| Specifications | |

|---|---|

| Raw Material | HCR Coil / Carbon Steel Coil, GI Coil, and so on |

| Material Thickness | 0.8 ~ 2.5 mm |

| Profile | 90 / 100 / 120 * 70 mm |

| Complete Line Working Speed | 2 ~ 15 m/min |

| Decoiler Capacity | 5 Ton |

| Punch Press Capacity | 110 Ton |

| Roll Forming Stands | 18 – 22 stands |

| Motor Power | 18.5 kW × 2 |

| Roller Material | CR12 MOV, Hardness 58–62° |

| Shaft | 75 mm diameter, 40Cr |

| Hydraulic Motor Power | 5.5 kW |

| Servo Track Motor Power | 3 kW |

Product Overview

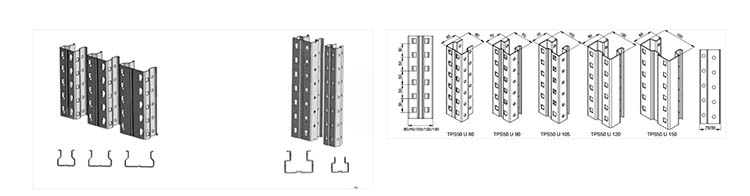

Our Warehouse Shelf Upright Roll Forming Machine (also called Pallet Racking Roll Forming Machine) is built to produce upright frames, box beams, and step beams — the core structural elements of pallet racking systems. With a smart cantilever design, the machine can automatically adjust both width and height via motors — simply input your required dimensions into the touch screen, and the machine will switch profile size in seconds.

Technical Highlights

Material thickness: 1.5 – 3.0 mm

Compatible materials: Cold-rolled steel, Galvanized coil, PPGI, Carbon steel, Stainless steel, and Aluminum

Process: Fully automatic line that performs uncoiling, servo feeding, punching, roll forming, and cutting

Quality: Profiles meet ISO, CE, and FEM standards — suitable for warehouse, supermarket, industrial, or home racking systems

| Specifications | |

|---|---|

| Raw Material | HCR Coil / Carbon Steel Coil, GI Coil, and so on |

| Material Thickness | 0.8 ~ 2.5 mm |

| Profile | 90 / 100 / 120 * 70 mm |

| Complete Line Working Speed | 2 ~ 15 m/min |

| Decoiler Capacity | 5 Ton |

| Punch Press Capacity | 110 Ton |

| Roll Forming Stands | 18 – 22 stands |

| Motor Power | 18.5 kW × 2 |

| Roller Material | CR12 MOV, Hardness 58–62° |

| Shaft | 75 mm diameter, 40Cr |

| Hydraulic Motor Power | 5.5 kW |

| Servo Track Motor Power | 3 kW |

Application & Capability

This roll-forming system is ideal for manufacturing complete pallet racking system components. In addition to upright posts, we provide machines for Box Beam Roll Forming, Step Beam Roll Forming, and Shelf Panel Roll Forming, covering all structural elements required in storage systems. Whether for high-bay warehouses, industrial shelving, or retail racks, our machines deliver high-precision, high-efficiency production.

Export Experience

We have successfully exported our pallet racking roll forming machines to Mexico, Peru, and the UK. Our global experience demonstrates our ability to deliver reliable, customized machines to meet different market needs.

Customization & Service

We offer one-on-one service to design a solution based on your drawings, tolerance requirements, and budget. Choose the line you need — whether Upright, Box Beam, Step Beam, or Shelf Panel — and Linbay Machinery will ensure you receive fully functional, precisely formed profiles that match your specifications.