Product Description

Product Overview

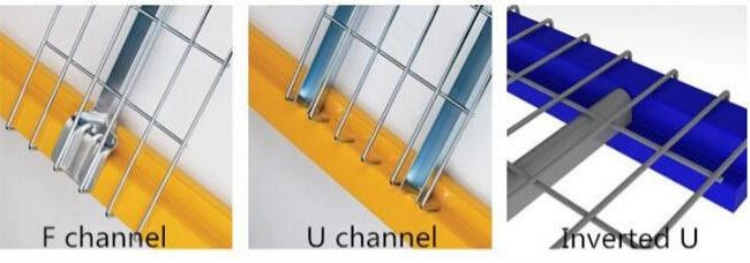

Our Wire Mesh Decking U Channel Roll Forming Machine is exclusively engineered to fulfill the production requirements of U-shaped edge channels for wire mesh decking—an essential component for reinforcing warehouse rack layers, supermarket shelves, and logistics platforms. From the reinforced mechanical chassis to the intelligent control unit, every part is precision-tailored to deliver stable forming, high compatibility, and long-lasting reliability, serving as a cornerstone equipment for wire mesh decking manufacturers globally.

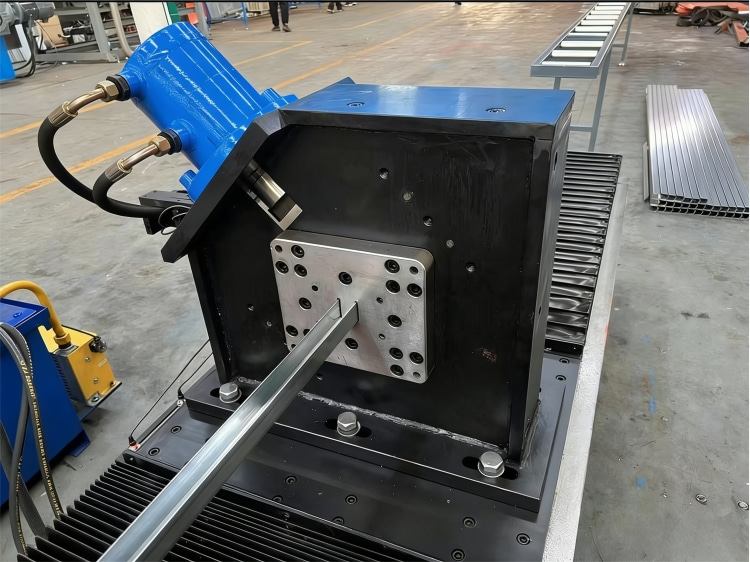

The machine is equipped with a wear-resistant roller assembly made from imported Japanese alloy steel. After carburizing and quenching treatment, the roller surface hardness achieves HRC63, ensuring consistent forming precision when processing 1.5–3.2 mm galvanized steel, high-strength carbon steel, and weather-resistant steel sheets. Its quick-change roller structure allows for mold replacement within 28 minutes, significantly enhancing production efficiency for U channels of different widths (ranging from 40mm to 120mm).

Technical Advantages

Precision-Controlled Forming System: Equipped with Panasonic servo motors and Siemens S7-1200 PLC control, the machine maintains U channel dimensional accuracy within ±0.25 mm and edge straightness below 0.4 mm/m, fully complying with the strict standard of ISO 1461-2009.

Integrated Forming & Deburring: The one-stop process of online forming, punching, and automatic deburring eliminates secondary processing procedures, reducing total production time by 55% and improving product surface smoothness.

High-Efficiency Production: A single machine can produce up to 180 sets of U channel components per day, which is 3.5 times the output of traditional manual forming lines, easily meeting large-batch order demands.

Safety & Quality Assurance

To ensure operator safety and product consistency, the machine integrates dual-beam infrared safety gratings that trigger an automatic stop within 0.06 seconds when foreign objects intrude. A laser dimension inspection system monitors key parameters (width, thickness, straightness) in real-time, automatically marking and sorting non-conforming products. This guarantees stable and high-quality output even during 24/7 continuous production.

Material Compatibility

The machine supports a variety of metal materials, including hot-dip galvanized steel, cold-rolled steel, and zinc-aluminum alloy coated steel sheets with thicknesses of 1.5–3.2 mm. Through advanced constant-pressure roller control and temperature adjustment technology, it effectively preserves the material’s anti-corrosion coating, enhances the U channel’s load-bearing capacity (up to 800 kg per meter), and extends the service life of finished wire mesh decking—perfect for dry warehouses, cold storage, and outdoor logistics platforms.

One-Stop Global Service

We provide all-round foreign trade and technical services, including:

Pre-sales consulting: Multilingual technical support (English, French, Russian, Arabic, etc.), customized production line planning, and U channel specification optimization proposals.

Sales support: Professional handling of customs clearance, international shipping (by sea/air/land), on-site installation and commissioning, as well as systematic training for operators and maintenance teams.

After-sales service: 24/7 online technical assistance, 30-month warranty for core components (rollers, servo motors, PLC), lifetime maintenance guidance, and free software upgrade services for 5 years.

|

Description

|

Offered specification

|

|

Roll forming machine

|

|

|

Rolling speed

|

0-30m/min

|

|

Rolling thickness

|

1.5mm-2.0mm

|

|

Raw material

|

Galvanized steel

|

|

Main Motor

|

11KW

|

|

Effective width

|

As drawing

|

|

Feeding Coil width

|

As profile

|

|

Roller stations

|

About 11 stations

|

|

Roller material

|

Gcr15

|

|

Shaft diameter

|

Φ60mm

|

|

Transmission

|

Chain Driven

|

|

Material of chain

|

45# forged steel with frequency quenching,12A

|

|

Material of cutting

|

Cr12Mov with quench HRC58-62°

|

|

Tolerance

|

+ -1.5mm

|

|

Hydraulic station

|

7.5kw

|

Certifications

CE | ISO9001 | SGS | TUV | ANSI | AS/NZS

Typical Applications

Wire mesh decking U channel production for warehouse racks

Reinforcement channel manufacturing for supermarket shelf layers

U-shaped edge channel production for cold chain and logistics platforms

Heavy-duty wire mesh decking components for industrial storage