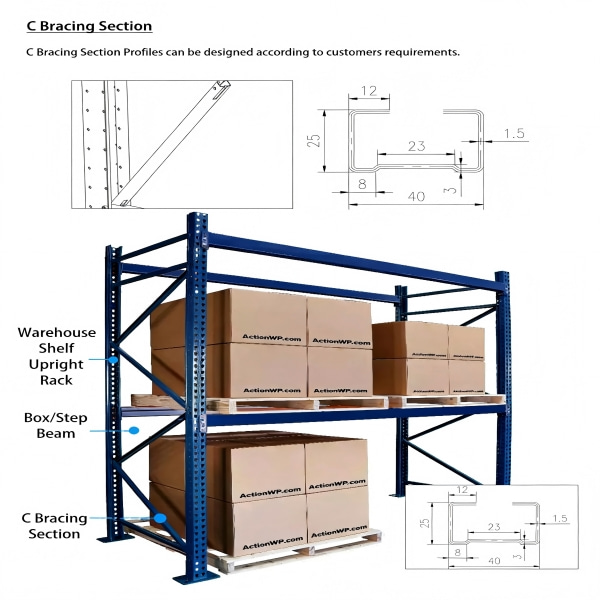

C Bracing Section Roll Forming Machine also named C beam roll forming machine is developed to produce C beam which is for supporting the uprights rack and shelving panels at the side of the whole warehouse pallet tacking system.

Contact Person: XN Duan

Mobile Phone:18832797029

WhatsApp:+86 18832797029

E-mail:yuankuoduan@gmail.com

Add:Zhenggang Road, Industrial Development Zone, Botou City, Hebei Province

what is c section roll forming machine?

C-section roll forming machine, also known as a C-purlin roll forming machine, is a type of industrial machinery used in the manufacturing process of C-shaped steel sections called C-purlins. C-purlins are widely used in the construction industry as structural components in buildings, particularly in roof and wall systems.

C Bracing Section Roll Forming Machine also named C beam roll forming machine is developed to produce C beam which is for supporting the uprights rack and shelving panels at the side of the whole warehouse pallet tacking system.

Our intelligent C Bracing Section Roll Forming Machine could make various sizes of C beam according to the rack system requirements and thickness, normally 1.5-1.8mm. Uncoiling, feeding, roll forming, punching, cutting, etc. process can be automatically realized on one line. Meantime, we have the roll forming machine to make step beam, upright rack, box beam and shelf panel. All these are components of Pallet racking system.

C Bracing Section Roll Forming Machine also named C beam roll forming machine is developed to produce C beam which is for supporting the uprights rack and shelving panels at the side of the whole warehouse pallet tacking system.

The C-section roll forming machine is designed to shape and form metal coils, typically made of galvanized steel or other types of steel, into the desired C-shaped profile. The machine utilizes a series of roll forming stations that gradually bend, shape, and form the metal strip into the final C-purlin shape.

The process involves feeding the metal coil into the machine, where it passes through a series of rollers that progressively shape it. These rollers apply specific bending and forming actions to achieve the desired dimensions and profile of the C-purlin. The machine may also have additional stations for punching holes or adding other features to the C-purlin as required.