Product Description

Product Overview

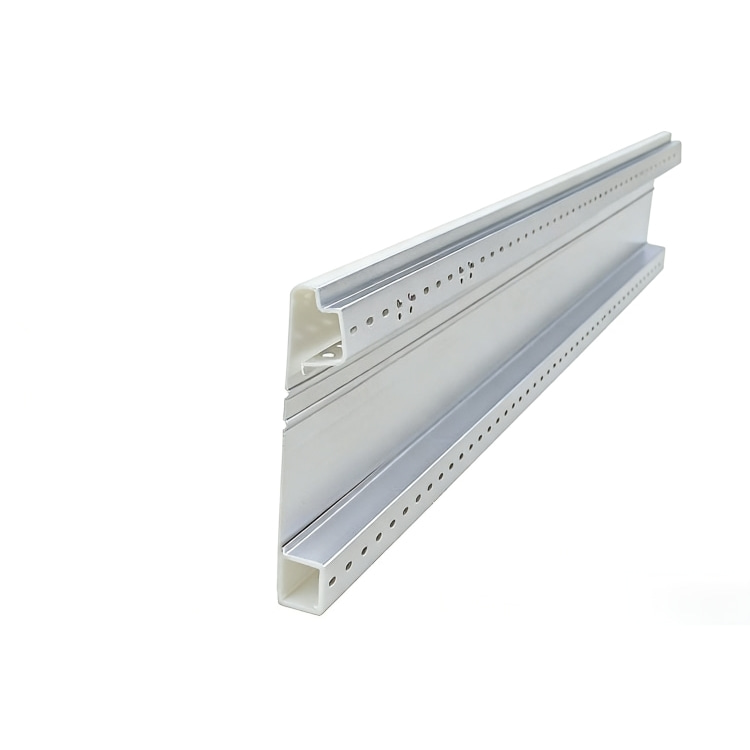

Our Shelf Side Panel Forming Line is a fully automated production solution tailored for manufacturing high-strength, precision side panels—key structural components for warehouse racks, retail shelves, and logistics storage systems. From the reinforced integral steel frame to the intelligent centralized control system, every module is engineered to deliver stable batch forming, excellent edge quality, and high adaptability, serving as a core production line for shelving manufacturers in 80+ countries.

The forming line is equipped with ultra-wear-resistant roller sets made from imported Japanese SUJ2 alloy steel. After vacuum quenching and precision grinding, the roller surface hardness reaches HRC63, ensuring deformation-free forming when processing 1.0–3.0 mm hot-dip galvanized steel, cold-rolled steel, and zinc-aluminum alloy coated steel. Its quick-change roller system enables mold replacement within 18 minutes, supporting side panels with widths ranging from 300mm to 900mm to match diverse shelf designs.

Technical Advantages

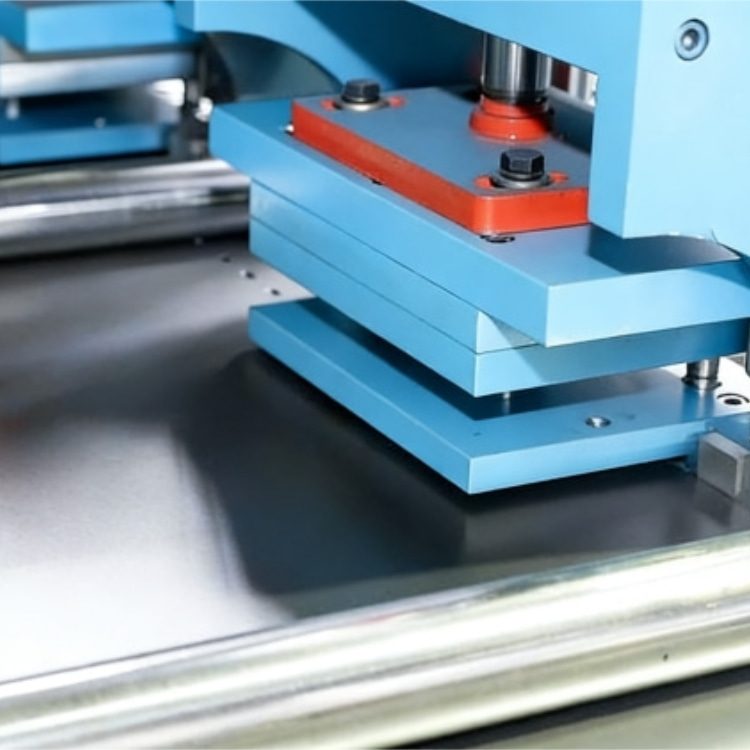

Precision-Controlled Forming System: Adopting Delta high-torque servo motors and Siemens S7-1500 PLC control, the line maintains side panel dimensional accuracy within ±0.2 mm and edge straightness below 0.3 mm/m, fully complying with GB/T 27924-2011 and ANSI MH16.1 standards.

Integrated Full-Automation Process: The one-stop workflow of automatic material feeding, pre-leveling, forming, punching, edge deburring, and servo cutting eliminates secondary processing, reducing total production time by 55% and lowering material waste to less than 1.0%.

High-Scale Productivity: A single forming line can produce up to 180 sets of shelf side panels per day, which is 4 times the output of traditional manual production lines, efficiently meeting large-order demands from retail chains and logistics enterprises.

Safety & Quality Assurance

To ensure operator safety and product consistency, the line is equipped with five-group infrared safety gratings and emergency stop buttons that trigger shutdown within 0.05 seconds. A high-definition visual inspection system monitors panel surface defects, hole position accuracy, and forming angle in real-time, automatically sorting non-conforming products. The finished side panels can stably bear 1200 kg per square meter, ensuring structural safety of the whole shelf.

Material Compatibility

The forming line supports a variety of high-performance materials, including 1.0–3.0 mm hot-dip galvanized steel (zinc layer ≥ 120g/m²), cold-rolled steel, and color-coated steel sheets. Through adaptive roller pressure control (adjustable within 6–18 MPa) and constant-temperature cooling technology, it perfectly preserves the material’s anti-corrosion coating and structural toughness, making finished side panels suitable for dry warehouses, cold storage, and outdoor logistics platforms.

One-Stop Global Service

We provide comprehensive service solutions covering the entire production line lifecycle:

Pre-sales consulting: Multilingual technical support (English, Spanish, Russian, Arabic, Korean), on-site factory layout planning, and side panel specification optimization based on local market demands.

Sales support: Customized packaging for large-scale equipment, professional customs clearance for industrial lines, on-site installation and commissioning, and 5-day in-depth training for operation and maintenance teams.

After-sales service: 24/7 on-call technical engineers, 30-month warranty for core components (rollers, servo motors, PLC), lifetime maintenance guidance, and free system upgrades for 5 years.

Certifications

CE | ISO9001 | SGS | TUV | ANSI MH16.1 | DIN EN 15512

Typical Applications

Side panel production for warehouse storage racks

Reinforced side panel manufacturing for retail and supermarket shelves

Corrosion-resistant side panels for cold-chain and food storage racks

Lightweight yet sturdy side panels for convenience store and pharmacy shelves