Xinnuo Rack Partition Beam Roll Forming Machine: Precision for Organized Warehousing

In modern warehouses, where efficient space utilization and organized goods storage are critical, rack partition beams play a pivotal role—they divide large rack bays into manageable compartments, preventing goods from mixing and optimizing vertical storage. Xinnuo’s Rack Partition Beam Roll Forming Machine is engineered exclusively for producing these essential components, blending 25+ years of roll forming expertise with tailored innovations to meet the diverse needs of global storage equipment manufacturers. As a flagship product from Hebei Xinnuo, an ISO 9001 and CE-certified brand trusted in 60+ countries, this machine empowers clients to create high-quality partition beams that enhance warehouse efficiency, serving industries from e-commerce and retail to automotive and logistics.

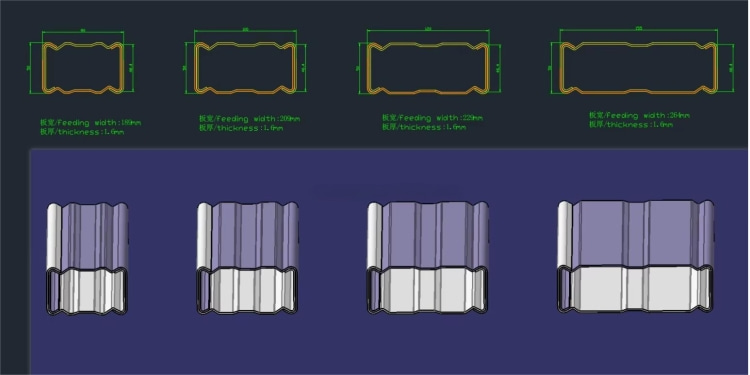

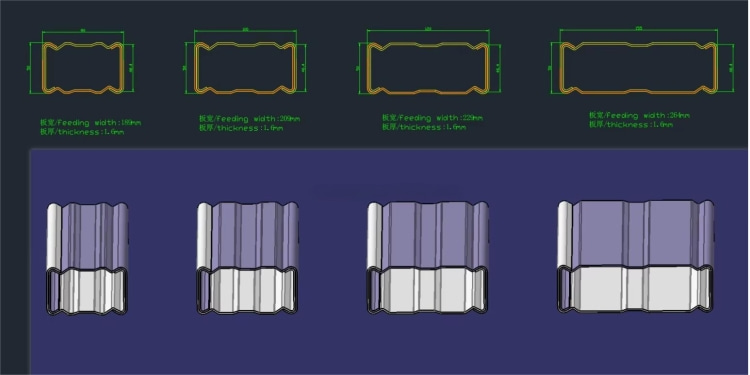

What sets this machine apart is its deep understanding of the unique requirements of rack partition beams. Unlike standard structural beams, partition beams demand consistent cross-sections, smooth surfaces, and precise mounting features to ensure easy installation and reliable load support for small to medium-sized goods. Xinnuo’s machine excels here by processing 0.8-3.0mm thick high-grade materials, including galvanized steel, cold-rolled steel, and colored steel coils—materials chosen for their corrosion resistance and structural rigidity. It specializes in forming a wide range of partition beam types, from U-section beams for light-duty retail shelving to reinforced C-section beams for industrial parts storage, all with dimensional tolerance of ±0.2mm and burr-free edges, ensuring perfect compatibility with various rack systems.

