roduct Overview

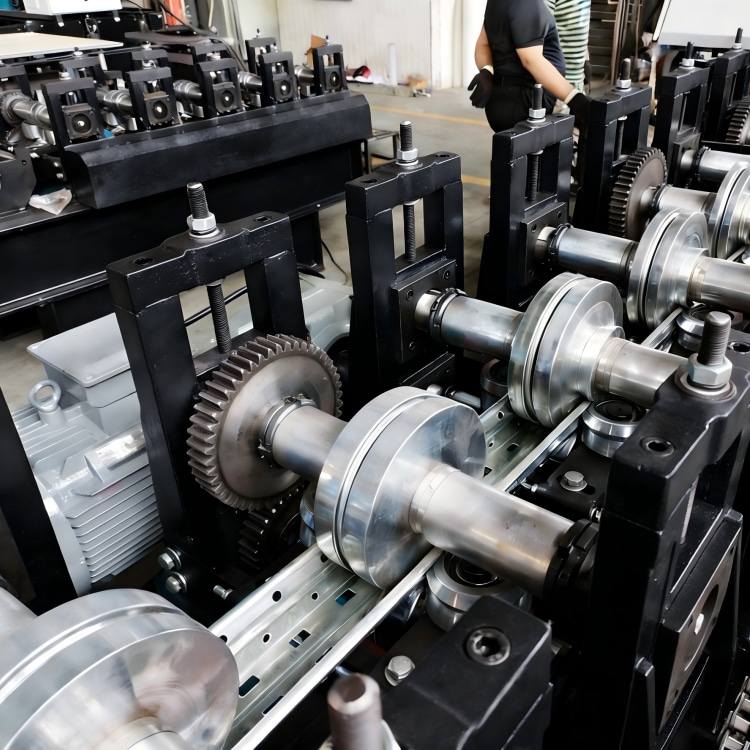

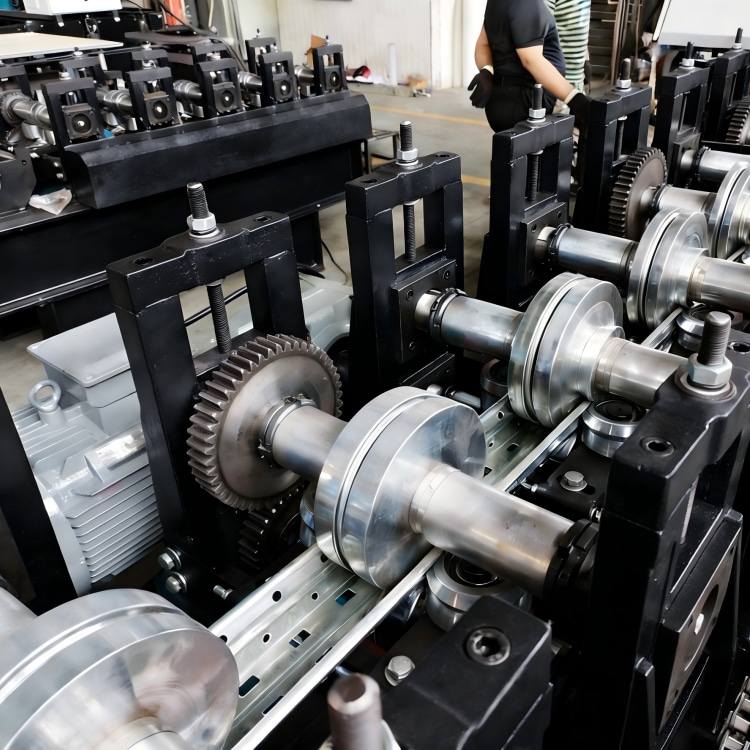

The Racks Roll Forming Machine is a high-end durable production equipment engineered for manufacturing high-strength, precision shelf uprights. Integrating premium material selection, sophisticated mechanical design, and intelligent control, it realizes a smooth production process from raw material uncoiling to finished product output. Designed to adapt to the rigorous production demands of global high-end storage equipment industry, this machine boasts excellent stability, wear resistance, and adaptability, providing a reliable production guarantee for manufacturers aiming at high-quality storage rack markets.

Core Technical Specifications

-

Raw material: Cold-rolled steel, Galvanized steel (optional stainless / color-coated steel)

-

Material thickness: 1.5 – 3.0 mm

-

Roller material: GCr15 (or optional Cr12) alloy steel, heat treated (quenched / hardened)

-

Roller hardness: HRC 58 – 62° (depending on heat treatment)

-

Number of forming stations: 16 – 28 stations (profile dependent)

-

Forming (line) speed: 5 – 15 m/min (depending on profile & configuration)

-

Main motor power: 15 – 22 kW (depending on model)

-

Cutting / Shearing system:Hydraulic cutting (or saw-cut); cutting blades made of heat-treated Cr12 / Cr12MoV

-

Control system: PLC control (Siemens / Panasonic / Delta optional) — supports automatic forming, punching, cutting, length & quantity control

-

Decoiler: Manual or hydraulic decoiler (capacity configurable, e.g. 3t–5t)

-

Material width: As per customer’s profile drawing / specification

-

Profile types: Upright rack columns / shelf upright posts / pallet rack uprights / warehouse shelving uprights

-

Power supply / Voltage: 380 V, 50 Hz, three-phase (customizable per customer requirement)

Key Product Advantages

1. Premium Durable Material Guarantee: Core components like rollers and cutting blades adopt heat-treated high-grade alloy steel, featuring superior wear resistance and deformation resistance. The machine can maintain stable performance during long-term continuous operation, significantly extending the service life and reducing replacement costs of vulnerable parts.

2. Strong Full-Process Adaptability: With 16-28 adjustable forming stations and customizable material width & profile specifications, it can flexibly match the production needs of different types of shelf uprights. The compatible multiple raw material types and power supply standards enable it to adapt to diverse regional production conditions globally.

3. Intelligent Monitoring & Easy Maintenance: The PLC control system is equipped with intelligent fault diagnosis and data monitoring functions, which can timely feedback equipment operation status. The optimized structural design makes key components easy to disassemble and maintain, reducing downtime and improving equipment utilization rate.

Quality & Safety Assurance

The machine adheres to strict high-end manufacturing standards, with each component undergoing multiple rounds of quality inspection and performance testing. It has obtained authoritative certifications such as CE, ISO9001:2015 and TUV Rheinland, ensuring that the product quality, safety performance and environmental protection indicators meet the high requirements of global high-end markets.

Global Service Support

We provide customized pre-sales technical solution design, high-standard on-site installation and commissioning, professional operator training, and 24/7 global after-sales technical support. We also offer long-term supply of genuine accessories and lifelong maintenance guidance to ensure the continuous and efficient operation of the equipment.

Typical Applications

Widely applicable to the production of high-strength shelf uprights for precision industrial storage, large-scale intelligent logistics hubs, high-end commercial display racks, and special environment (high-humidity, chemical) storage systems, fully meeting the high load-bearing and high-precision requirements of these scenarios.