Contact Person: XN Duan

Mobile Phone:18832797029

WhatsApp:+86 18832797029

E-mail:yuankuoduan@gmail.com

Add:Zhenggang Road, Industrial Development Zone, Botou City, Hebei Province

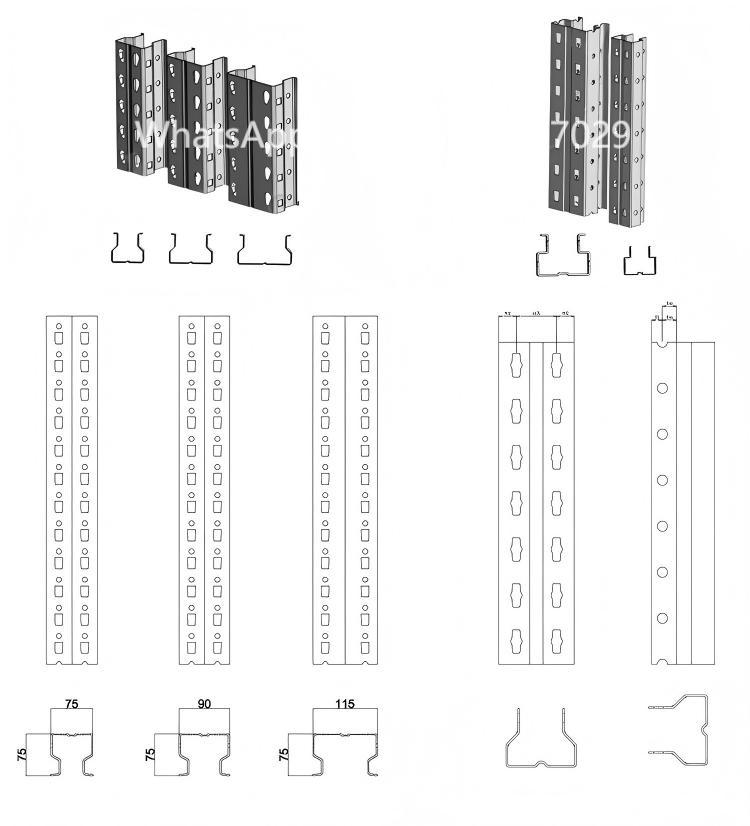

Xinnuo’s Warehouse Rack Upright Roll Forming Machine, also called Pallet Racking Roll Forming Machine, is specialized in producing upright frames—core components for warehouse pallet racking systems. This intelligent equipment is engineered to manufacture various sizes of uprights with a thickness range of 1.5-3.0mm, integrating full-process automation on one production line.

|

Warehouse Shelf Upright Roll Forming Machine |

||

|

Machinable Material |

A) Galvanized Steel |

Thickness(MM):1.5–3.0 as per customer |

|

|

B) Stainless Steel |

|

|

Yield Strength |

250 – 550 Mpa |

|

|

Tensil Stress |

G250 Mpa–G550 Mpa |

|

|

Decoiler |

Manual Decoiler |

* Hydraulic Decoiler (Optional) |

|

Punching System |

Hydraulic Punching Station |

* Punching Press (Optional) |

|

Forming Station |

About 25 Stands |

* According To Your Profile Drawings |

|

Driving System |

Chain Drive |

* Gearbox Drive (Optional) |

|

Machine Structure |

Wall Panel Station |

* Cast Iron Stands (Optional) |

|

Forming Speed |

5–15 (M/MIN) |

* Or According To Your Profile Drawings |

|

Rollers’ Material |

GCr 15 |

* Cr12 (Optional) |

|

Cutting System |

Hydraulic Cutting |

* Saw Cutting (Optional) |

|

Frequency Changer Brand |

Yaskawa |

* Siemens (Optional) |

|

PLC Brand |

Panasonic |

* Siemens (Optional) |

|

Power Supply |

380V 50Hz 3ph |

* Or According To Your Requirement |

|

Machine Color |

Industrial Blue |

* Or According To Your Requirement |

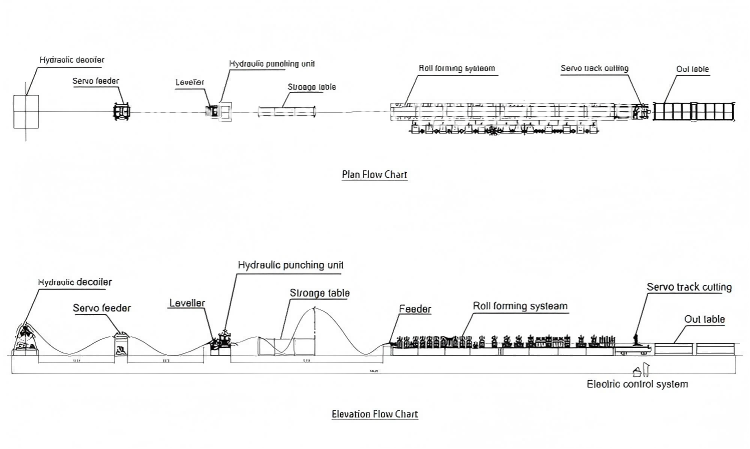

The machine realizes seamless automated operations including uncoiling, servo feeding, punching, roll forming, and cutting, ensuring efficient and consistent production. It handles metal strips precisely, shaping them into standard upright profiles through sequential roller stations—each set of rollers (crafted for gradual bending) guarantees uniform cross-sections and dimensional accuracy, meeting strict storage structure requirements.

As a one-stop solution provider, Xinnuo complements this machine with supporting equipment for pallet racking systems, such as box beam, step beam, and shelf panel roll forming machines. This enables customers to produce all key rack components in-house, optimizing production workflows.

We prioritize customization to fit diverse needs: our professional one-to-one service tailors solutions based on customers’ drawings, tolerance demands, and budgets. With high production efficiency and reliable quality, Xinnuo’s machine ensures perfectly functional upright profiles, supporting cost-effective pallet racking systems—easily configurable for different pallet sizes and forklift types, widely used in warehouses and industrial storage.

Upright roll forming machines are industrial metalworking equipment that mold continuous metal strips into uniform cross-sectional profiles for structural use.

Core advantages and application scenarios