Product Overview

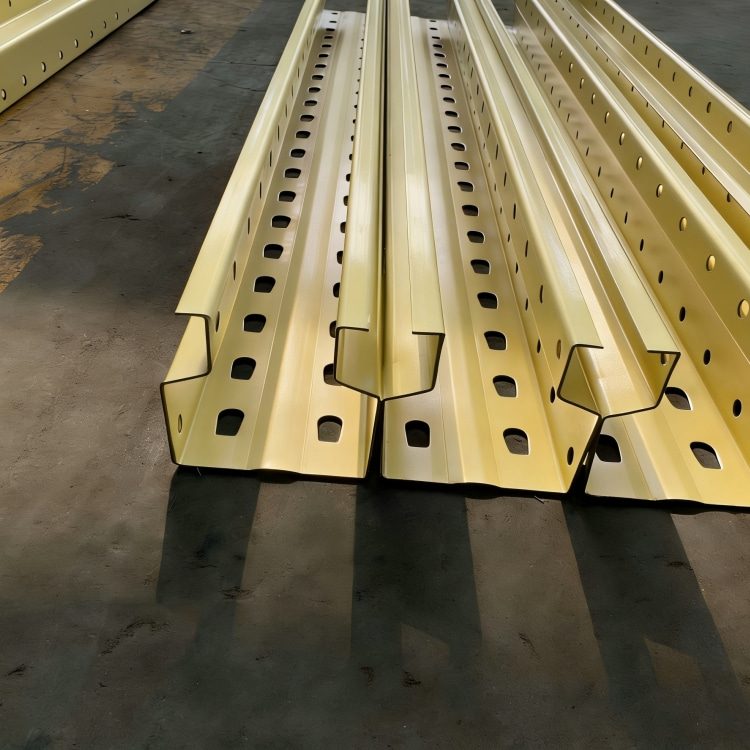

The Punch Mould For Rack Upright is a professional durable component designed for the high-strength punching needs of shelf uprights. With strong customization capabilities, it can be tailored to different upright profiles and punching requirements. The mould adopts scientific heat treatment process and precise structural design, featuring excellent wear resistance and impact resistance, which can stably adapt to long-term high-frequency punching production, providing reliable support for rack manufacturers to improve product quality and production efficiency.

Core Technical Specifications

-

Applicable raw material: Cold-rolled steel, Galvanized steel (optional stainless / color-coated steel)

-

Applicable material thickness: 1.5 – 3.0 mm

-

Mould material: GCr15 (or optional Cr12) alloy steel, heat treated (quenched / hardened)

-

Mould hardness: HRC 58 – 62° (depending on heat treatment)

-

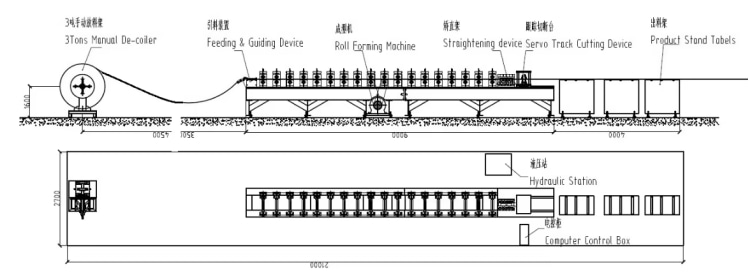

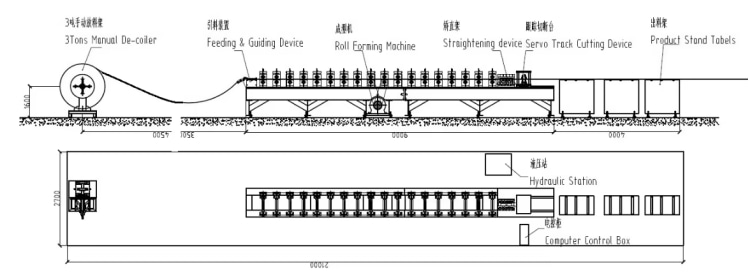

Matching forming stations: 16 – 28 stations (profile dependent)

-

Adaptable forming speed: 5 – 15 m/min (depending on profile & configuration)

-

Matching cutting system: Compatible with hydraulic cutting / saw-cut systems (cutting blades made of heat-treated Cr12 / Cr12MoV)

-

Applicable profile types: Upright rack columns / shelf upright posts / pallet rack uprights / warehouse shelving uprights

-

Customization scope: As per customer’s profile drawing / specification (punching shape, spacing, depth)

-

Matching decoiler:Adaptable to manual / hydraulic decoiler (3t–5t capacity)

Key Product Advantages

1. Durable & Wear-Resistant: Premium alloy steel material and strict heat treatment process ensure the mould has high hardness and excellent wear resistance, with a service life 30% longer than ordinary moulds.

2. Strong Customization Capability: Supports full customization of punching parameters according to customer upright drawings, adapting to the production needs of various special-shaped and high-strength shelf uprights.

3. Stable High-Frequency Operation: Optimized structural design reduces vibration during high-speed punching, ensuring stable mould performance even under long-term high-frequency operation, with low failure rate.

Quality & Safety Assurance

The mould is manufactured in strict accordance with international quality management system standards, with complete inspection procedures from raw material procurement to finished product delivery. It has obtained SGS and TUV Rheinland certifications, ensuring that the product quality and safety performance meet global market requirements.

Global Service Support

We provide one-stop services including personalized mould design, main machine matching test, on-site installation guidance, operator training on mould use and maintenance, and long-term supply of mould accessories, ensuring the smooth operation of customers' production lines.

Typical Applications

Suitable for the punching process of shelf uprights for heavy-duty industrial racks, intelligent logistics center racks, premium commercial storage racks, and special environment (cold-chain, chemical) storage racks, matching various high-intensity production scenarios.