Contact Person: XN Duan

Mobile Phone:18832797029

WhatsApp:+86 18832797029

E-mail:yuankuoduan@gmail.com

Add:Zhenggang Road, Industrial Development Zone, Botou City, Hebei Province

Empowering Modern Storage Systems with Xinnuo’s Upright Beam Pallet Rack Rolling Forming Machine

As global warehousing and logistics continue to advance, the demand for reliable, high-capacity storage systems grows stronger every year. Upright beams—an essential component of pallet racking—require exceptional precision, structural strength, and consistent quality. To support these evolving needs, Xinnuo proudly presents its Upright Beam Pallet Rack Rolling Forming Machine, an intelligent and fully integrated production line designed to manufacture premium upright profiles for a wide range of warehouse storage applications.

|

Product Name |

Upright Rack Roll Forming Machine Production Line |

|

Punching |

80 ton mechanical punch press |

|

Main motor power |

18.5 kw (Polaroid) |

|

Hydraulic station |

Vane pump,5.5kw |

|

Produce speed |

6–8 m/min |

|

Shaft material |

45# Steel |

|

Brand of electrical control cabinet |

Phase sequence protector |

|

Touch screen |

Weilun or customized according to customer requirements |

|

Rolling materials |

Cr12,heat treatment HRC58–62℃ |

|

Cutting blade material |

Cr12MOV,treatment off 58 ℃ –62℃ |

|

Roller diameter |

Φ80mm |

|

Voltage |

380v 50hz 3p be customized |

|

Feeding thickness |

1.5–2.5mm |

|

Rows |

18 |

|

Board height |

600–900 mm |

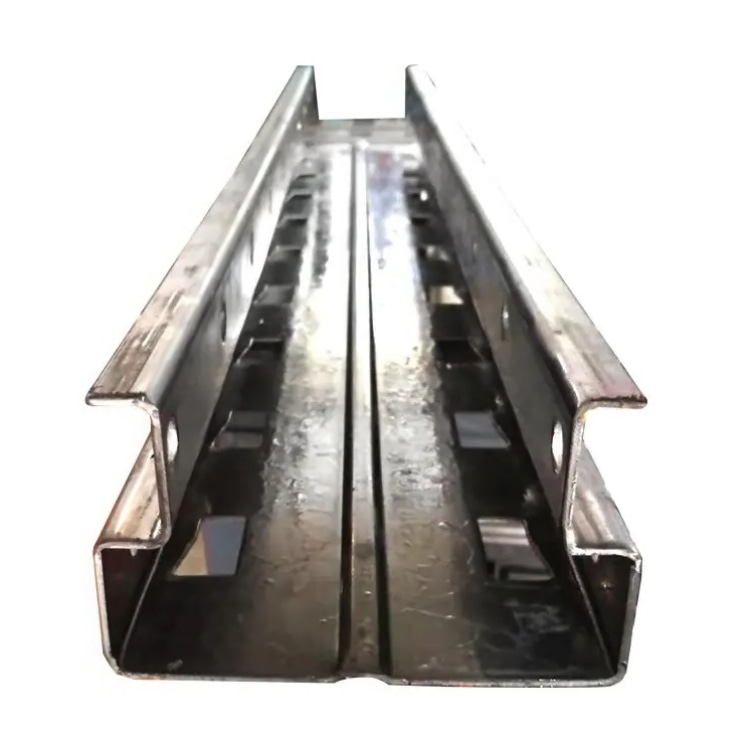

Xinnuo’s upright beam line is engineered around a seamless combination of automation, rigid mechanical structure, and precision forming technology. The production process begins with a heavy-duty automatic decoiler that ensures stable and continuous material feeding. The steel strip then enters an advanced servo-controlled punching station, where connection holes, slots, and fastening points are accurately formed according to customized specifications. Each punching die is precision-machined to guarantee clean edges and consistent alignment across all beams.

Once punched, the material enters the core forming section—an array of high-accuracy rollers made from hardened alloy steel and machined on CNC centers. These rollers gradually shape the steel into strong and uniform upright profiles while minimizing stress and deformation. A high-speed flying shear follows, cutting each beam to the exact programmed length without interrupting production, significantly improving efficiency.

The line concludes with an automatic stacking system that neatly arranges finished beams for easy packing and transport, reducing labor requirements and ensuring smooth downstream handling.

What truly sets the Xinnuo Upright Beam Pallet Rack Rolling Forming Machine apart is its exceptional adaptability and user-oriented design. Every project can be tailored to specific structural, dimensional, and loading requirements. Punching positions, hole geometries, upright sizes, and material thickness can all be rapidly adjusted through the PLC interface or via optional quick-change tooling. This ensures that each upright beam integrates perfectly into various pallet racking standards used worldwide.

To further support customers, Xinnuo offers rapid engineering service, providing complete technical drawings and profile designs within three working days. This fast response minimizes project delays and allows clients to begin production in the shortest possible time.

With robust construction, high forming accuracy, flexible customization, and fully automated control, Xinnuo’s Upright Beam Pallet Rack Rolling Forming Machine provides an efficient and dependable solution for manufacturers seeking to elevate their warehouse storage capabilities.