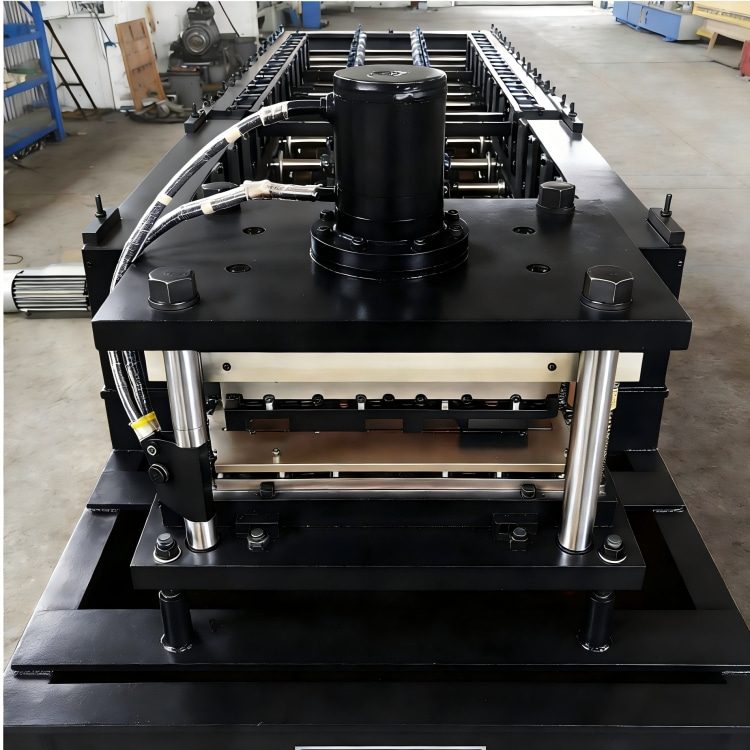

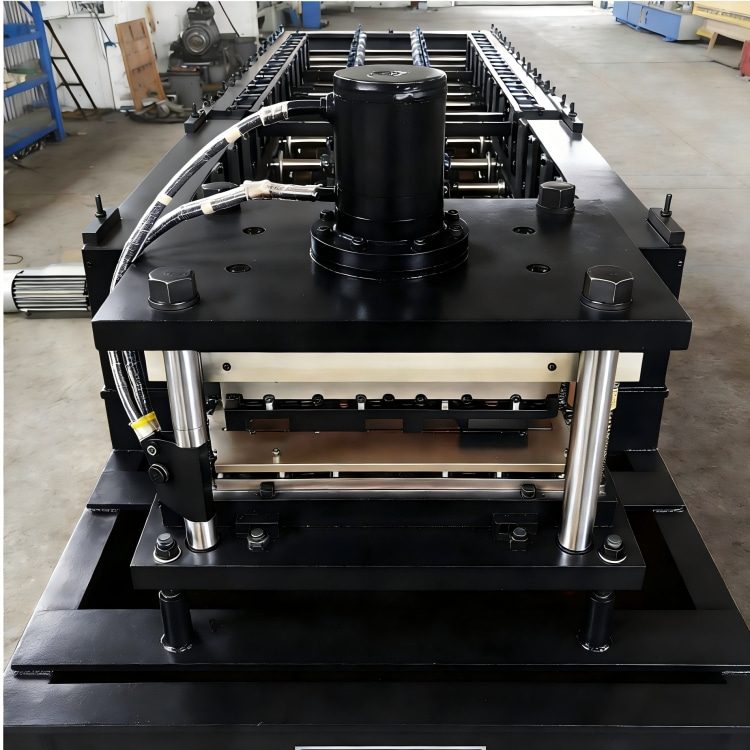

Product Overview

This machine is specialized in producing high-precision, smooth-surface panels for supermarket storage racks. It integrates full-auto workflow from decoiling to cutting, paired with advanced PLC control and high-hardness rollers, ensuring consistent quality that meets the neat appearance and load-bearing needs of supermarket shelves.

Core Technical Specifications

-

Raw material: Cold-rolled steel, Galvanized steel (optional stainless / color-coated steel)

-

Material thickness: 1.5 – 3.0 mm

-

Roller material: GCr15 (or optional Cr12) alloy steel, heat treated (quenched / hardened)

-

Roller hardness: HRC 58 – 62° (depending on heat treatment)

-

Number of forming stations: 16 – 28 stations (profile dependent)

-

Forming (line) speed: 5 – 15 m/min (depending on profile & configuration)

-

Main motor power:15 – 22 kW (depending on model)

-

Cutting / Shearing system: Hydraulic cutting (or saw-cut); cutting blades made of heat-treated Cr12 / Cr12MoV

-

Control system: PLC control (Siemens / Panasonic / Delta optional) — supports automatic forming, punching, cutting, length & quantity control

-

Decoiler: Manual or hydraulic decoiler (capacity configurable, e.g. 3t–5t)

-

Material width: As per customer’s profile drawing / specification

-

Power supply / Voltage: 380 V, 50 Hz, three-phase (customizable per customer requirement)

|

Parameter

|

Specification

|

|

Raw material

|

Cold-rolled steel,Galvanized steel (optional stainless / color-coated steel)

|

|

Material thickness

|

1.5 – 3.0 mm

|

|

Roller material

|

GCr15 (or optional Cr12) alloy steel,heat treated (quenched / hardened)

|

|

Roller hardness

|

HRC 58 – 62° (depending on heat treatment)

|

|

Number of forming stations

|

16 – 28 stations (profile dependent)

|

|

Forming (line) speed

|

5 – 15 m/min (depending on profile & configuration)

|

|

Main motor power

|

15 – 22 kW (depending on model)

|

|

Cutting / Shearing system

|

Hydraulic cutting (or saw-cut);cutting blades made of heat-treated Cr12 / Cr12MoV

|

|

Control system

|

PLC control (Siemens / Panasonic / Delta optional) — supports automatic forming,punching,cutting,length & quantity control

|

|

Decoiler

|

manual or hydraulic decoiler (capacity configurable,e.g. 3t–5t)

|

|

Material width

|

As per customer’s profile drawing / specification

|

|

Profile types

|

Upright rack columns / shelf upright posts / pallet rack uprights / warehouse shelving uprights

|

|

Power supply / Voltage

|

380 V,50 Hz,three-phase (customizable per customer requirement)

|

Key Product Advantages

1. Precision & Aesthetics: High-hardness rollers and 16-28 adjustable stations ensure smooth panel surfaces and ±0.5mm accuracy, fitting supermarket shelf’s neat appearance demand.

2. Intelligent Sync: PLC control realizes seamless coordination of processes, reducing burrs and improving product consistency for supermarket daily storage use.

3. Safety & Stability: Equipped with real-time fault monitoring and emergency stop devices, safeguarding continuous production for supermarket rack manufacturers.

Quality & Safety Assurance

Compliant with CE, ISO9001:2015 standards, all components undergo rigorous testing, ensuring panels resist deformation and meet supermarket long-term storage needs.

Global Service Support

Provide multilingual consultation, on-site installation & commissioning, operator training and 24/7 after-sales support, ensuring worry-free use worldwide.

Typical Applications

Widely used in producing panels for supermarket grocery racks, daily necessities shelves, fresh food storage racks and checkout counter auxiliary shelves.