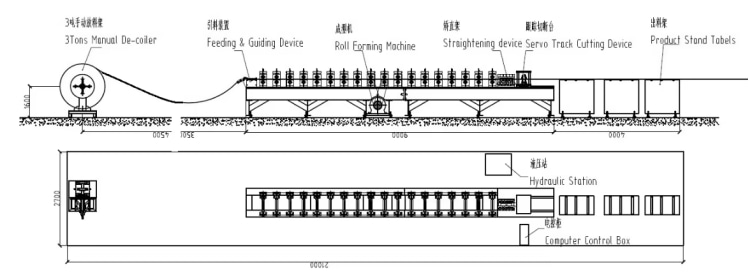

Product Overview

The Upright Box Beam Roll Forming Machine is a professional automated production equipment dedicated to manufacturing high-precision and high-strength upright box beams. As a core device in the storage rack and heavy-duty logistics equipment manufacturing industry, it integrates decoiling, automatic feeding, precision punching, continuous roll forming, and high-precision cutting into a seamless and efficient production workflow. Equipped with advanced intelligent control technology and high-quality core components, this machine ensures stable, consistent, and large-batch production of upright box beams, perfectly meeting the strict load-bearing and assembly requirements of industrial warehouses, large-scale logistics distribution centers, and heavy-duty storage facilities. It is highly recognized by global storage equipment manufacturers for its reliable operation, excellent forming performance, and strong customization capabilities.

Core Technical Specifications

-

Raw material: Cold-rolled steel, Galvanized steel (optional stainless / color-coated steel)

-

Material thickness: 1.5 – 3.0 mm

-

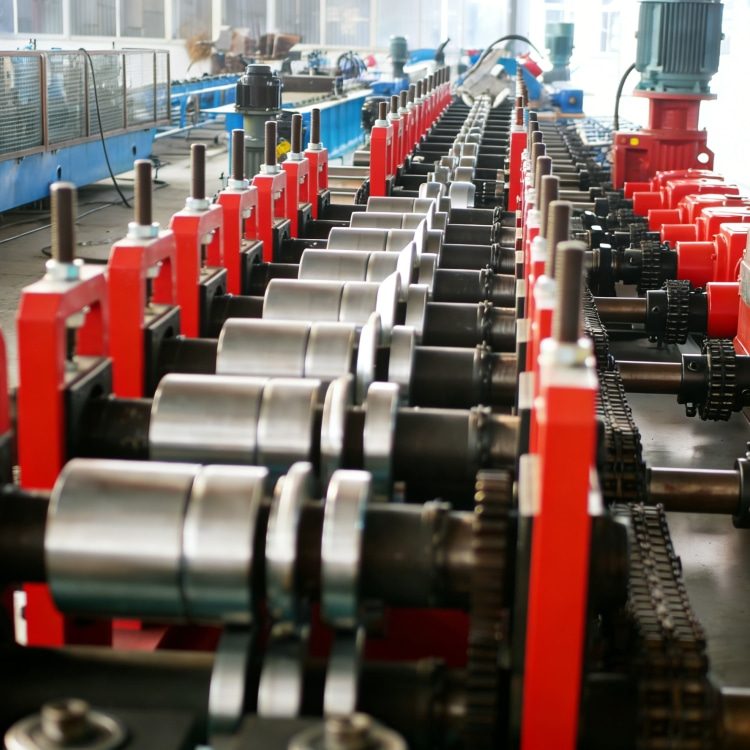

Roller material: GCr15 (or optional Cr12) alloy steel, heat treated (quenched / hardened)

-

Roller hardness: HRC 58 – 62° (depending on heat treatment)

-

Number of forming stations: 16 – 28 stations (profile dependent)

-

Forming (line) speed: 5 – 15 m/min (depending on profile & configuration)

-

Main motor power:15 – 22 kW (depending on model)

-

Cutting / Shearing system: Hydraulic cutting (or saw-cut); cutting blades made of heat-treated Cr12 / Cr12MoV

-

Control system: PLC control (Siemens / Panasonic / Delta optional) — supports automatic forming, punching, cutting, length & quantity control

-

Decoiler: Manual or hydraulic decoiler (capacity configurable, e.g. 3t–5t)

-

Material width: As per customer’s profile drawing / specification

-

Profile types: Upright rack columns / shelf upright posts / pallet rack uprights / warehouse shelving uprights

-

Power supply / Voltage: 380 V, 50 Hz, three-phase (customizable per customer requirement)

Global One-Stop Service

Pre-sales Consulting

We provide multilingual technical support (English, German, Russian, Spanish, Arabic), on-site factory layout planning, and personalized production solutions based on customers' specific upright box beam drawings, material requirements, production scales, and regional power standards.

Sales Support

Professional packaging is used to ensure the safe transportation of equipment. We provide complete industrial equipment customs clearance documents and arrange experienced engineers to carry out on-site installation, commissioning, and debugging. Systematic training on machine operation, maintenance, and quality control is also provided for customer teams.

After-sales Service

24/7 online technical assistance is available to solve customer problems in a timely manner. On-site maintenance support is provided within 48 hours in key regions. We offer a long-term warranty for core components of the machine, provide lifelong maintenance guidance, and free software upgrade services to ensure the continuous and stable operation of the equipment.

Typical Applications

-

Production of upright box beams for heavy-duty industrial storage racks

-

Manufacturing of precision upright box beams for large-scale logistics distribution centers

-

Customized production of high-strength upright box beams for high-end commercial storage facilities

-

Production of special environment (cold-chain, chemical) resistant upright box beams for special industries