Xinnuo Rack Shelf Roll Forming Machine: The Backbone of Efficient Storage Production

In the age of intelligent logistics and expanding e-commerce, high-quality rack shelves have become the cornerstone of efficient warehouse management—determining space utilization, load-bearing safety, and operational productivity. Xinnuo’s Rack Shelf Roll Forming Machine is engineered to be the ultimate production solution for these critical storage components, leveraging 25+ years of specialized roll forming expertise and ISO 9001, CE certifications to serve manufacturers across 60+ countries. From the dense retail shelving in European supermarkets to the heavy-duty pallet racks in North American industrial warehouses, this machine powers the production of reliable, durable rack shelves that meet the diverse demands of global storage markets.

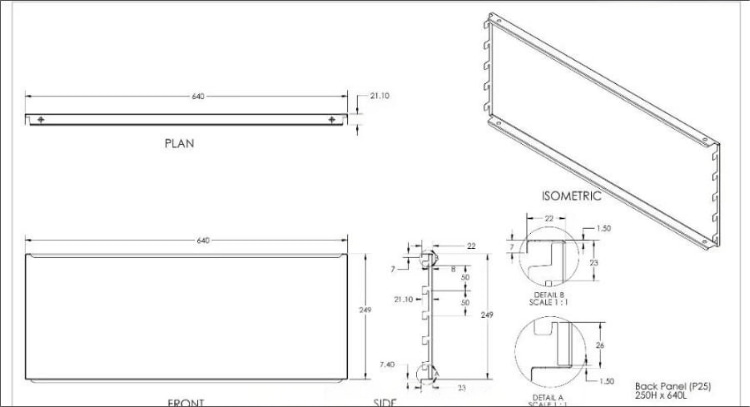

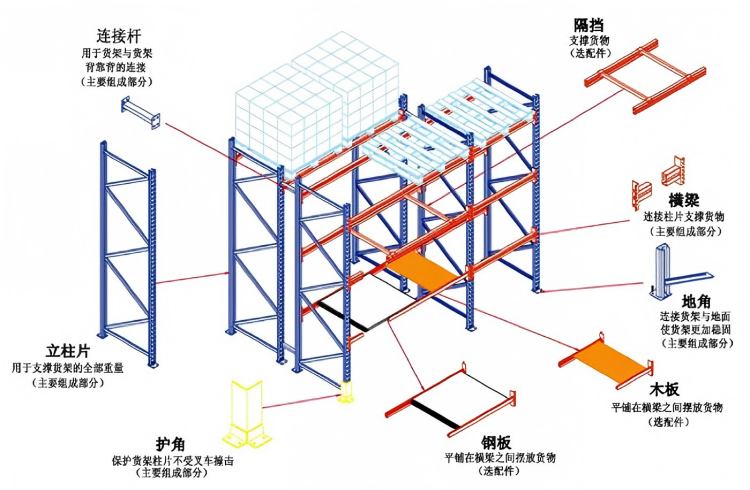

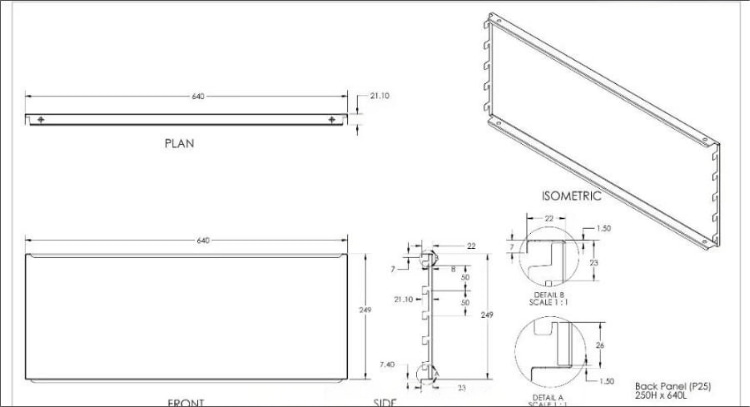

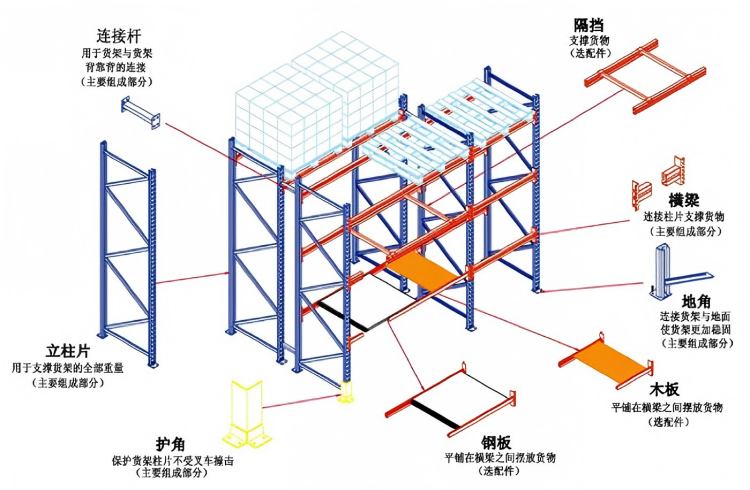

What distinguishes this machine from generic forming equipment is its unparalleled precision and adaptability to the unique requirements of rack shelf production. Rack shelves, whether for light-duty cosmetic displays or heavy-duty automotive parts storage, demand consistent profiles, smooth edges, and robust structural integrity. Xinnuo’s machine excels in this regard by processing a wide range of materials—0.8-3.5mm thick galvanized steel, carbon steel, cold-rolled steel, and even colored steel coils—each transformed into high-quality shelf components with dimensional tolerance of ±0.2mm. This precision ensures that every shelf produced fits seamlessly with uprights and beams, eliminating assembly delays and enhancing the overall stability of the rack system, which is crucial for withstanding daily warehouse operations, including forklift impacts and heavy load stacking.

