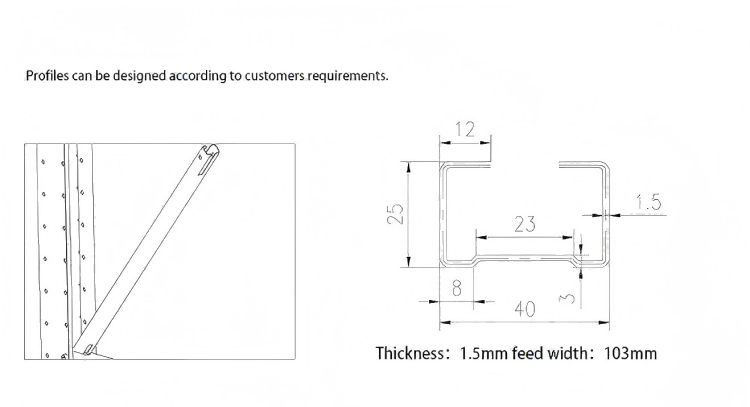

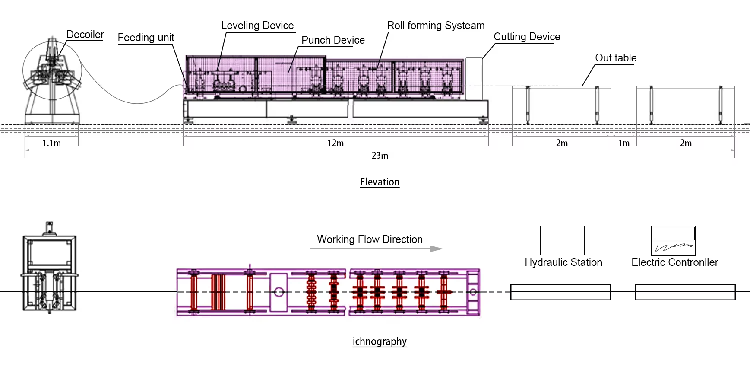

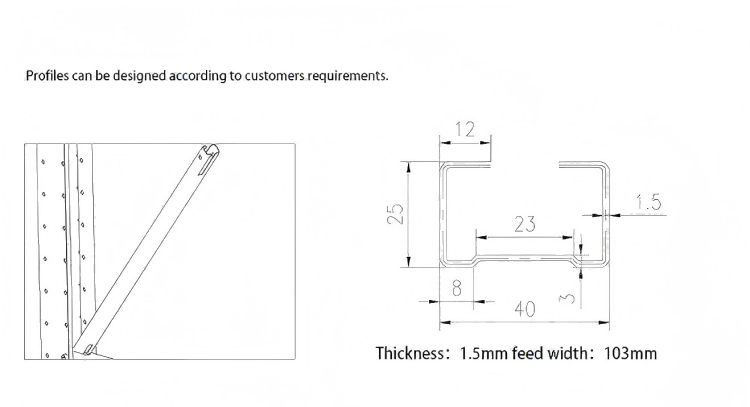

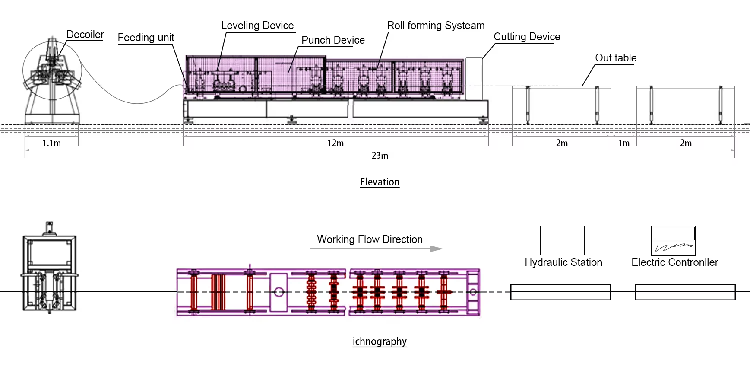

Designed to streamline the production of C-shaped rack uprights for storage and bracing applications, this roll forming machine stands out for its precision, durability, and adaptability to diverse production environments. It supports multiple machinable materials, including Galvanized Coil (1.5-1.8MM thickness, customizable), PPGI, PPGL, Cold-rolled Steel and Carbon Steel, allowing manufacturers to produce rack components for various industries, from logistics to retail warehousing. The machine is optimized for materials with Yield Strength of 250 - 350 Mpa and Tensil Stress of 350 Mpa-500 Mpa, ensuring the final products can withstand heavy loads and harsh working conditions.

Key performance parameters include a Nominal Forming Speed of 10-15 M/Min (adjustable per customer needs) and around 14 Forming Stations (tailored to specific profile drawings), balancing speed and accuracy for optimal productivity. The decoiling system offers a Manual Decoiler as standard, with an optional Hydraulic Decoiler for automated material handling. The driving system features a standard Chain Drive for reliable power transmission, with an optional Gearbox Drive for enhanced control in high-precision forming scenarios. The machine’s structure is Steel Plates Welded for cost-effectiveness and robustness, with Cast Iron Stands available as an upgrade for reduced deformation during long-term use.

|

C Bracing Section Roll Forming Machine

|

|

Machinable Material

|

A) Galvanized Coil

|

Thickness(MM):1.5-1.8 as per customer

|

|

|

B) PPGI,PPGL

|

|

|

|

C) Cold-rolled Steel

|

|

|

|

D) Carbon Steel

|

|

|

Yield Strength

|

250 - 350 Mpa

|

|

Tensil Stress

|

350 Mpa-500 Mpa

|

|

Nominal Forming Speed(M/Min)

|

10-15

|

* Or According To Your Requirment

|

|

Forming Station

|

About 14

|

* According To Your Profile Drawings

|

|

Decoiler

|

Manual Decoiler

|

* Hydraulic Decoiler (Optional)

|

|

Driving System

|

Chain Drive

|

* Gearbox Drive (Optional)

|

|

Machine Structure

|

Steel Plates Welded

|

* Cast Iron Stands (Optional)

|

|

Rollers’ Material

|

GCr 15

|

* Cr12Mov (Optional)

|

|

Cutting System

|

Hydraulic Pre-cut

|

|

Punching System

|

Hydraulic Punching

|

|

Frequency Changer Brand

|

Yaskawa

|

* Siemens (Optional)

|

|

Power Supply

|

380V 50Hz

|

* Or According To Your Requirment

|

|

Machine Color

|

Industrial Blue

|

* Or According To Your Requirment

|

Roller durability is ensured by GCr 15 material (optional Cr12Mov rollers for extended service life in heavy-duty production), maintaining consistent forming quality over thousands of cycles. The integrated Hydraulic Pre-cut System and Hydraulic Punching System provide precise, efficient shaping, reducing material waste and production time. A Yaskawa frequency changer ensures stable speed regulation, with Siemens as an optional alternative for compatibility with existing factory control systems. The machine is configured for 380V 50Hz power supply (customizable) and finished in industrial blue, with color customization options to meet your specific requirements.