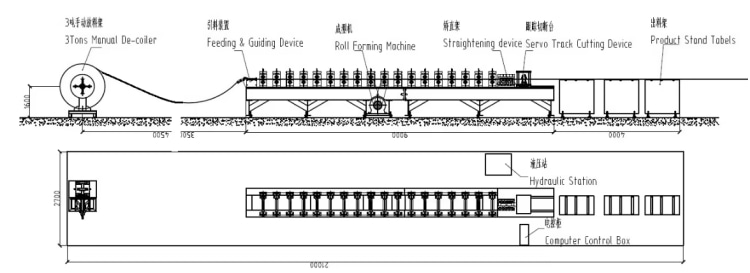

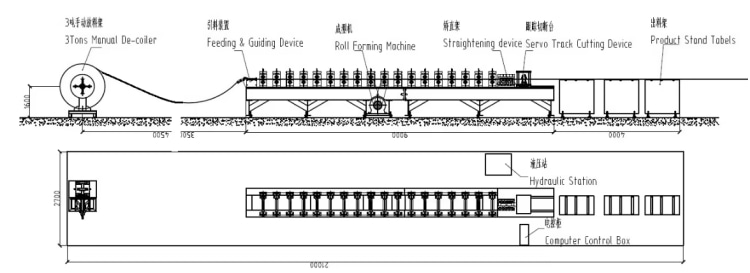

Efficiency is at the heart of the machine’s design, addressing the production challenges faced by modern manufacturers. Equipped with a Mitsubishi PLC control system and a 7-inch touchscreen HMI, it automates the entire production workflow: a 5-ton hydraulic decoiler with automatic coil centering feeds materials stably, a precision leveling unit eliminates coil warpage, a high-speed punching module creates accurate mounting holes (critical for quick assembly), a roll forming section shapes the material in one seamless pass, and a servo-driven flying cutting device trims beams to exact lengths (0.6-5m) without halting production. This full automation slashes labor requirements from 3 workers to 1, reduces labor costs by 65%, and boosts production speed to 10-18 meters per minute—far outpacing semi-automatic alternatives. Clients report a 50% increase in monthly output within the first quarter, a game-changer for meeting tight order deadlines during peak logistics seasons.

Customization is another key strength, designed to adapt to the varied needs of the storage industry. Xinnuo’s R&D team of 50+ engineers collaborates closely with clients to tailor roller configurations, beam profiles, and punching patterns to specific project demands. Whether a client needs partition beams for cold-chain warehouses (requiring anti-rust coatings) or automated picking systems (demanding ultra-precise dimensions), the machine can be programmed to produce 100+ custom designs with minimal setup time (under 5 minutes). This flexibility allows manufacturers to cater to niche markets and expand their product portfolios without investing in multiple pieces of equipment.

Durability and global compliance ensure long-term value and market access. The machine features a 6.5-ton reinforced welded steel frame with anti-vibration damping pads, supporting 24/7 continuous operation without compromising stability. Its 22 hardened GCR15 steel rollers (58HRC hardness) with chrome plating resist wear and tear, extending service life by 40% compared to standard rollers. Additionally, it holds TUV, ANSI, and ISO certifications, fully complying with strict safety and quality standards in the EU, North America, and Southeast Asia—removing barriers for manufacturers targeting global markets.

Beyond the equipment itself, Xinnuo’s comprehensive support ecosystem transforms a machine purchase into a strategic partnership. Clients receive free on-site installation, personalized operator training (covering operation, maintenance, and troubleshooting), 24/7 technical support (via remote assistance or on-site service in key regions), and a 1-year standard warranty (extendable to 3 years). A global spare parts warehouse ensures quick delivery of replacement components, minimizing downtime. These value-added services translate to tangible business results: a 7% reduction in material waste due to precise forming, and a return on investment within 9-12 months.

As the demand for organized, efficient warehousing grows—driven by the rise of omnichannel retail and intelligent logistics—Xinnuo remains committed to innovation. We invest 15% of annual revenue in R&D, focusing on AI-integrated control systems that predict maintenance needs and IoT-enabled monitoring for real-time production tracking. For manufacturers seeking to gain a competitive edge in the storage equipment market, Xinnuo’s Rack Partition Beam Roll Forming Machine is more than a production tool—it’s a reliable partner that enhances product quality, streamlines operations, and strengthens customer trust. Whether you’re a small-scale shelving manufacturer or a large industrial supplier, this machine empowers you to build storage systems that meet the evolving needs of the global market.