Product Overview

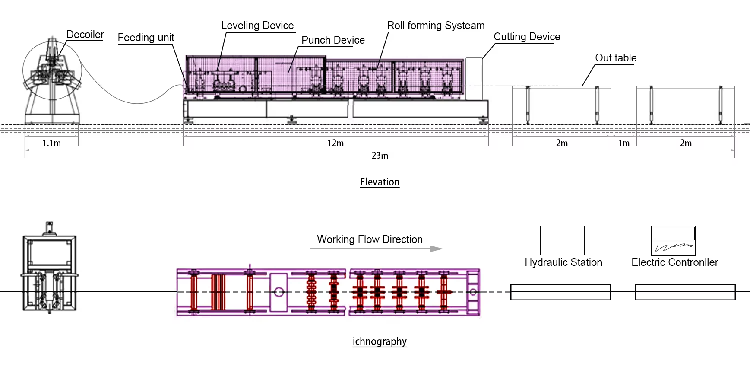

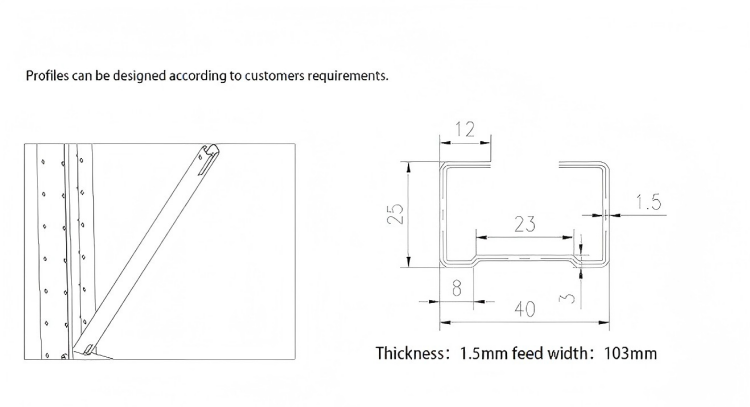

This machine is specialized in high-precision production of C-type shelf uprights, integrating automatic decoiling, forming, punching and cutting processes. With stable performance and efficient output, it perfectly meets the assembly and load-bearing needs of industrial storage racks and logistics shelving systems.

Core Technical Specifications

Machinable Material: Galvanized Coil, PPGI, PPGL, Cold-rolled Steel, Carbon Steel (Thickness: 1.5-1.8 mm as per customer)

Yield Strength: 250 - 350 Mpa; Tensil Stress: 350 Mpa-500 Mpa

Nominal Forming Speed: 10-15 m/min (or according to requirement); Forming Station: About 14 (according to profile drawings)

Decoiler: Manual Decoiler (Hydraulic Decoiler optional); Driving System: Chain Drive (Gearbox Drive optional)

Machine Structure: Steel Plates Welded (Cast Iron Stands optional); Rollers’ Material: GCr 15 (Cr12Mov optional)

Cutting System: Hydraulic Pre-cut; Punching System: Hydraulic Punching

Frequency Changer Brand: Yaskawa (Siemens optional); Power Supply: 380V 50Hz (or according to requirement)

|

C Bracing Section Roll Forming Machine

|

|

Machinable Material

|

A) Galvanized Coil

|

Thickness(MM):1.5-1.8 as per customer

|

|

|

B) PPGI,PPGL

|

|

|

|

C) Cold-rolled Steel

|

|

|

|

D) Carbon Steel

|

|

|

Yield Strength

|

250 - 350 Mpa

|

|

Tensil Stress

|

350 Mpa-500 Mpa

|

|

Nominal Forming Speed(M/Min)

|

10-15

|

* Or According To Your Requirment

|

|

Forming Station

|

About 14

|

* According To Your Profile Drawings

|

|

Decoiler

|

Manual Decoiler

|

* Hydraulic Decoiler (Optional)

|

|

Driving System

|

Chain Drive

|

* Gearbox Drive (Optional)

|

|

Machine Structure

|

Steel Plates Welded

|

* Cast Iron Stands (Optional)

|

|

Rollers’ Material

|

GCr 15

|

* Cr12Mov (Optional)

|

|

Cutting System

|

Hydraulic Pre-cut

|

|

Punching System

|

Hydraulic Punching

|

|

Frequency Changer Brand

|

Yaskawa

|

* Siemens (Optional)

|

|

Power Supply

|

380V 50Hz

|

* Or According To Your Requirment

|

|

Machine Color

|

Industrial Blue

|

* Or According To Your Requirment

|

Key Product Advantages

1. High Efficiency & Precision: 10-15 m/min forming speed and 14 forming stations ensure fast production and precise shaping of C-type uprights, reducing dimensional errors.

2. Integrated Automation: Hydraulic pre-cut and punching systems work seamlessly, realizing one-stop production from material feeding to finished product output.

3. Stable Load-bearing Performance: Adapts to materials with 250-350 Mpa yield strength, ensuring the produced C-type uprights have excellent structural strength and load-bearing capacity.

Quality & Safety Assurance

Compliant with CE, ISO9001:2015 standards, all core components (including GCr15 rollers and Yaskawa frequency changer) undergo rigorous testing to ensure long-term stable operation and product quality consistency.

Global Service Support

Provide multilingual consultation, on-site installation & commissioning, operator training and 24/7 after-sales support, ensuring worry-free use for customers worldwide.

Typical Applications

Widely used in producing C-type uprights for industrial storage racks, warehouse shelving, pallet racks, logistics distribution center shelves and light-duty to medium-duty storage equipment.