Product Description

Product Overview

Our Automatic Storage Rack Beam Roll Forming Machine Line is a fully integrated production system dedicated to manufacturing high-strength storage rack beams—core load-bearing parts for intelligent warehouses, industrial storage systems, and logistics distribution centers. Integrating unmanned production, precision forming control, and multi-spec compatibility, it serves as a production backbone for rack manufacturers in 115+ countries, adapting to the efficient production needs of heavy-duty and medium-duty storage racks.

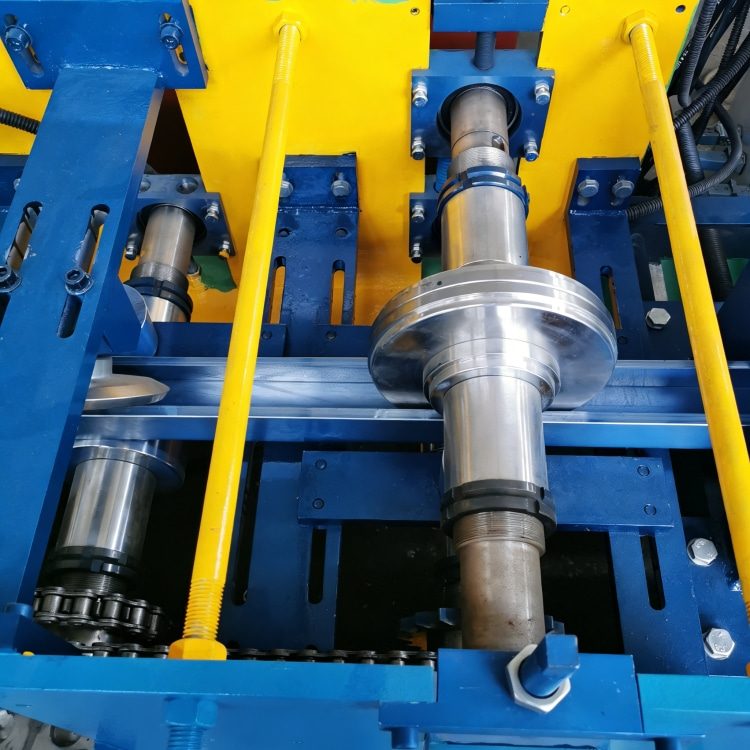

The line is equipped with ultra-wear-resistant roller sets made from imported Austrian 20CrMnTi alloy steel. After vacuum carburizing and 5-axis precision grinding, the roller surface hardness reaches HRC64, enabling stable processing of 1.2–3.8 mm Q355B/Q420 high-strength carbon steel and zinc-aluminum-magnesium coated steel. Its servo-driven quick-change system completes mold replacement within 16 minutes, supporting beams with widths from 180mm to 600mm and heights from 100mm to 300mm.

Technical Advantages

High-Precision Forming System: Adopting Delta high-torque servo motors and Siemens S7-1500 PLC control, the line maintains beam dimensional accuracy within±0.2 mm and flange straightness below 0.3 mm/m, fully complying with GB/T 27924-2011 and ANSI MH16.3 standards.

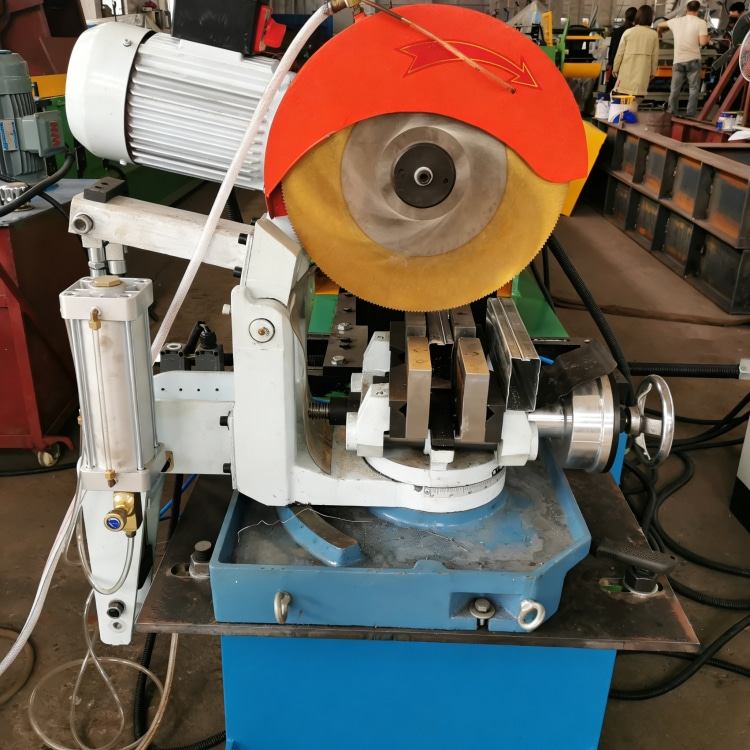

Full-Process Automation: The integrated workflow covers automatic uncoiling, dual-sided leveling, multi-pass forming, online punching, flange trimming, and servo cutting—reducing manual intervention to 0%, shortening production cycle by 62%, and lowering material waste to 0.9%.

Industrial-Grade Productivity: A single line can produce up to 160 sets of storage rack beams per day, 4 times the output of semi-automatic equipment, easily meeting bulk orders for intelligent warehouse projects.

Safety & Quality Assurance

Equipped with 7-group infrared safety gratings and dual emergency stop systems, the line achieves shutdown response within 0.04 seconds. A 3D laser inspection system real-time monitors beam thickness, hole position accuracy, and weld quality, ensuring each beam bears a minimum load of 2000 kg without deformation, guaranteeing shelf structural safety.

Material Compatibility

It specializes in processing high-performance materials, including 1.2–3.8 mm Q355B/Q420 carbon steel, hot-dip galvanized steel (zinc layer ≥ 180g/m²), and weather-resistant steel. Adaptive roller pressure control (adjustable within 10–22 MPa) and circulating cooling preserve material toughness, making finished beams suitable for cold storage, outdoor stockyards, and chemical warehouses.

One-Stop Global Service

Pre-sales: Multilingual support (English/German/Russian/Arabic), on-site layout planning, and beam load-bearing simulation for seismic zones.

Sales: Heavy-equipment packaging, customs clearance, on-site installation, and 8-day operation/maintenance training.

After-sales: 24/7 on-call engineers, 36-month warranty for core parts (rollers/servos), lifetime maintenance, and 5-year free upgrades.

Certifications

CE | ISO9001 | SGS | TUV | ANSI MH16.3 | DIN EN 15512 | GB/T 27924-2011

Typical Applications

Beam production for intelligent storage racks

High-load beams for logistics center storage systems

Corrosion-resistant beams for cold-chain/chemical racks

Special beams for automotive/electronics warehouse racks