Efficiency is a core design principle, addressing the production bottlenecks that modern manufacturers face. Equipped with a Siemens PLC control system and a 10-inch color touchscreen HMI, the machine automates the entire production workflow from start to finish. A 6-ton hydraulic decoiler with automatic coil centering feeds materials stably, preventing material waste caused by misalignment. A precision leveling unit eliminates coil warpage, ensuring flat, uniform blanks for forming. A high-speed punching module creates accurate mounting holes—essential for quick and secure shelf installation—while a 24-roller forming section shapes the material in one seamless pass, avoiding the deformities common in multi-step processes. Finally, a servo-driven flying cutting device trims shelves to exact lengths (0.5-8m) without stopping production, boosting output to 12-20 meters per minute. This full automation reduces labor needs from 3 workers to 1, cutting labor costs by 70% and enabling manufacturers to meet large orders with shorter lead times.

Customization is another key strength, designed to cater to the diverse needs of the storage industry. Xinnuo’s R&D team of 50+ engineers works closely with clients to tailor every aspect of the machine’s output—from shelf profiles (such as step beams, decking boards, and shelf brackets) to punching patterns and surface finishes. Whether a client needs anti-slip shelf decks for food and beverage warehouses, corrosion-resistant shelves for cold-chain storage, or custom-sized shelves for modular retail displays, the machine can be programmed to produce 150+ unique designs with minimal setup time (under 5 minutes). This flexibility allows manufacturers to expand their product portfolios, target niche markets, and stay ahead of competitors offering one-size-fits-all solutions.

For manufacturers seeking a reliable, efficient, and flexible solution for rack shelf production, Xinnuo’s Rack Shelf Roll Forming Machine is more than just equipment—it’s a partner that enhances product quality, streamlines operations, and strengthens competitive advantage. Whether you’re a small-scale shelving manufacturer or a large industrial supplier, this machine empowers you to produce rack shelves that exceed customer expectations and drive business growth in the global storage market.