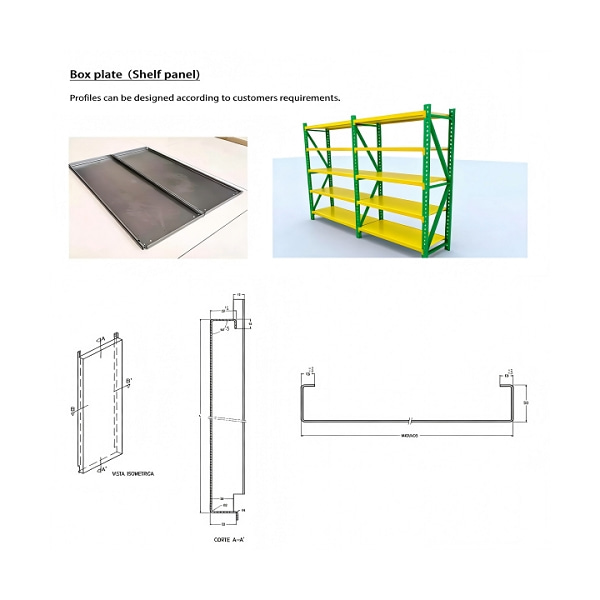

Steel box plate making roll forming machine also named supermarket shelf panel roll forming machine is developed to produce shelf panels with the product display card position. A supermarket shelf panel is used to load the goods and also display the goods information and prices. Usually, the width of the panels is various.

Contact Person: XN Duan

Mobile Phone:18832797029

WhatsApp:+86 18832797029

E-mail:yuankuoduan@gmail.com

Add:Zhenggang Road, Industrial Development Zone, Botou City, Hebei Province

Our intelligent box plate roll forming machine could make various sizes of shelf panel with thickness 0.5-0.8mm or more. Uncoiling, feeding, roll forming, punching, cutting, bending etc. process can be automatically realized on one line. Meantime, we have the roll forming machine to make step beam, upright rack and box beam. All these are components of Pallet racking system.

Steel box plate making roll forming machine also named supermarket shelf panel roll forming machine is developed to produce shelf panels with the product display card position. A supermarket shelf panel is used to load the goods and also display the goods information and prices. Usually, the width of the panels is various.

We make different solutions according to customers’ drawing, tolerance and budget, offering professional one-to-one service, adaptable for your all requirements. Whichever line you choose, the quality of SUNWAY Machinery will ensure you obtain perfectly functional profiles.

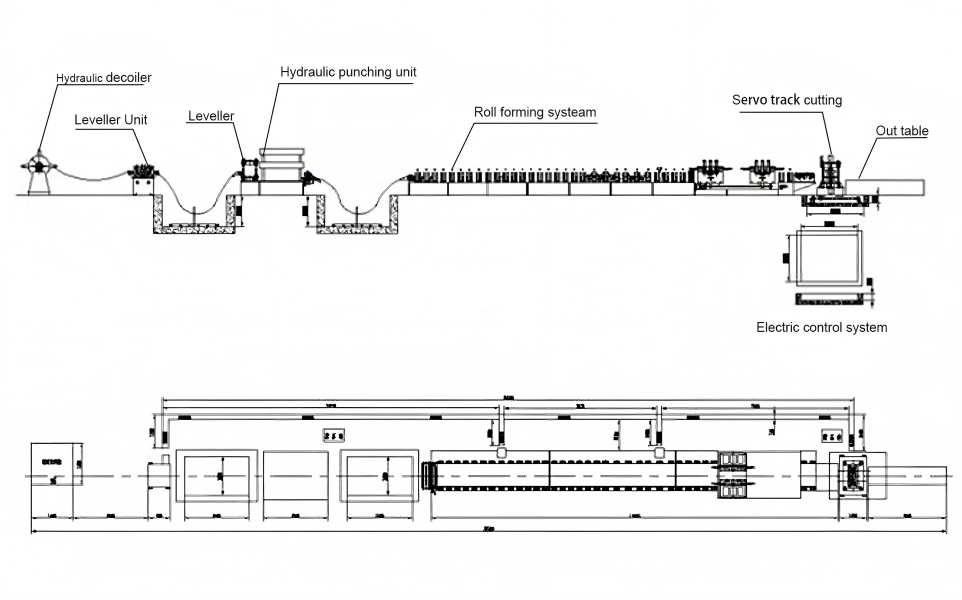

Material Feeding: The machine begins by feeding a metal strip or coil into the machine. The material is typically made of steel or aluminum and may be coated for additional protection.

Straightening: The material passes through a straightening unit that ensures it is flat and free from any deformations. This process is important to maintain the accuracy and consistency of the final pedal plates.

Roll Forming Stations: The machine consists of a series of roll forming stations, each equipped with a set of rolls that gradually shape the metal strip into the pedal plate profile. The rolls have specific contours and profiles that bend and shape the metal according to the desired design.

Progression of Forming: As the metal strip moves through the roll forming stations, each set of rolls progressively adds more shape and details to the pedal plate. The strip is guided and supported by rollers and guides to ensure accurate forming and alignment.

Cutting: Once the pedal plate profile is fully formed, a cutting unit comes into action to separate the formed pedal plates from the rest of the material. The cutting method can vary depending on the machine design and requirements, but common techniques include shear cutting or rotary cutting.

Additional Operations: After the cutting process, the pedal plates may undergo additional operations such as hole punching, embossing, or any other required modifications. These operations can be integrated into the roll forming machine or performed in separate processes.

Collection and Stacking: The finished pedal plates are then collected and stacked for further processing or packaging. Some machines may include an integrated stacking or conveyor system to facilitate this step.

Control System: The pedal plate roll forming machine is typically equipped with a control system that monitors and regulates various parameters, such as speed, length, and shape of the pedal plates. This system ensures consistent and accurate production and allows for easy operation and adjustment.

It’s important to note that the exact configuration and features of a pedal plate roll forming machine may vary depending on the specific model and manufacturer. However, the overall process described above provides a general understanding of how such a machine typically operates to produce pedal plates.