Product Overview

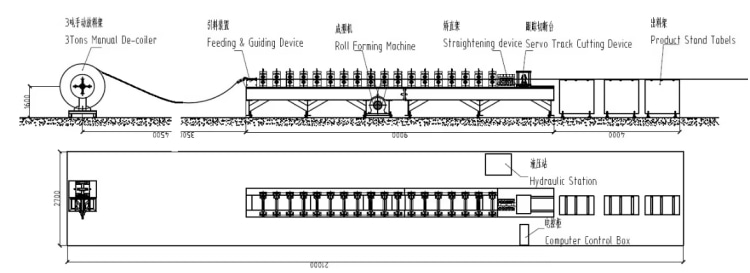

The Metal Shelf Storage Rack Beam Machine is an intelligent and high-performance production equipment for metal shelf beams. It integrates advanced PLC control technology and precision mechanical design to realize the full-automatic production process from raw material uncoiling to finished product cutting. The machine is characterized by high forming precision, fast production speed, and simple operation, which can effectively reduce labor costs and improve production efficiency for manufacturers. It is an ideal choice for storage rack manufacturers pursuing high-quality, high-efficiency, and intelligent production.

Core Technical Specifications

-

Raw material: Cold-rolled steel, Galvanized steel (optional stainless / color-coated steel)

-

Material thickness: 1.5 – 3.0 mm

-

Roller material: GCr15 (or optional Cr12) alloy steel, heat treated (quenched / hardened)

-

Roller hardness: HRC 58 – 62° (depending on heat treatment)

-

Number of forming stations: 16 – 28 stations (profile dependent)

-

Forming (line) speed: 5 – 15 m/min (depending on profile & configuration)

-

Main motor power: 15 – 22 kW (depending on model)

-

Cutting / Shearing system: Hydraulic cutting (or saw-cut); cutting blades made of heat-treated Cr12 / Cr12MoV

-

Control system: PLC control (Siemens / Panasonic / Delta optional) — supports automatic forming, punching, cutting, length & quantity control

-

Decoiler: Manual or hydraulic decoiler (capacity configurable, e.g. 3t–5t)

-

Material width: As per customer’s profile drawing / specification

-

Profile types: Upright rack columns / shelf upright posts / pallet rack uprights / warehouse shelving uprights

-

Power supply / Voltage: 380 V, 50 Hz, three-phase (customizable per customer requirement)

Key Product Advantages

1. Intelligent Automatic Control: Equipped with internationally renowned brand PLC control system, it can automatically complete forming, punching, cutting, length and quantity control. The intelligent system reduces human error and ensures consistent product quality.

2. High-Speed & High-Precision: The 16-28 adjustable forming stations and high-hardness rollers ensure precise forming of shelf beams. The forming speed of 5-15 m/min meets the needs of large-batch production, realizing the balance of speed and precision.

3. Easy Maintenance & Operation: The machine structure is scientific and reasonable, with easy-to-dismantle and maintain components. The humanized operation interface and detailed operation manual enable operators to get started quickly, reducing training costs.

Quality & Safety Assurance

The machine is manufactured in strict accordance with ISO9001:2015 quality management system standards, with complete quality inspection procedures. It has obtained CE certification, ensuring that it meets the safety and quality requirements of global markets. The real-time fault monitoring system can promptly alarm and shut down, ensuring production safety.

Global Service Support

We provide customized pre-sales solutions, professional on-site installation and commissioning, lifelong maintenance guidance, and free software upgrade services. The global logistics and customs clearance team ensures that the equipment is delivered to customers smoothly.

Typical Applications

Widely used in the production of shelf beams for industrial warehouses, logistics distribution centers, commercial supermarkets, cold-chain storage, and other fields, adapting to different load-bearing and storage requirements.