| Raw materials | Gi Steel strip or stainless steel |

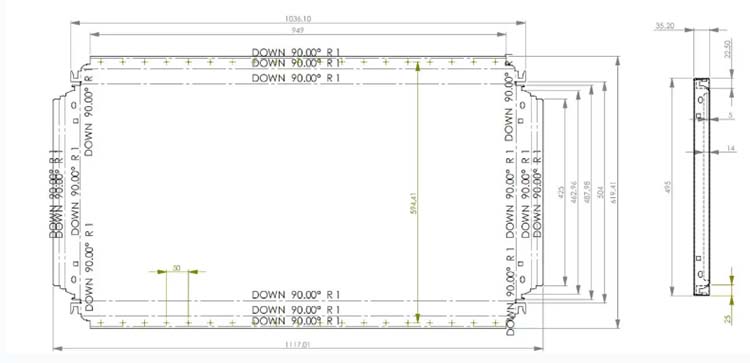

| Sizes | According with customers’ drawing |

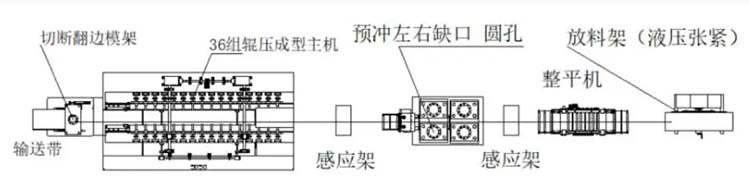

| Maximum forming speed | 30 m / min |

| Roll Forming stands | 20-125 Rollers station |

| Machine Power | ~ 35 KW |

Product Overview

Our Shelf Panel Roll Forming Machine is designed for efficient and flexible production of shelving panels for rack systems. It supports wide customization, high throughput, and automation to optimize manufacturing for various storage applications.

Key Considerations & Advantages

Customization & Flexibility

Adjust panel dimensions, material thickness, and profile shapes to meet specific storage needs.

Support for embossing, perforation, or special coatings to improve functionality and appearance.

Performance: Speed, Accuracy & Flexibility

Compare machines based on forming speed — higher speed improves production rate.

Precision ensures uniform panel dimensions to maintain quality across large batches.

Flexibility allows the machine to handle different materials (e.g. galvanized steel, stainless) and design specifications.

Automation for Efficiency

Automated feeding, quick tooling change, and in-line quality inspection reduce labor and improve consistency.

Fast changeover between panel designs allows quick response to varying customer demands.

Automation leads to higher throughput, better repeatability, and stronger competitiveness in the market.

Why Choose Our Machine

Our roll forming solutions are tailored to your production volume, drawing, and tolerance requirements.

Proven track record with shelving manufacturers: we help improve factory efficiency, reduce error, and cut manual labor.

With automation integrated into the line, you can scale your operations while maintaining high quality and cost-efficiency.

| Raw materials | Gi Steel strip or stainless steel |

| Sizes | According with customers’ drawing |

| Maximum forming speed | 30 m / min |

| Roll Forming stands | 20-125 Rollers station |

| Machine Power | ~ 35 KW |

Next Steps

Send us your shelf panel design or drawing, and we’ll provide a detailed, customized quotation. Contact our sales team to discuss how this machine can fit into your production flow and elevate your manufacturing capability.