| Section | Key Highlights |

|---|---|

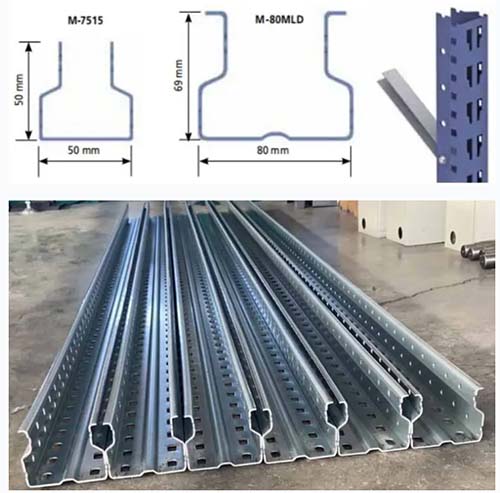

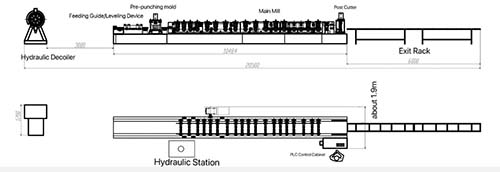

| Product Name | High Quality Rack Upright Roll Forming Machine |

| Core Design Features | Unique design concept; advanced roller system; ultra-smooth roller surface reduces friction; improves production efficiency |

| High-Precision Molds | Made from special high-hardness wear-resistant materials; ±0.1mm precision control ensures dimensional stability over long production cycles |

| Applicable Materials | Carbon steel, stainless steel, aluminum alloy |

| Application Scenarios | Heavy-duty warehouse racks, corrosion-resistant racks, lightweight aluminum shelving, various upright rack specifications |

| Quality & Stability | Strict machining and inspection; high-strength structural components; excellent fatigue and corrosion resistance; low vibration and noise during operation |

| Pre-Sales Service | Technical consultation; customized solutions; production line planning advice |

| Installation & Commissioning | On-site installation; operator training on operation and maintenance |

| After-Sales Service | Fast response support; remote troubleshooting; on-site technical assistance; spare parts availability |

Our High Quality Rack Upright Roll Forming Machine represents the perfect combination of innovation, precision, and durability. Designed with a unique roller system, it ensures ultra-smooth sheet forming with minimal friction, greatly improving production efficiency. The precision-engineered molds, made from wear-resistant special materials, maintain ±0.1mm dimensional accuracy even during long production cycles — ensuring stable quality and eliminating defects caused by size deviations.

The High Quality Rack Upright Roll Forming Machine delivers strong adaptability for various metal materials such as carbon steel, stainless steel, and aluminum alloy. It automatically adjusts forming parameters according to material characteristics to guarantee consistent performance. Whether producing heavy-duty warehouse shelves, corrosion-resistant stainless steel racks, or lightweight aluminum systems, this machine provides reliable and efficient forming solutions to meet different market needs.

| Section | Key Highlights |

|---|---|

| Product Name | High Quality Rack Upright Roll Forming Machine |

| Core Design Features | Unique design concept; advanced roller system; ultra-smooth roller surface reduces friction; improves production efficiency |

| High-Precision Molds | Made from special high-hardness wear-resistant materials; ±0.1mm precision control ensures dimensional stability over long production cycles |

| Applicable Materials | Carbon steel, stainless steel, aluminum alloy |

| Application Scenarios | Heavy-duty warehouse racks, corrosion-resistant racks, lightweight aluminum shelving, various upright rack specifications |

| Quality & Stability | Strict machining and inspection; high-strength structural components; excellent fatigue and corrosion resistance; low vibration and noise during operation |

| Pre-Sales Service | Technical consultation; customized solutions; production line planning advice |

| Installation & Commissioning | On-site installation; operator training on operation and maintenance |

| After-Sales Service | Fast response support; remote troubleshooting; on-site technical assistance; spare parts availability |

Manufactured under strict quality control, every component is precisely processed and tested to ensure long-term stability. High-strength materials are used in key parts like the transmission and support structures, providing exceptional resistance to fatigue and corrosion. Its optimized mechanical design minimizes vibration and noise, allowing continuous, stable operation even under high workloads — reducing maintenance costs and extending equipment lifespan.

We offer comprehensive technical consultation, installation, and after-sales service. Before purchase, our experienced engineers provide customized solutions based on your production requirements. During installation, our team offers on-site training covering operation and maintenance to ensure your operators’ full proficiency. Post-installation, we deliver fast and reliable after-sales support with readily available spare parts and remote troubleshooting.