Product Overview

As a high-end customized solution, this machine adapts to diverse shelf beam production needs. It offers flexible configuration of core components, fitting special-shaped beam profiles and regional production standards for global premium storage equipment manufacturers.

Core Technical Specifications

-

Raw material: Cold-rolled steel, Galvanized steel (optional stainless / color-coated steel)

-

Material thickness: 1.5 – 3.0 mm

-

Roller material: GCr15 (or optional Cr12) alloy steel, heat treated (quenched / hardened)

-

Roller hardness: HRC 58 – 62° (depending on heat treatment)

-

Number of forming stations: 16 – 28 stations (profile dependent)

-

Forming (line) speed: 5 – 15 m/min (depending on profile & configuration)

-

Main motor power: 15 – 22 kW (depending on model)

-

Cutting / Shearing system: Hydraulic cutting (or saw-cut); cutting blades made of heat-treated Cr12 / Cr12MoV

-

Control system: PLC control (Siemens / Panasonic / Delta optional) — supports automatic forming, punching, cutting, length & quantity control

-

Decoiler: Manual or hydraulic decoiler (capacity configurable, e.g. 3t–5t)

-

Material width: As per customer’s profile drawing / specification

-

Power supply / Voltage: 380 V, 50 Hz, three-phase (customizable per customer requirement)

|

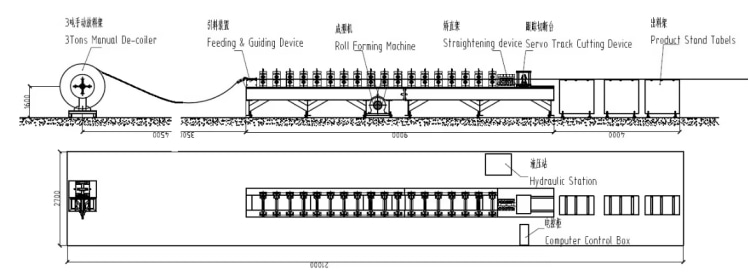

Automatic Box Beam Roll Forming Line

|

|

Machinable Material

|

A) Galvanized Coil

|

Thickness(MM):1.5-3.0 as per customer

|

|

|

B) Cold/Hot-rolled Steel

|

|

|

|

C) Carbon Steel

|

|

|

Yield Strength

|

250 - 350 Mpa

|

|

Tensil Stress

|

350 Mpa-500 Mpa

|

|

Nominal Forming Speed(M/Min)

|

10-20

|

* Or According To Your Requirment

|

|

Forming Station

|

18-20

|

* According To Your Profile Drawings

|

|

Decoiler

|

Manual Decoiler

|

* Hydraulic Decoiler (Optional)

|

|

Driving System

|

Chain Drive

|

* Gearbox Drive (Optional)

|

|

Machine Structure

|

Steel Plates Welded

|

* Cast Iron Stands (Optional)

|

|

Rollers’ Material

|

GCr 15

|

* Cr12Mov (Optional)

|

|

Cutting System

|

Hydraulic Cut

|

* Saw Cut (Optional)

|

|

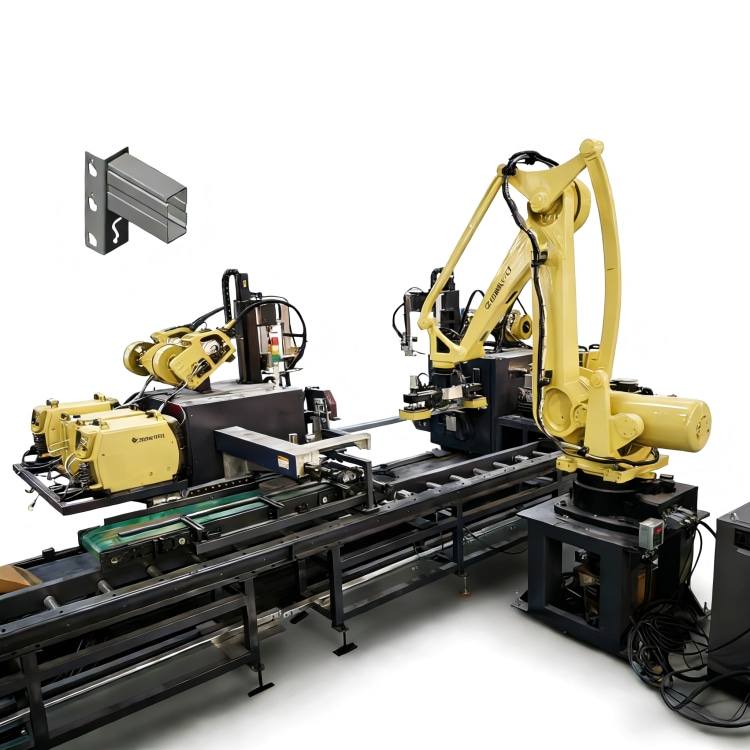

Boxing Unit

|

By Chain

|

* By Gearbox (Optional)

|

|

Welding Efficiency

|

Specification 50*100±25 seconds/pcs,

Specification 50*120-140±30 seconds/pcs,

Specification 50*160±35 seconds/pcs (Except for beams with unilateral error of >1.5mm)

|

|

Welding &Stacking Process

|

Stack the hanging pieces in order on the automatic hanging piece feeding platform,then input the signal,the machine starts to automatically load the hanging pieces,and at the same time,the robot automatically grabs the crossbeam to the specified position of the machine platform,starts welding,first welds the two sides,rotates 90 degrees and then welds the two sides to complete the welding,rotates to another station,and the robot takes the material to the finished product stacking,and the robot takes the material again,and the above actions are repeated. All the above actions are controlled and operated by the dedicated system for the crossbeam automatic line

|

|

Machine Color

|

Industrial Blue

|

* Or According To Your Requirment

|

Key Product Advantages

1. Flexible Customization: Customize material width, roller type and PLC brand per drawings, fitting special-shaped beams for high-end and intelligent shelves.

2. Durable Wear-Resistant Components: Heat-treated alloy steel rollers and cutting blades ensure low wear, adapting to small-batch and multi-specification customized production.

3. Multi-Profile Adaptation: Adjustable stations and speed fit various beam specifications, meeting personalized load-bearing and assembly requirements.

Quality & Safety Assurance

Certified by SGS and TUV Rheinland, the machine undergoes full-process quality inspection, ensuring compliance with global high-end storage equipment standards.

Global Service Support

Offer one-stop services including customized solution design, on-site debugging, maintenance training and lifelong accessory supply for global manufacturers.

Typical Applications

Suitable for premium beams of heavy-duty industrial racks, intelligent logistics racks, special environment storage shelves and high-end commercial display racks.