Product Description

Product Overview

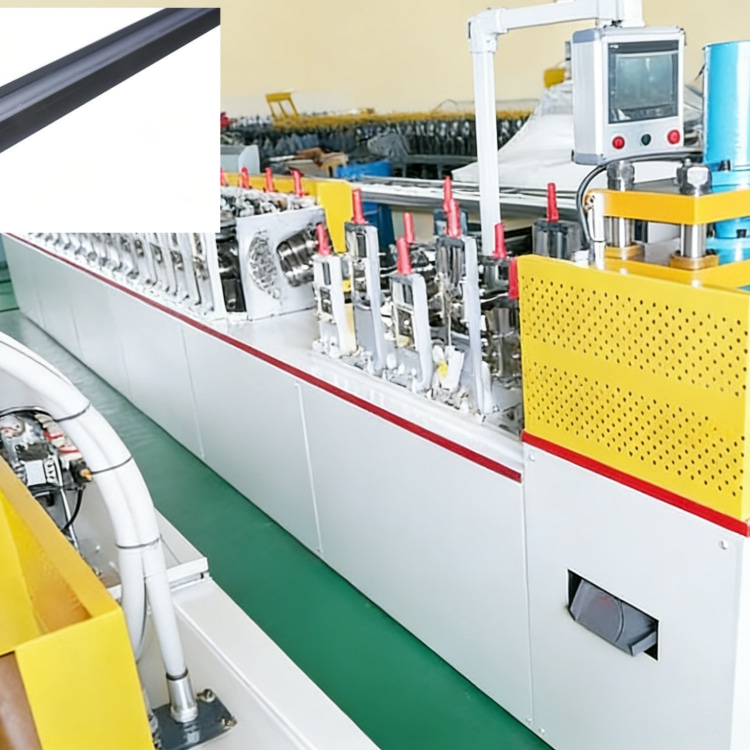

Our Z Beam Roll Forming Machine is a specialized cold-forming equipment engineered exclusively for manufacturing high-strength Z-shaped beams—core load-bearing components of heavy-duty shelves, warehouse racks, and logistics storage systems. From the integral forged steel frame to the CNC intelligent control module, every part is precision-tailored to deliver high-strength forming, 精准尺寸控制, and 24/7 continuous operation, serving as a production backbone for shelf manufacturers in 100+ countries.

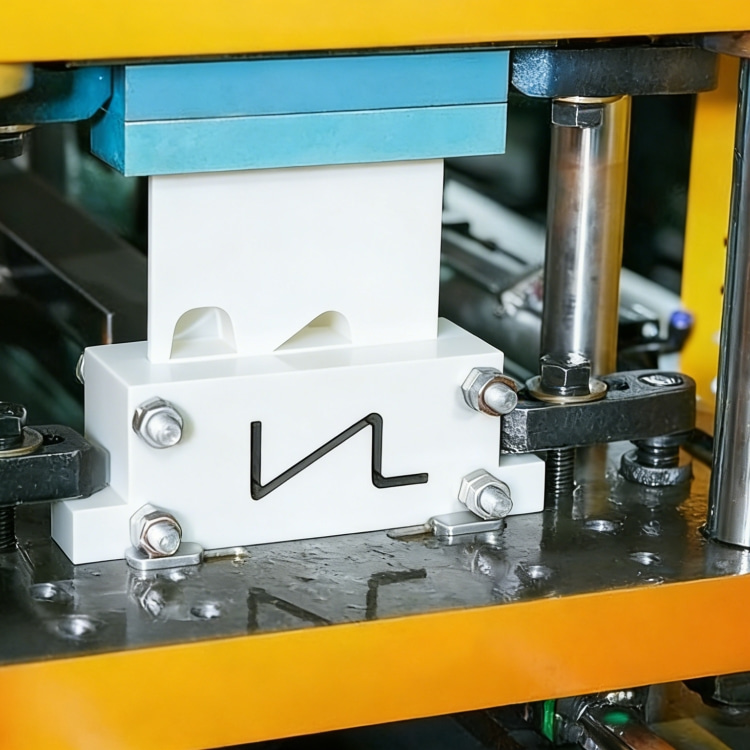

The machine features ultra-wear-resistant roller sets crafted from imported Swedish SS2343 alloy steel. After double quenching and precision grinding, the roller surface hardness reaches HRC65, ensuring deformation-free forming when processing1.5–4.0 mm Q355B high-strength carbon steel, hot-dip galvanized steel, and zinc-aluminum-magnesium coated steel. Its hydraulic quick-change roller system enables mold replacement within 18 minutes, supporting Z beams with widths from 400mm to 1200mm and heights from 150mm to 500mm—perfectly matching mainstream shelf specifications.

Technical Advantages

High-Precision Dimensional Control: Equipped with Panasonic high-torque servo motors and Siemens S7-1500 PLC, the machine maintains Z beam dimensional accuracy within ±0.2 mm and flange straightness below 0.35 mm/m, fully complying with GB/T 27924-2011 and ANSI MH16.3 heavy-duty shelf standards.

Integrated Z-Beam Forming Process: The one-stop workflow covers automatic material uncoiling, pre-leveling, multi-pass Z-shape forming, flange trimming, and servo precision cutting—eliminating secondary processing of beam ends. This reduces production time by 60% and lowers material waste to less than 1.0%.

Industrial-Grade Productivity: A single machine can produce up to140 sets of Z beams per day, which is 3.5 times the output of traditional semi-automatic forming equipment, efficiently meeting bulk orders for logistics warehouse shelf projects.

Safety & Quality Assurance

Aiming at heavy-duty production scenarios, the machine is equipped with six-group infrared safety gratings and dual emergency stop systems that achieve shutdown response within 0.04 seconds to protect operators. A 3D laser inspection system real-time monitors Z beam flange width, web height, and weld quality, automatically rejecting products failing the minimum 2000 kg per beam load requirement—ensuring consistent batch quality.

Material Compatibility

The machine specializes in processing high-strength materials for load-bearing beams, including1.5–4.0 mm Q355B/Q420 carbon steel, hot-dip galvanized steel (zinc layer ≥ 180g/m²), and weather-resistant steel. Through adaptive roller pressure control (adjustable within 8–25 MPa) and circulating water cooling, it preserves material toughness and anti-corrosion performance, making finished Z beams suitable for outdoor stockyards, humid workshops, and chemical storage facilities.

One-Stop Global Service

We provide professional services tailored for industrial equipment users:

Pre-sales consulting: Multilingual technical support (English, German, Russian, Portuguese), on-site factory layout planning, and Z beam load-bearing performance optimization for special scenarios (e.g., explosion-proof warehouses).

Sales support: Heavy-equipment dedicated packaging, industrial machinery customs clearance agency, on-site installation & commissioning, and 7-day in-depth training for operation and maintenance teams.

After-sales service: 24/7 on-call technical engineers (key regions respond within 48 hours), 36-month warranty for core components (rollers, servo motors, hydraulic pumps), lifetime maintenance guidance, and free system upgrades for 5 years.

Certifications

CE | ISO9001 | SGS | TUV | ANSI MH16.3 | GB/T 27924-2011 | DIN EN 15512

Typical Applications

Z beam production for heavy-duty industrial warehouse shelves

High-load Z beam manufacturing for logistics center racks

Corrosion-resistant Z beams for chemical and cold-chain storage racks

Specialized Z beams for automotive and mining equipment storage shelves