Product Overview

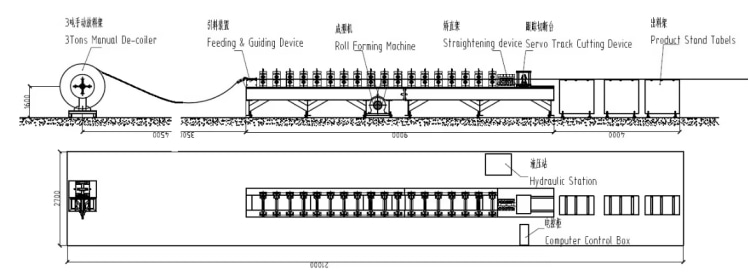

The Upright Rack Roll Forming Machine Production Line is an integrated automated production solution specifically engineered for manufacturing high-precision upright rack columns, the core load-bearing components of storage rack systems. This production line integrates decoiling, feeding, punching, forming, cutting and other processes, realizing one-stop continuous production. With advanced intelligent control technology and stable forming performance, it can efficiently produce high-quality upright racks that meet industrial storage standards, and is widely recognized by global storage rack manufacturers for its high efficiency, reliability and strong adaptability.

Core Technical Specifications

-

Raw material: Cold-rolled steel, Galvanized steel (optional stainless / color-coated steel), covering mainstream and customized material demands for upright rack production

-

Material thickness: 1.5 – 3.0 mm, perfectly matching the thickness requirement of high-strength upright rack columns

-

Roller material: GCr15 (or optional Cr12) alloy steel, heat treated (quenched / hardened), featuring excellent wear resistance and deformation resistance for long-term stable operation

-

Roller hardness: HRC 58 – 62° (depending on heat treatment), ensuring high forming precision and prolonging roller service life

-

Number of forming stations: 16 – 28 stations (profile dependent), adaptable to different upright rack profile structures to achieve uniform stress distribution and perfect forming effect

-

Forming (line) speed: 5 – 15 m/min (depending on profile & configuration), balancing high production efficiency and product quality to meet large-batch production demands

-

Main motor power: 15 – 22 kW (depending on model), providing stable and sufficient power support for the entire production line

-

Cutting / Shearing system:Hydraulic cutting (or saw-cut); cutting blades made of heat-treated Cr12 / Cr12MoV, ensuring smooth cutting surfaces, high precision and no burrs

-

Control system: PLC control (Siemens / Panasonic / Delta optional) — supports automatic forming, punching, cutting, length & quantity control, realizing intelligent full-process control and reducing manual intervention

-

Decoiler: Manual or hydraulic decoiler (capacity configurable, e.g. 3t–5t), matching different production scales and material handling requirements

-

Material width: As per customer’s profile drawing / specification, fully customized to meet unique upright rack profile design needs

-

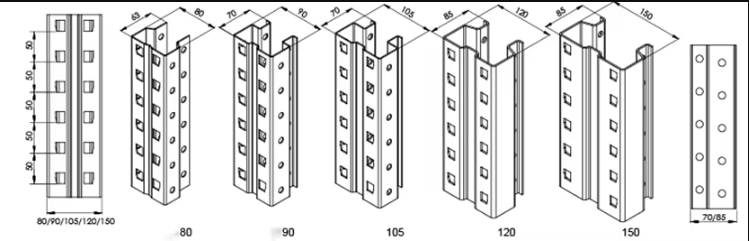

Profile types: Industrial storage upright racks, pallet rack upright columns, warehouse shelving upright posts, covering core upright rack application types

-

Power supply / Voltage: 380 V, 50 Hz, three-phase (customizable per customer requirement), adaptable to power standards of different regions worldwide

Global One-Stop Service

Pre-sales Consulting

We provide multilingual technical support (English, German, Russian, Spanish, Arabic), on-site factory layout planning, and customized production line solutions based on customers' specific upright rack profile drawings, material requirements, production scales and regional power standards.

Sales Support

Professional packaging is adopted for the production line equipment to prevent damage during transportation. We provide complete industrial equipment customs clearance documents and arrange professional engineers to conduct on-site installation, commissioning and debugging. Systematic training on production line operation, maintenance and quality control is provided for customer teams to ensure they can proficiently use the equipment.

After-sales Service

24/7 online technical assistance is available to solve customers' problems in a timely manner. On-site maintenance support is provided within 48 hours in key regions. We offer a long-term warranty for core components of the production line, provide lifelong maintenance guidance and free software upgrade services, ensuring the continuous and stable operation of the production line.

Certifications

CE | ISO9001:2015 | SGS | TUV Rheinland

Typical Applications

-

Production of upright rack columns for heavy-duty industrial storage racks

-

Manufacturing of pallet rack upright columns for logistics distribution centers

-

Customized production of warehouse shelving upright posts for commercial retail warehouses

-

Production of high-strength upright racks for cold-chain storage and chemical storage facilities