfully exported to multiple markets, demonstrating robust performance and international adaptability.