| Technical Specification of Beam Box Roll Forming Machine | |

|---|---|

| Raw Material | |

| Type | Galvanized Metal, Black Sheet Steel |

| Thickness | 1.5-2.0 mm |

| Machine Performance | |

| Speed | 0-15 m/min |

| Size Change | PLC Control, Fully Automatic |

| Uncoiler | |

| Type | Hydraulic |

| Capacity | 5 T |

| Roll Forming Machine | |

| Main Roller Station | 24 |

| Main Drive | Servo Motor |

| Transmission Type | Gearbox |

| Cutting Machine | |

| Cutter Type | Mold Cutter |

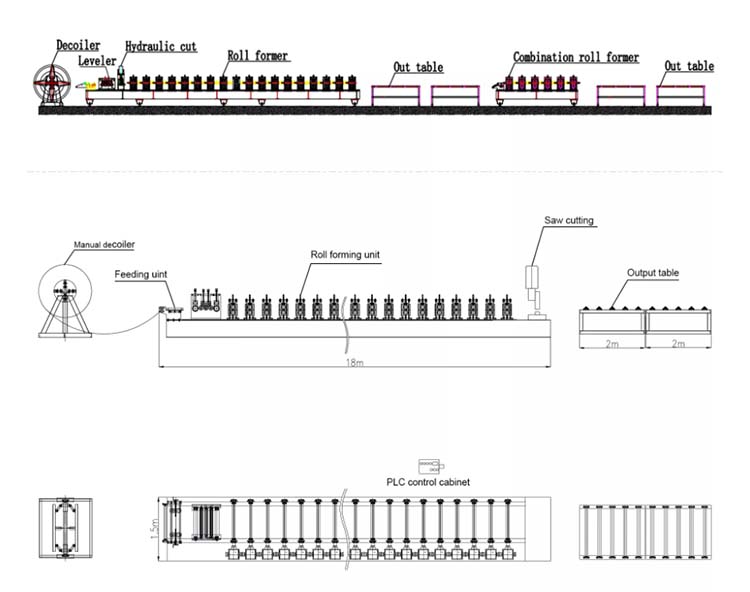

Our Box Beam Roll Forming Machine is a specialized solution designed to produce high-strength storage shelf box beams — also known as cross beams or joist beams — for modern racking and shelving systems. Using a precisely engineered series of rollers, this roll forming machine continuously shapes galvanized steel strips into a closed rectangular “box” section, delivering excellent rigidity and load-bearing capacity.

Once the C-sections are roll formed, a locking or seaming unit locks two pieces together to create a seamless box beam. This automatic locking mechanism improves production efficiency and ensures strong, reliable joints — a critical feature for structural rack beams.

| Technical Specification of Beam Box Roll Forming Machine | |

|---|---|

| Raw Material | |

| Type | Galvanized Metal, Black Sheet Steel |

| Thickness | 1.5-2.0 mm |

| Machine Performance | |

| Speed | 0-15 m/min |

| Size Change | PLC Control, Fully Automatic |

| Uncoiler | |

| Type | Hydraulic |

| Capacity | 5 T |

| Roll Forming Machine | |

| Main Roller Station | 24 |

| Main Drive | Servo Motor |

| Transmission Type | Gearbox |

| Cutting Machine | |

| Cutter Type | Mold Cutter |

Key features of the machine include:

Material compatibility: Cold-rolled steel, galvanized coil, stainless steel, PPGI, and more.

Thickness range: Typically 1.5–3.0 mm, depending on the specification.

Forming stations: Multiple roll stands (e.g., 15–20) to precisely shape the beam.

Control system: PLC-controlled, with automatic size change options for both beam width and height.

Cutting: Hydraulic cutter or flying shear for accurate, burr-free cuts.

Drive system: Robust gearbox drive or chain, depending on configuration.

Box beams produced by a box beam roll forming machine are highly versatile. In construction, they serve as major load-bearing elements in building frames, bridges, and infrastructure, offering rigidity and structural stability. In industrial racking and shelving systems, these box beams act as horizontal supports for heavy-duty storage units and pallets — they are ideal for warehouse racks, distribution centers, and manufacturing facilities.

In material-handling equipment, box beams are used in cranes, conveyors, and lifting mechanisms, providing reliable structural support for moving heavy loads. In the automotive industry, they are employed in chassis and vehicle frames, contributing to crashworthiness and structural integrity. Box beams also find practical use in agricultural machinery — such as trailers and heavy equipment — where strength and durability are essential.

Thanks to their closed-section design, box beams combine high load-bearing capacity with excellent torsional resistance, making them suitable for demanding engineering tasks across multiple industries.