Product Description

Product Overview

Our Shelves Roll Forming Machine is a professional cold-forming equipment tailored for manufacturing high-precision shelf components (uprights, beams, panels) — the core of warehouse storage, retail display, and home storage systems. From the anti-vibration welded steel frame to the smart touch-control system, every component is engineered to deliver stable forming quality, fast specification switching, and low maintenance cost, serving as a core production pillar for shelving manufacturers in 90+ countries.

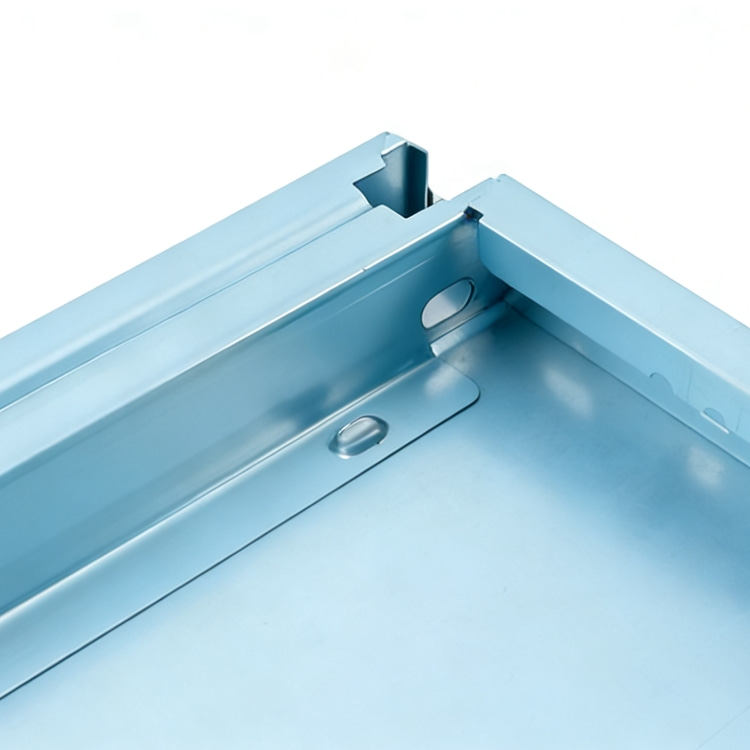

The machine is equipped with high-wear roller sets made from imported German 1.2344 alloy steel. After double quenching and precision grinding, the roller surface hardness reaches HRC65, ensuring consistent forming when processing 1.0–3.2 mm hot-dip galvanized steel, cold-rolled steel, and color-coated steel sheets. Its quick-change roller mechanism enables mold replacement within 22 minutes, supporting shelf components with heights from 800mm to 5000mm and widths from 300mm to 1000mm.

Technical Advantages

Precision Forming Control: Adopting Yaskawa high-precision servo motors and Siemens S7-1200 PLC control, the machine maintains component dimensional accuracy within ±0.25 mm and surface flatness below 0.4 mm/m, fully complying with GB/T 27924-2011 and ANSI MH16.1 standards.

Integrated Efficient Process: The one-stop workflow of automatic material feeding, pre-leveling, forming, multi-station punching, and servo cutting eliminates secondary processing, reducing total production time by 50% and lowering material waste to less than 1.3%.

Stable Productivity: A single machine can produce up to 150 sets of shelf components per day, which is 3 times the output of traditional semi-automatic equipment, effectively meeting the diverse order demands of retail and logistics industries.

Safety & Quality Assurance

To ensure operator safety and product consistency, the machine is equipped with dual infrared safety gratings and emergency stop buttons that trigger shutdown within 0.06 seconds. A laser inspection system real-time monitors component thickness, edge straightness, and hole position accuracy, automatically rejecting non-conforming products. The finished components can stably bear 1200 kg per layer, ensuring the structural safety of the whole shelf.

Material Compatibility

The machine supports a variety of mainstream materials, including 1.0–3.2 mm hot-dip galvanized steel (zinc layer thickness 80-180g/m²), cold-rolled steel, and polyester color-coated steel. Through adaptive roller pressure control (adjustable within 5–20 MPa) and constant-temperature cooling, it preserves the material’s surface integrity and anti-corrosion performance, making finished shelves suitable for dry warehouses, cold storage, and home environments.

One-Stop Global Service

We provide comprehensive service solutions covering the entire equipment lifecycle:

Pre-sales consulting: Multilingual technical support (English, Spanish, Russian, Arabic, Japanese), on-demand production line planning, and component specification optimization based on local market needs.

Sales support: Professional customs clearance, international shipping (sea/air/land), on-site installation and commissioning, as well as 4-day systematic training for operation and maintenance teams.

After-sales service: 24/7 online technical assistance via video call, 30-month warranty for core components (rollers, servo motors, PLC), lifetime maintenance guidance, and free software upgrades for 4 years.

Certifications

CE | ISO9001 | SGS | TUV | ANSI MH16.1 | BS EN 15512

Typical Applications

Shelf component production for warehouse storage racks

Display shelf manufacturing for supermarkets and convenience stores

Corrosion-resistant shelf production for cold-chain and food storage

Lightweight shelf components for home and office storage systems