| Parameter | Specification |

|---|---|

| Raw material | Cold-rolled steel, Galvanized steel (optional customized material) |

| Material thickness | 1.5 – 3.0 mm (some models support 1.2–3.2 mm or 1.5–3.5 mm) |

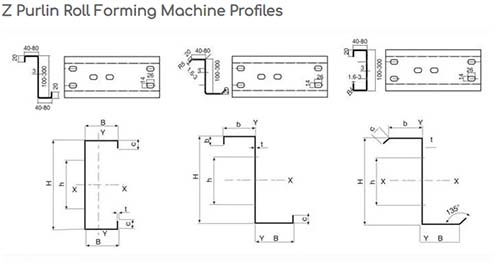

| Profile size (Z-purlin) | Web/height approx. 120–300 mm; flange & lip size customizable (e.g. flange 40–80 mm, lip 10–20 mm) |

| Forming speed | 12 – 25 m/min (typical), up to 30 m/min (depending on configuration) |

| Size-change type | manual (by spacer) or automatic size adjustment (via PLC/servo, 2–5 min change) |

| Roller material | GCr15 bearing steel, quenched & hardened |

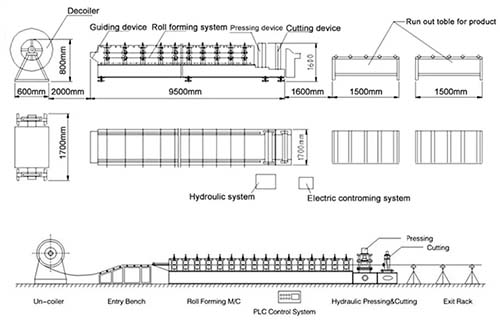

| Cutting / Punching | Hydraulic cutting; optional inline punching for holes/slots (web or flange) |

| Control system | PLC + HMI touchscreen + inverter + encoder — supports automatic length, punch, cut, mold change |

| Uncoiler | manual or hydraulic uncoiler; coil capacity typically 3–5 tons |

| Power supply | 380 V, 3-phase, 50/60 Hz (customizable per client’s requirement) |

Our Z purlin roll forming machine is designed to deliver high-efficiency, flexible production of Z-shaped steel purlins for roofing, wall and structural applications. Whether you need manual size change or automatic size change (2–5 minutes), this machine adapts to your requirements, offering reliable performance for a wide range of materials and sizes.

Dual size-change types: manually adjustable or fully automatic size change within 2–5 minutes, suitable for varying production demands.

High forming speed: Z purlin roll forming machine can run at up to 0–30 m/min, enabling fast production cycles for small or large batches.

Online punching & cutting: integrated punching and cutting mechanisms allow profile production and hole punching in one pass — saving time and reducing secondary processing.

Flexible spacer widths: supports spacers of 10 mm, 20 mm, 40 mm, and 60 mm, enabling varied lip/wing widths to meet different structural specifications.

Wide export & global service capability: we have exported Z purlin roll forming machines to over 50 countries, demonstrating global reliability and experience.

Industry-leading warranty & support: provided with among the best warranty terms in the industry; full support for customization (material, design, language, etc.).

Roofing sheet length is counted by encoder for precise length measurement.

Rollers are hard-chromed to ensure durability and prevent damage to paint/coating.

Hydraulic cutting blades are tested thoroughly to ensure crash-free cutting — even cutting paper without damage, ensuring clean and precise metal cuts.

Easy to operate: simply input the required length and quantity via PLC interface; the machine handles the rest.

Warranty up to 24 months, with 24/7 online service support.

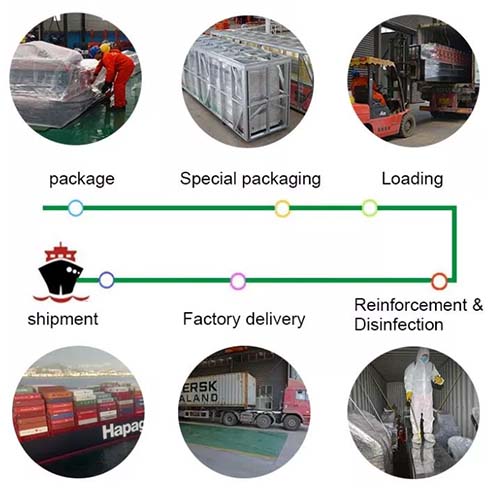

Comprehensive delivery package: user manual, wiring drawing, PDF documentation included. Factory testing ensures all wires are correctly marked before shipping.

If buyers are unable to visit the factory, we provide installation and operation videos, and remote guidance. On-site technician support is also available upon request (buyer arranges travel/hotel/salary).

| Parameter | Specification |

|---|---|

| Raw material | Cold-rolled steel, Galvanized steel (optional customized material) |

| Material thickness | 1.5 – 3.0 mm (some models support 1.2–3.2 mm or 1.5–3.5 mm) |

| Profile size (Z-purlin) | Web/height approx. 120–300 mm; flange & lip size customizable (e.g. flange 40–80 mm, lip 10–20 mm) |

| Forming speed | 12 – 25 m/min (typical), up to 30 m/min (depending on configuration) |

| Size-change type | manual (by spacer) or automatic size adjustment (via PLC/servo, 2–5 min change) |

| Roller material | GCr15 bearing steel, quenched & hardened |

| Cutting / Punching | Hydraulic cutting; optional inline punching for holes/slots (web or flange) |

| Control system | PLC + HMI touchscreen + inverter + encoder — supports automatic length, punch, cut, mold change |

| Uncoiler | manual or hydraulic uncoiler; coil capacity typically 3–5 tons |

| Power supply | 380 V, 3-phase, 50/60 Hz (customizable per client’s requirement) |

This Z purlin roll forming machine is ideal for manufacturing steel roof purlins, structural wall supports, warehouse roofing, factory buildings, workshop sheds, agricultural buildings, storage facilities, and other steel-structure constructions.

We offer a fully customizable solution — from material selection to design configuration — to meet your exact production needs. Whether it's manual or automatic size adjustment, standard or customized spacer widths, different coating materials or languages, we can deliver. With professional global export experience and robust warranty and after-sales support, we ensure you receive a reliable and long-lasting roll forming solution.