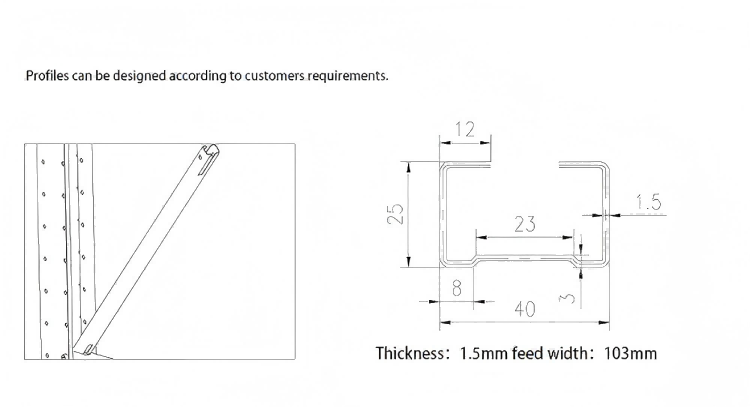

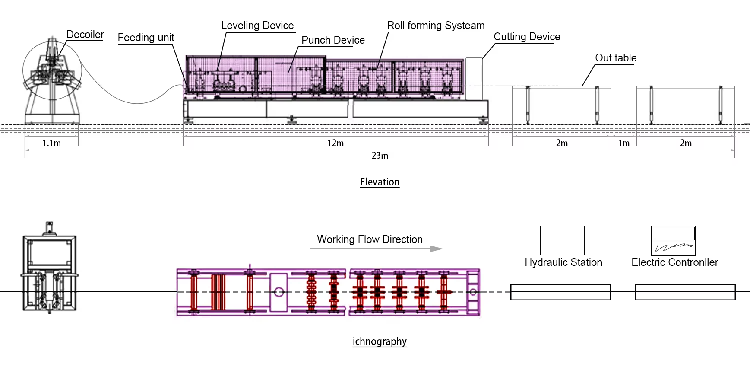

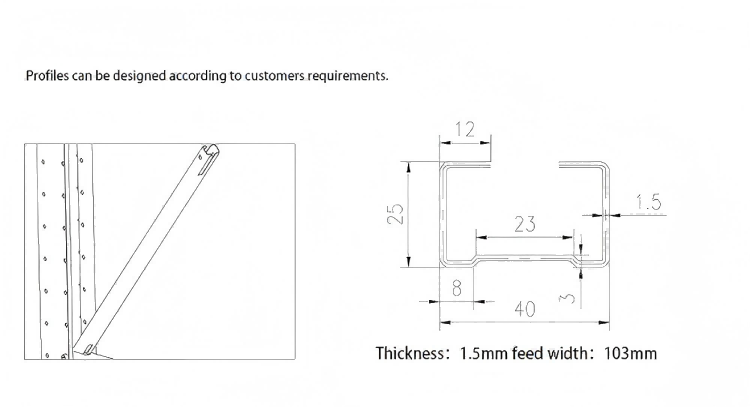

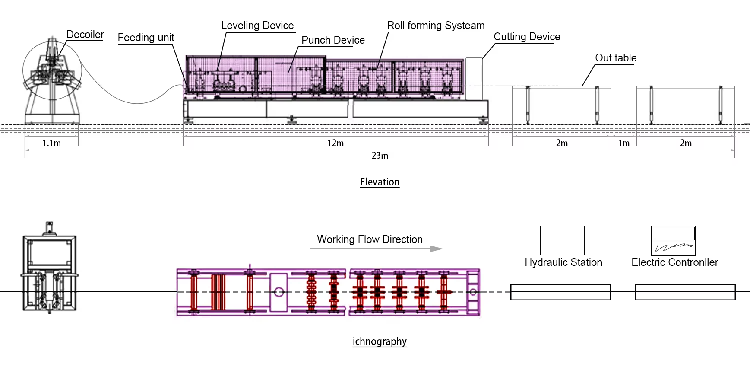

As a specialized piece of equipment for producing C-section uprights used in rack bracing systems, this roll forming machine combines advanced technology with flexible customization to cater to global rack manufacturing needs. It is designed to process a wide spectrum of raw materials: Galvanized Coil (thickness 1.5-1.8MM, customizable), PPGI, PPGL, Cold-rolled Steel and Carbon Steel, making it ideal for projects with varying material quality and corrosion resistance requirements. The machine is calibrated to handle materials with Yield Strength of 250 - 350 Mpa and Tensil Stress of 350 Mpa-500 Mpa, ensuring the formed products meet international load-bearing standards.

With a Nominal Forming Speed of 10-15 M/Min (adjustable on request) and approximately 14 Forming Stations (customized to profile drawings), it enables high-volume production while maintaining tight dimensional tolerances. The decoiling unit offers two options: a standard Manual Decoiler for small-batch production and an optional Hydraulic Decoiler for automated, high-efficiency lines. The driving system features a standard Chain Drive for cost-effective reliability, with an optional Gearbox Drive for applications requiring higher precision and stability. The machine’s base structure is Steel Plates Welded as standard, with Cast Iron Stands available as an upgrade to minimize vibration during high-speed forming.

|

C Bracing Section Roll Forming Machine

|

|

Machinable Material

|

A) Galvanized Coil

|

Thickness(MM):1.5-1.8 as per customer

|

|

|

B) PPGI,PPGL

|

|

|

|

C) Cold-rolled Steel

|

|

|

|

D) Carbon Steel

|

|

|

Yield Strength

|

250 - 350 Mpa

|

|

Tensil Stress

|

350 Mpa-500 Mpa

|

|

Nominal Forming Speed(M/Min)

|

10-15

|

* Or According To Your Requirment

|

|

Forming Station

|

About 14

|

* According To Your Profile Drawings

|

|

Decoiler

|

Manual Decoiler

|

* Hydraulic Decoiler (Optional)

|

|

Driving System

|

Chain Drive

|

* Gearbox Drive (Optional)

|

|

Machine Structure

|

Steel Plates Welded

|

* Cast Iron Stands (Optional)

|

|

Rollers’ Material

|

GCr 15

|

* Cr12Mov (Optional)

|

|

Cutting System

|

Hydraulic Pre-cut

|

|

Punching System

|

Hydraulic Punching

|

|

Frequency Changer Brand

|

Yaskawa

|

* Siemens (Optional)

|

|

Power Supply

|

380V 50Hz

|

* Or According To Your Requirment

|

|

Machine Color

|

Industrial Blue

|

* Or According To Your Requirment

|

The core forming components use GCr 15 rollers (optional Cr12Mov rollers for wear resistance in continuous operation), ensuring consistent profile quality. The Hydraulic Pre-cut System and Hydraulic Punching System deliver precise, burr-free cutting and punching, eliminating the need for post-processing. A Yaskawa frequency changer is installed for smooth speed control, with Siemens as an optional alternative. The machine operates on 380V 50Hz power (customizable to local standards) and comes in industrial blue as standard, with color customization available to align with your brand identity.