Product Description

Product Overview

Our Auto Metal Shelves Line is a fully integrated automatic production solution designed for manufacturing high-strength metal shelves—essential for industrial warehouses, retail hypermarkets, and logistics distribution centers. From the heavy-duty forged steel frame to the integrated intelligent control system, every module is precision-engineered to deliver batch-consistent forming, labor-saving automation, and 24-hour continuous operation capability, serving as a core production backbone for metal shelving manufacturers across 85+ countries.

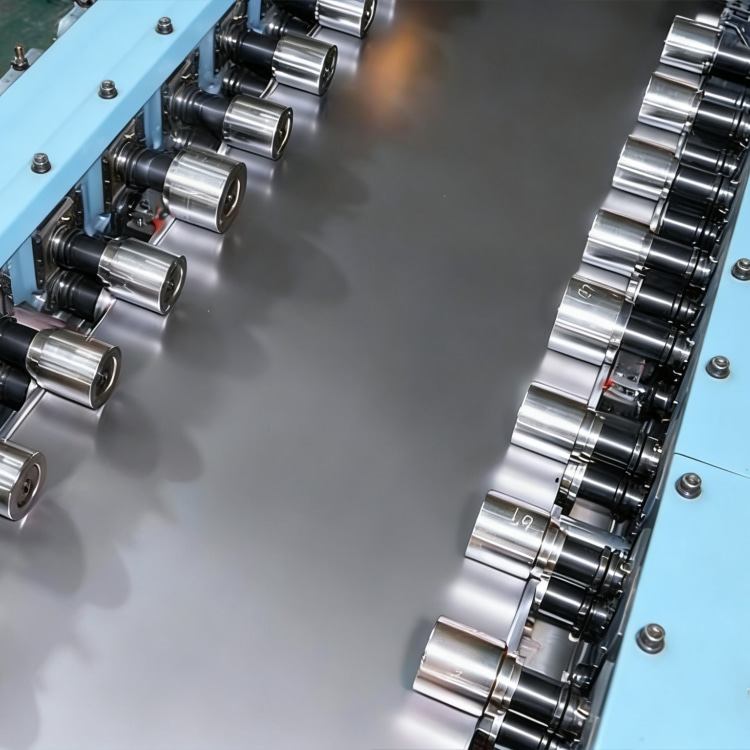

The production line is equipped with ultra-durable roller assemblies made from imported Austrian 20CrMnTi alloy steel. After vacuum carburizing and precision grinding, the roller surface hardness reaches HRC64, ensuring deformation-free forming when processing 1.2–3.5 mm high-strength Q355 carbon steel, hot-dip galvanized steel, and zinc-aluminum-magnesium coated steel. Its hydraulic quick-change roller system enables mold replacement within 20 minutes, supporting metal shelves with widths ranging from 400mm to 1200mm and heights from 1000mm to 6000mm.

Technical Advantages

High-Precision Forming System: Adopting Delta high-torque servo motors and Siemens S7-1500 PLC control, the line maintains shelf dimensional accuracy within ±0.2 mm and upright linearity below 0.35 mm/m, fully complying with GB/T 27924-2011 and ANSI MH16.3 standards for metal shelving.

Full-Process Automation: The integrated workflow covers automatic material uncoiling, pre-leveling, forming, multi-station punching, edge trimming, and even automatic stacking & packaging—eliminating 90% of manual operations, reducing total production time by 58%, and lowering material waste to less than 1.0%.

Large-Scale Productivity: A single production line can produce up to 220 sets of complete metal shelves per day, which is 4.5 times the output of traditional semi-automatic production lines, easily meeting bulk orders from retail chains and industrial logistics projects.

Safety & Quality Assurance

To adapt to high-intensity production scenarios, the line is equipped with six-group infrared safety gratings, emergency stop buttons at 3 key positions, and a safety interlock system—triggering shutdown within 0.04 seconds when risks occur. A 3D laser inspection system real-time monitors shelf upright straightness, beam load-bearing performance, and surface defects, ensuring every finished shelf can stably bear 1500 kg per layer.

Material Compatibility

The line specializes in processing high-performance metal materials, including 1.2–3.5 mm Q355/Q420 carbon steel, hot-dip galvanized steel (zinc layer ≥ 180g/m²), and color-coated steel sheets. Through adaptive roller pressure control (adjustable within 8–22 MPa) and circulating water cooling, it preserves material toughness and anti-corrosion performance, making finished shelves suitable for outdoor stockyards, humid workshops, and chemical storage facilities.

One-Stop Global Service

We provide customized services covering the entire production line lifecycle, tailored for global clients:

Pre-sales consulting: Multilingual technical support (English, German, Russian, Portuguese), on-site factory layout planning, and shelving specification optimization based on local load-bearing standards.

Sales support: Heavy-equipment dedicated packaging, industrial production line customs clearance agency, on-site installation & commissioning, and 7-day in-depth training for operation, maintenance, and quality inspection teams.

After-sales service: 24/7 on-call technical engineers (key regions respond within 48 hours), 36-month warranty for core components (rollers, servo motors, PLC), lifetime maintenance guidance, and free system upgrades for 5 years.

Certifications

CE | ISO9001 | SGS | TUV | ANSI MH16.3 | UL | GB/T 27924-2011

Typical Applications

Heavy-duty metal shelf production for industrial warehouses

Retail metal shelf manufacturing for supermarkets and hypermarkets

Corrosion-resistant metal shelves for cold-chain and chemical storage

Modular metal shelves for logistics distribution centers and e-commerce warehouses